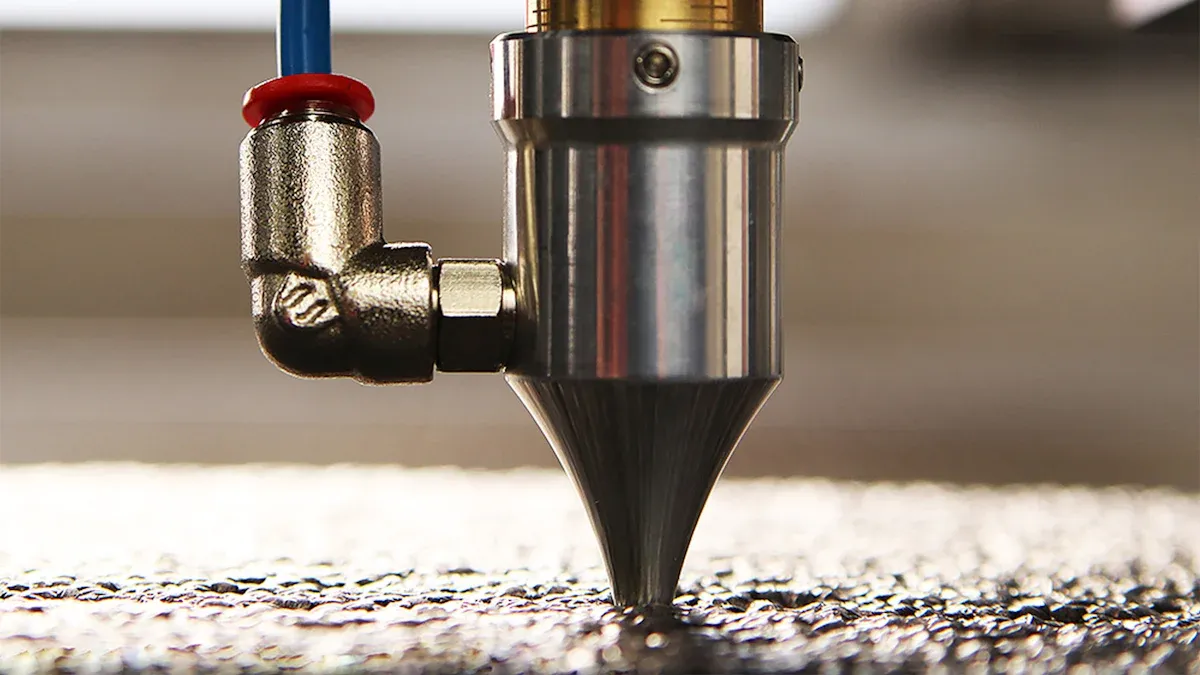

SiC nozzles offer outstanding wear resistance in abrasive jet machining. Manufacturers like Ningbo VET Energy Technology Co., Ltd benefit from their durability.

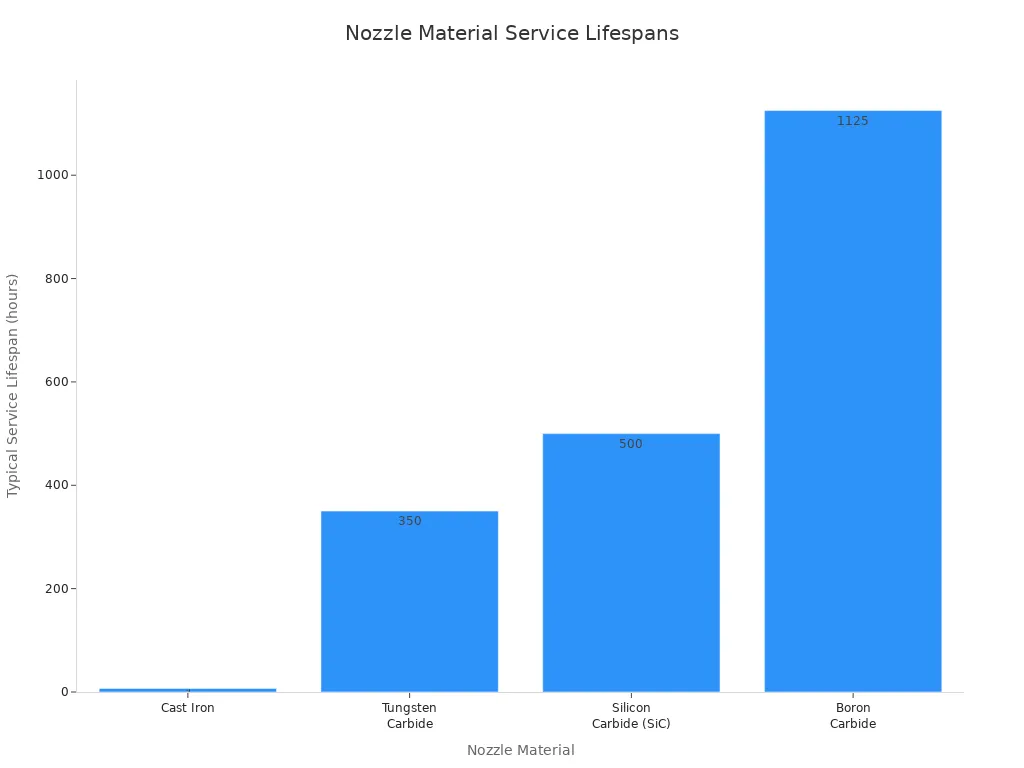

Studies show super-hard materials last much longer than traditional options.

| Nozzle Material | Durability (hours) |

|---|---|

| Ceramic | 1–2 |

| Cast Iron | 6–8 |

| Tungsten Carbide | ~300 |

| Boron Carbide | 750–1000 |

Key Takeaways

- SiC nozzles offer exceptional wear resistance and last much longer than traditional nozzle materials, reducing maintenance and downtime.

- The unique hardness and microstructure of silicon carbide help SiC nozzles resist erosion and cracking during abrasive jet machining.

- Using SiC nozzles improves machining precision and consistency, leading to better quality and cost savings over time.

SiC Nozzles and the Science of Wear Reduction

Causes of Nozzle Wear in Abrasive Jet Machining

Abrasive jet machining exposes nozzles to intense wear. The main reason is the impact of high-velocity abrasive particles on the inner walls of the nozzle. This impact causes material to erode over time. Several factors influence how quickly this wear occurs:

- The geometry of the nozzle, such as the inlet diameter and the length of the focusing tube, changes how particles move and strike the nozzle surface.

- The abrasive flow rate and jet pressure affect how fast and how often particles hit the nozzle.

- Particle size and velocity also play a role in the wear pattern.

Numerical simulations show that particle motion and acceleration inside the nozzle are key factors in wear distribution. When abrasive particles move faster, they strike the nozzle with more force, causing more erosion, especially near the outlet.

| Factor | Effect on Nozzle Wear | Explanation |

|---|---|---|

| Abrasive Mass Flow Rate | Higher flow increases erosion rate inside the nozzle. | More particles mean more frequent impacts and faster wear. |

| Abrasive Diameter | Smaller particles cause higher erosion rates. | Smaller size increases the number of impacts and wear, especially at the nozzle outlet. |

| Jet Velocity | Higher velocity increases erosion at the outlet. | Faster particles hit harder, causing more wear at the exit. |

| Nozzle Wear Impact | Worn outlets change jet velocity and pressure. | This can affect machining quality and increase damage to the workpiece. |

Material Properties of SiC Nozzles That Minimize Wear

SiC Nozzles stand out because of their unique material properties. Silicon carbide has exceptional hardness and chemical stability. These qualities make it highly resistant to erosion from abrasive particles. The microstructure of SiC includes hard, stable particles that resist wear even in harsh environments.

Manufacturers like Ningbo VET Energy Technology Co., Ltd use advanced processes to create SiC nozzles with gradient structures. These structures form compressive residual stresses at the nozzle entry. The compressive stresses help counteract the tensile forces caused by abrasive impacts. This makes the nozzle less likely to crack or wear down quickly.

| Microstructural Characteristic | Effect on Abrasive Performance | Supporting Details |

|---|---|---|

| High hardness and chemical stability | Provides strong wear resistance | SiC particles are hard and stable, ideal for abrasive environments. |

| Gradient structure with compressive stress | Reduces erosion and cracking | Compressive stress at the entry counters impact forces. |

| Uniform microstructure | Improves wear resistance | Promotes milder wear mechanisms and higher microhardness. |

SiC nozzles also benefit from manufacturing techniques that improve their density and toughness. Hot-pressing and careful control of material composition lead to better durability and longer service life.

Comparison of SiC Nozzles with Other Nozzle Materials

Different nozzle materials offer varying levels of wear resistance. The table below compares the hardness and wear resistance of common nozzle materials:

| Material / Composite | Hardness & Wear Resistance Characteristics | Additional Notes |

|---|---|---|

| Silicon Carbide (SiC) | Exceptionally high hardness; excellent wear resistance; suitable for abrasive environments | Lighter than tungsten carbide; chips more easily |

| SiC/(W,Ti)C Gradient Composite | Enhanced mechanical properties and erosion wear resistance beyond common ceramic nozzles | Gradient structure induces compressive residual stresses improving erosion resistance |

| Tungsten Carbide (WC) | Extremely hard; unmatched wear resistance and toughness; resistant to deformation under mechanical stress | Often used in high-pressure abrasive conditions |

| Alumina (Al2O3) | Good thermal stability and chemical resistance; generally less wear resistant than SiC | Cost-effective; used in general-purpose applications |

| Boron Carbide (B4C) | Longest service life; highest erosion resistance | Higher cost but lower cost per hour |

SiC Nozzles typically last longer than tungsten carbide nozzles and offer a lighter alternative. Boron carbide nozzles have the longest lifespan but come at a higher cost. The advanced microstructure and manufacturing methods used by Ningbo VET Energy Technology Co., Ltd ensure that their SiC nozzles deliver reliable performance and extended service life in abrasive jet machining.

Practical Advantages of SiC Nozzles in Machining Operations

Enhanced Lifespan and Reduced Maintenance

SiC Nozzles deliver outstanding wear resistance and hardness, with a Mohs rating near 9.5. This allows them to handle abrasive media like alumina, garnet, or steel grit without rapid degradation. Their long service life means operators replace nozzles less often, which reduces maintenance frequency. Less maintenance leads to fewer interruptions and more machine uptime.

Operators at Ningbo VET Energy Technology Co., Ltd report that SiC Nozzles minimize downtime and keep production lines running smoothly.

Recommended maintenance practices for maximizing nozzle lifespan include:

- Schedule regular inspections based on usage.

- Use precision tools to check for bore wear.

- Clean nozzles with compressed air or soft brushes.

- Document wear patterns and adjust maintenance plans.

- Use clean abrasives and store nozzles in dry conditions.

- Train staff on proper care and follow manufacturer guidelines.

Improved Machining Precision and Consistency

SiC Nozzles maintain tight dimensional tolerances, often as precise as ±0.005 mm. Specialized diamond grinding and lapping ensure accurate orifice sizes and smooth surfaces. This precision helps keep spray patterns and flow rates consistent, even after long periods of use.

The hardness and stability of silicon carbide prevent nozzle geometry from changing, unlike metal or plastic alternatives. Advanced manufacturing controls and post-processing steps further enhance surface finish and geometric accuracy.

Consistent nozzle performance supports high-quality machining results for every job.

Cost Savings and Productivity Gains with SiC Nozzles

Although SiC Nozzles require a higher initial investment, their operational lifespan is five to ten times longer than metallic nozzles. This reduces replacement and maintenance costs over time. Companies like Ningbo VET Energy Technology Co., Ltd benefit from lower total cost of ownership and improved productivity.

Longer nozzle life means fewer workflow interruptions and more predictable production schedules. Integration with automation and real-time monitoring systems further streamlines operations.

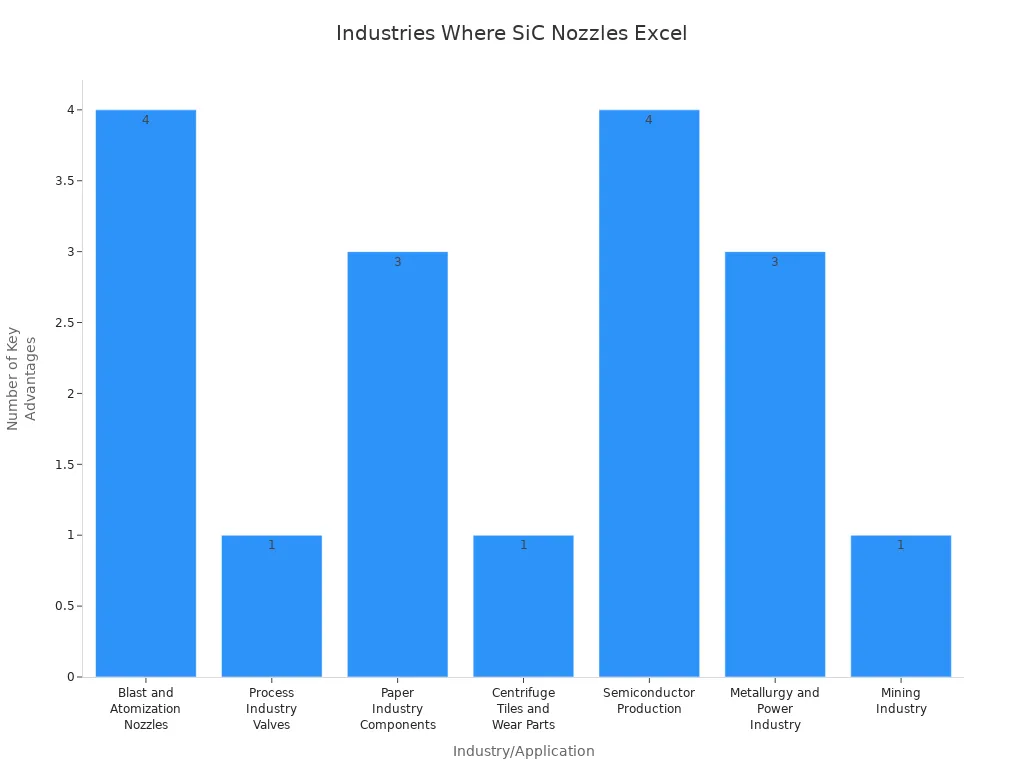

Many industries, including automotive, aerospace, and mining, choose SiC Nozzles for their durability and cost-effectiveness.

SiC Nozzles solve wear issues in abrasive jet machining by delivering unmatched durability and precision. Industry experts note that these nozzles maintain efficiency, reduce downtime, and lower costs.

- SiC Nozzles resist extreme temperatures and corrosion.

- Their lightweight design boosts productivity for operators at Ningbo VET Energy Technology Co., Ltd.

FAQ

What makes SiC nozzles ideal for abrasive jet machining?

Silicon carbide nozzles offer high hardness and excellent wear resistance. They maintain shape and performance longer than most traditional nozzle materials.

How often should operators replace SiC nozzles?

Operators usually replace SiC nozzles after several hundred hours of use. Ningbo VET Energy Technology Co., Ltd recommends regular inspections for optimal performance.

Can SiC nozzles handle different abrasive materials?

Yes. SiC nozzles work well with a wide range of abrasives, including garnet, alumina, and steel grit. Their durability supports many industrial applications.