What Makes Silicon Carbide Superior to Other Semiconductor Materials

Silicon carbide excels in high-power, high-temperature applications with superior thermal conductivity, wide bandgap, and durability over silicon and GaN.

CarPro SiC Coating vs Other Ceramic Coatings in 2025

Compare CarPro SiC Coating to other ceramic coatings in 2025. Discover its durability, hydrophobic properties, and why it stands out for long-term protection.

SiC Coating Car Benefits Compared to SiO2 Ceramic Coatings

SiC coating car solutions offer superior durability, chemical resistance, and long-term value compared to SiO2 coatings, ideal for luxury and high-performance vehicles.

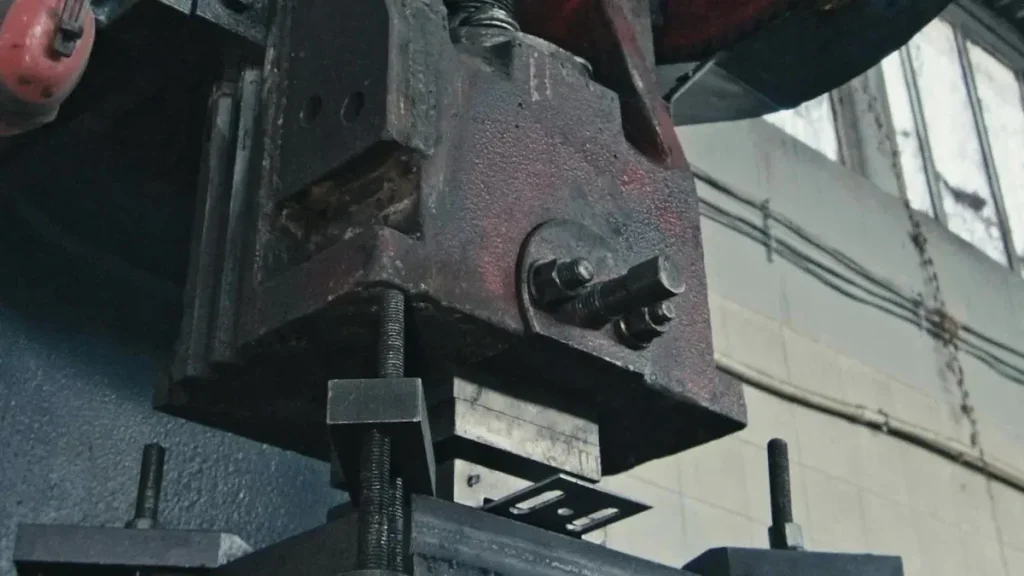

Cost – Benefit Analysis of TAC Coating in Automotive Component Production

Analyze the cost-benefit of TAC Coating in automotive production. Discover its durability, reduced maintenance costs, and ROI for enhanced efficiency.

New Horizons: TAC Coating’s Emerging Role in Automotive Component Design

TAC Coating enhances automotive design by improving durability, thermal stability, and sustainability, making vehicles lighter, safer, and more efficient.

TAC Coating: A Key Solution for Durability in Automotive Parts

TAC Coating enhances automotive parts’ durability by resisting wear, heat, and corrosion. It reduces maintenance costs and ensures long-lasting performance.

How TAC Coating Enhances the Performance of Automotive Parts

TAC Coating enhances automotive parts by reducing friction, improving wear resistance, and boosting durability, ensuring optimal performance under stress.

5 Reasons Why TAC Coating is a Must – Have for Automotive Components

TAC Coating boosts durability, resists corrosion, and protects automotive parts from wear, UV rays, and chemicals, ensuring long-term performance and value.

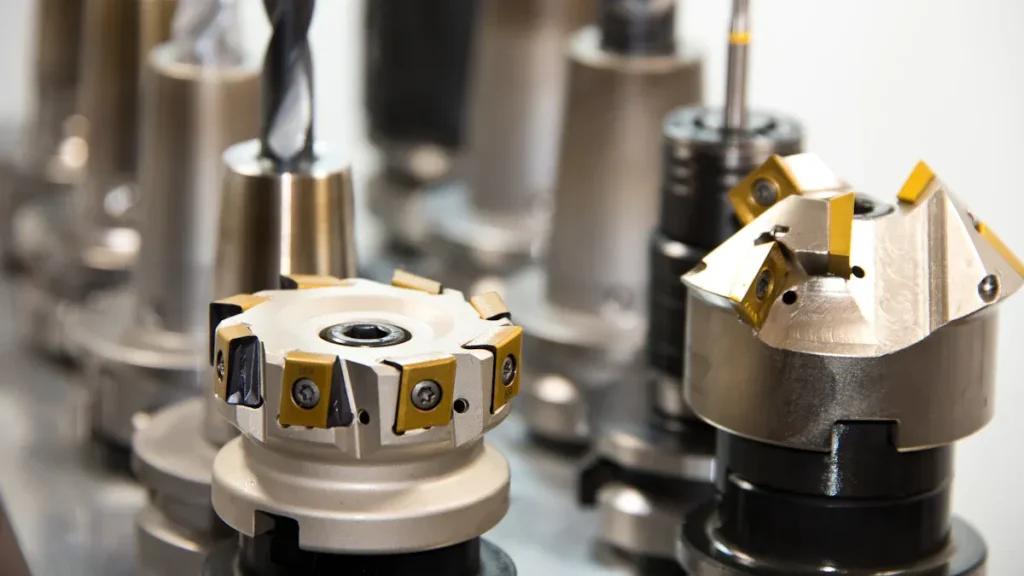

The Expanding Role of TAC Coating in Mechanical Machining Applications

TAC Coating enhances machining with superior durability, thermal stability, and chemical resistance, making it ideal for aerospace, automotive, and electronics.

10 Ways TAC Coating is Being Used in Mechanical Machining Today

Discover 10 innovative ways TAC Coating enhances machining by improving tool durability, heat resistance, cutting efficiency, and precision in modern processes.