Ultimate Guide to CVD SiC Coating Solutions for High-Temperature Semiconductor Equipment

CVD SiC Coating Solutions offer thermal resistance, durability, and chemical stability, ensuring reliable performance and extended lifespan for semiconductor equipment.

How to Extend Equipment Lifespan with Advanced CVD SiC Coating in Semiconductor Fabs

Extend semiconductor fab equipment lifespan with advanced CVD SiC Coating. Achieve superior durability, reduced contamination, and long-term cost savings.

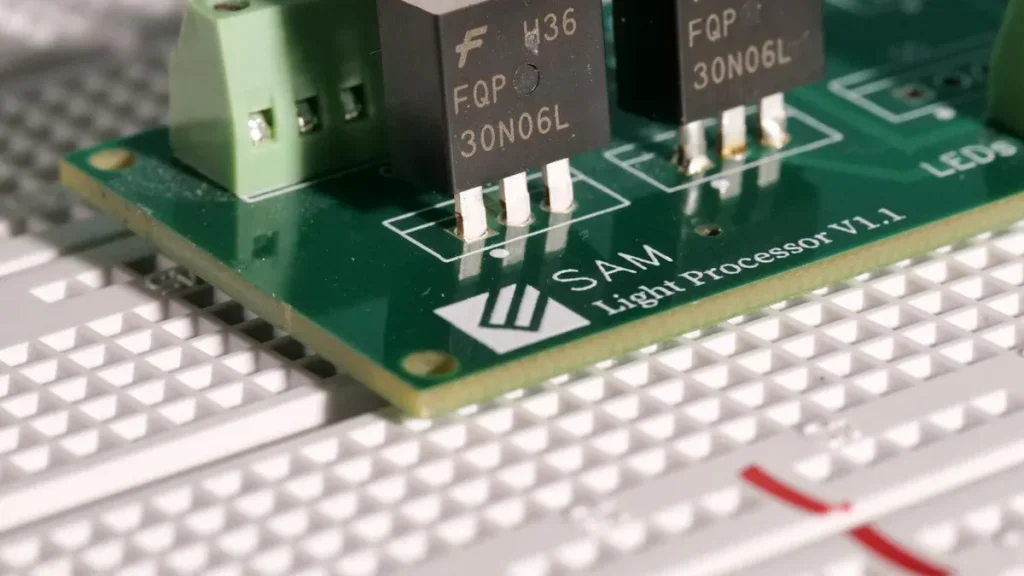

Cost-Effective Graphite Susceptor Designs for High-Volume Metallurgical Furnace Operations

Discover cost-effective graphite susceptor designs that boost furnace efficiency, enhance durability, and ensure uniform heat distribution for high-volume operations.

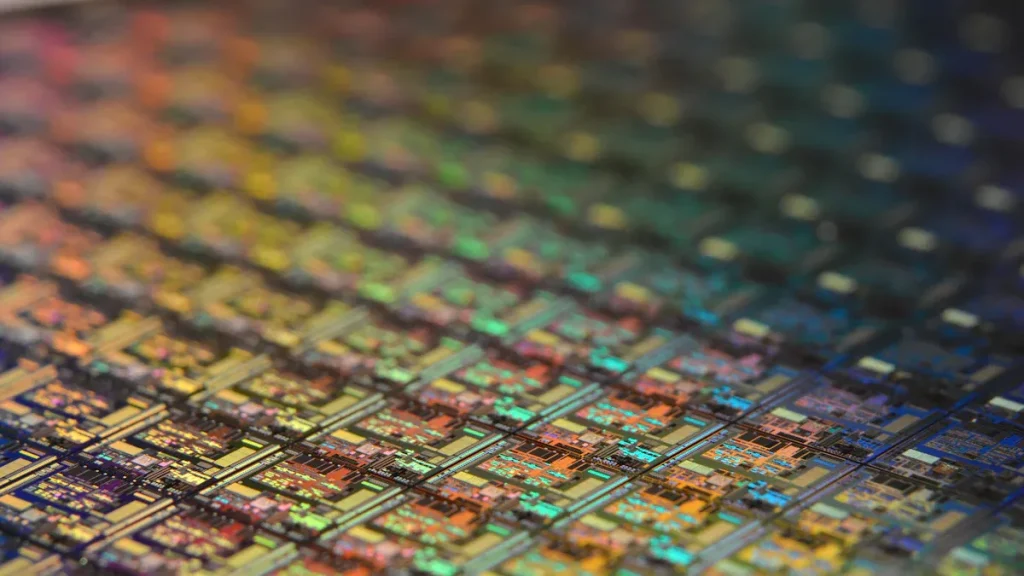

The Role of EPI Susceptors in Improving Epitaxial Growth Efficiency for 5G Chip Production

EPI susceptors improve epitaxial growth efficiency by ensuring uniform heat distribution and material quality, enabling defect-free 5G chip production.

Customized SiC Coating Solutions for OEMs: Meeting Precision Requirements in Aerospace Applications

Customized SiC Coating solutions offer aerospace OEMs unmatched thermal resistance, durability, and precision, ensuring optimal performance in extreme conditions.

Why CVD TAC Coating is Revolutionizing Thermal Management in Photovoltaic Cells

CVD TAC Coating enhances thermal management in photovoltaic cells by improving heat dissipation, preventing hot spots, and extending operational lifespan.

Graphite Susceptor vs. EPI Susceptor: Choosing the Right Wafer Carrier for Your Semiconductor Process

Compare graphite susceptor and EPI susceptor for semiconductor processes. Learn about their thermal performance, cost efficiency, and process compatibility.

Beyond Metallization: Innovative Tic-Tac Coating Techniques for Composite Material Protection

Tic-Tac Coating offers superior durability, lightweight protection, and thermal stability for composites, outperforming traditional metallization techniques.

Preventing Contamination: How Ultra-Dense TaC Coatings Protect Critical Vacuum Chamber Components

Ultra-dense TaC coatings prevent contamination in vacuum systems by reducing gas permeability, ensuring chemical inertness, and withstanding extreme temperatures.

Preventing Contamination: How Ultra-Dense TaC Coatings Protect Critical Vacuum Chamber Components

Ultra-dense TaC coatings prevent contamination in vacuum chambers by reducing outgassing, enhancing durability, and ensuring chemical inertness in critical environments.