Why Manufacturers Rely on SiC Sealing Ring

SiC Sealing Rings are vital for manufacturers due to their durability, wear resistance, and thermal stability, ensuring reliable performance in extreme conditions.

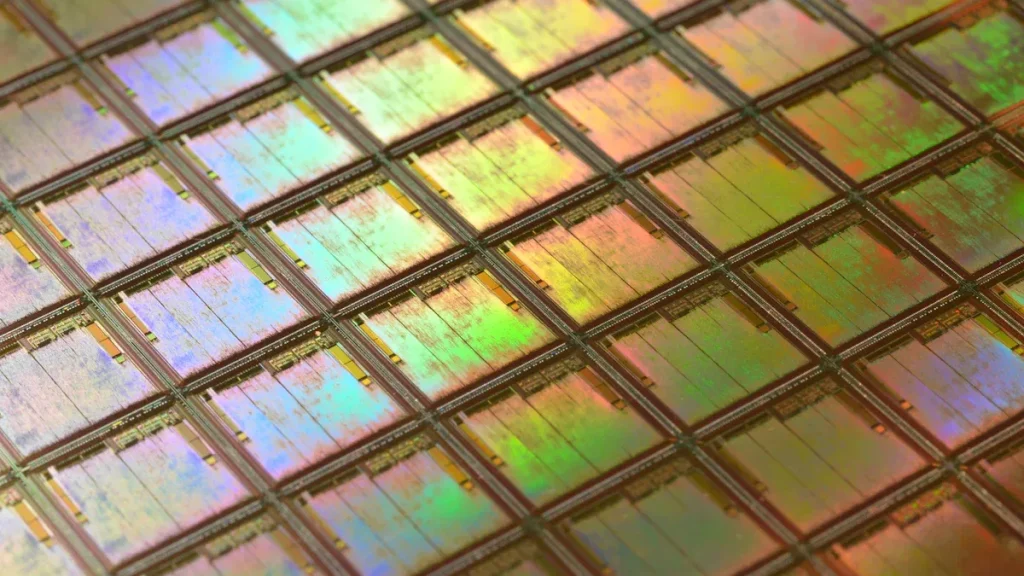

High-Performance SiC Epitaxial Wafers Transforming Semiconductor Industry

Discover how Silicon Carbide Epitaxial Wafer advancements in 2025 are driving efficiency, cost optimization, and innovation in EVs, renewable energy, and power electronics.

TaC Coating Guide Rings: Built for Tough Conditions

TaC Coating Guide Rings offer exceptional durability, thermal stability, and chemical resistance, making them ideal for demanding industrial applications.

What Makes the Contiguous Wafer Boat Ideal for Semiconductor Manufacturing in 2025

The Contiguous Wafer Boat boosts semiconductor manufacturing in 2025 with secure wafer handling, high-temperature resistance, and customizable designs.

Why SiC Wafer Boat Is the Best Solution?

SiC Wafer Boat offers unmatched thermal stability, chemical resistance, and durability, solving diffusion challenges and improving semiconductor manufacturing efficiency.

Research – Backed: The Impact of TAC Coating on Medical Device Performance Metrics

TAC Coating enhances medical device performance with superior durability, biocompatibility, and anti-corrosion properties, ensuring safety and reliability.

Why is semiconductor graphite important for wafer production?

Semiconductor graphite is vital for wafer production due to its thermal stability, chemical resistance, and durability, ensuring precision and efficiency.

Essential Care Tips for SiC Guide Rings

Maintain SiC Guide Rings with regular cleaning, inspections, and proper storage to ensure durability, reduce friction, and enhance fishing performance.

Top Suppliers of Semiconductor Graphite Products in 2025

Explore the top suppliers of semiconductor graphite in 2025, offering high-purity, customizable solutions for advanced semiconductor manufacturing needs.

What are the uses of SiC Coating Collector Top in semiconductor processing?

SiC coating enhances semiconductor processing by providing thermal stability, corrosion resistance, and durability, ensuring high-purity and efficient manufacturing.