Graphite Rotors & Vanes: Enabling Energy-Efficient Cooling in EV Motors

Graphite Rotors & Vanes enhance EV motor cooling with superior thermal conductivity, lightweight design, and durability, boosting energy efficiency and performance.

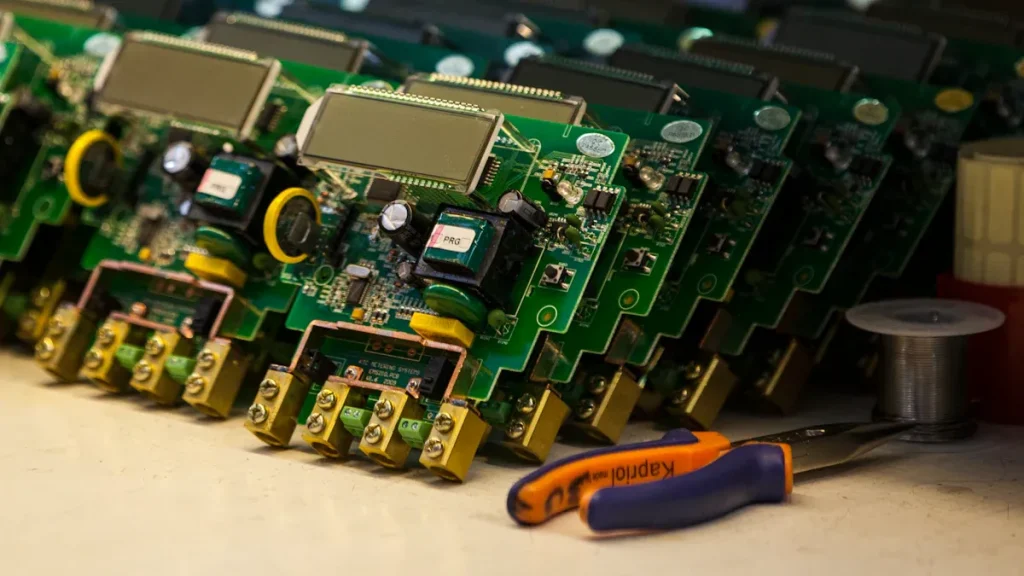

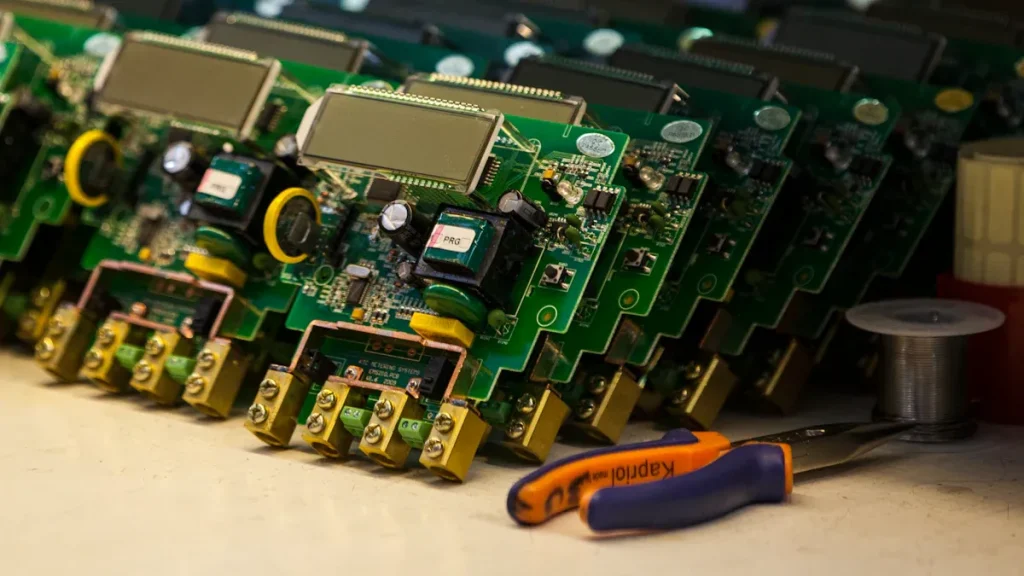

Why Automotive OEMs Are Adopting Graphite Electrodes for Lithium-Ion Battery Production

Automotive OEMs adopt graphite electrodes for lithium-ion batteries due to their superior conductivity, stability, and role in enhancing EV performance.

Unlocking the Benefits of TaC Coating for Aerospace Turbines and Heat Shields

TaC Coating enhances aerospace turbines and heat shields with superior heat resistance, durability, and efficiency, ensuring safety and performance in extreme conditions.

TaC Coating: The Shield for Aerospace Components in High-Temperature Environments

TaC Coating offers unmatched thermal resistance, durability, and chemical stability, protecting aerospace components from extreme heat and wear in harsh environments.

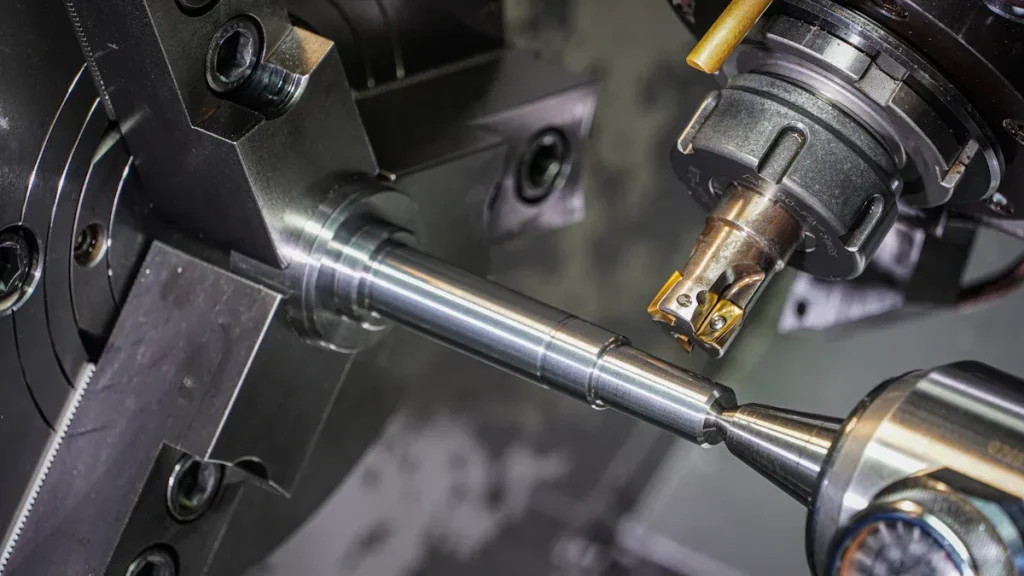

5 Steps to Ensure Proper Installation of Graphite Rotors in Compressor Systems

Follow these 5 steps to install graphite rotors in compressor systems, ensuring proper alignment, secure fastening, and optimal performance without damage.

Why Automotive OEMs Are Switching to CVD-Coated Turbocharger Components

Automotive OEMs prefer CVD-coated turbocharger components for their superior heat resistance, durability, and efficiency, ensuring better performance and longevity.

SiC Coating for Car Brake Systems: Boosting Thermal Stability in Electric Vehicles

SiC Coating enhances EV brake systems by improving thermal stability, heat dissipation, and wear resistance, ensuring safety and efficiency under extreme conditions.

CVD Coating Innovations: Protecting EV Charging Ports from Corrosion and Wear

CVD Coating enhances EV charging port durability by preventing corrosion and wear. Its advanced technology ensures long-lasting performance and reduced maintenance.

How TaC Coating Enhances Durability in High-Temperature EV Battery Components

TaC Coating boosts EV battery durability with thermal resistance, wear protection, and corrosion resistance, ensuring reliability in high-temperature conditions.

How TaC Coating Enhances Durability in High-Temperature EV Battery Components

TaC Coating boosts EV battery durability with thermal resistance, wear protection, and corrosion resistance, ensuring reliability in high-temperature conditions.