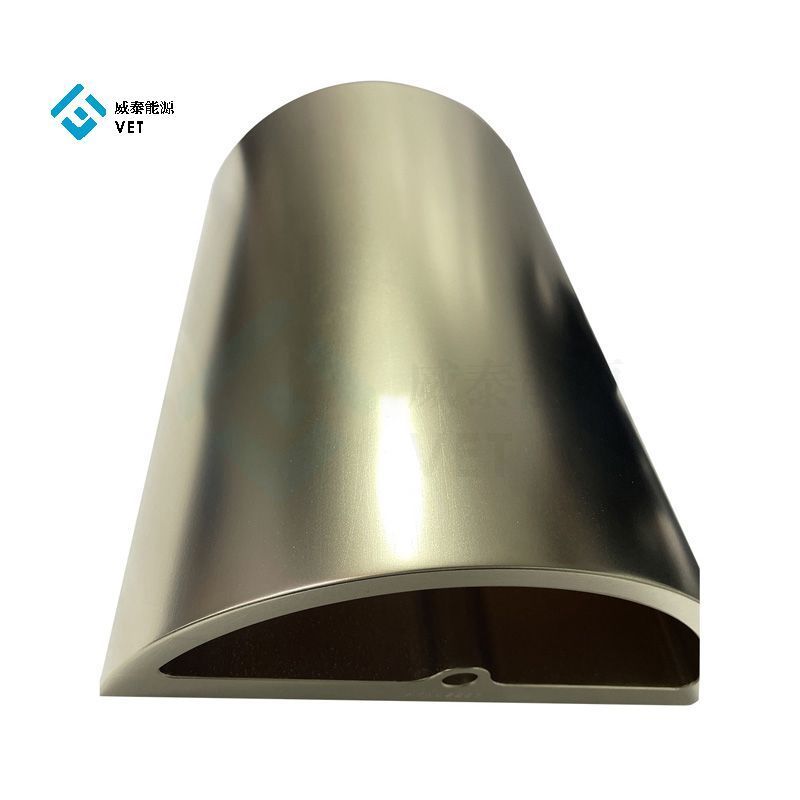

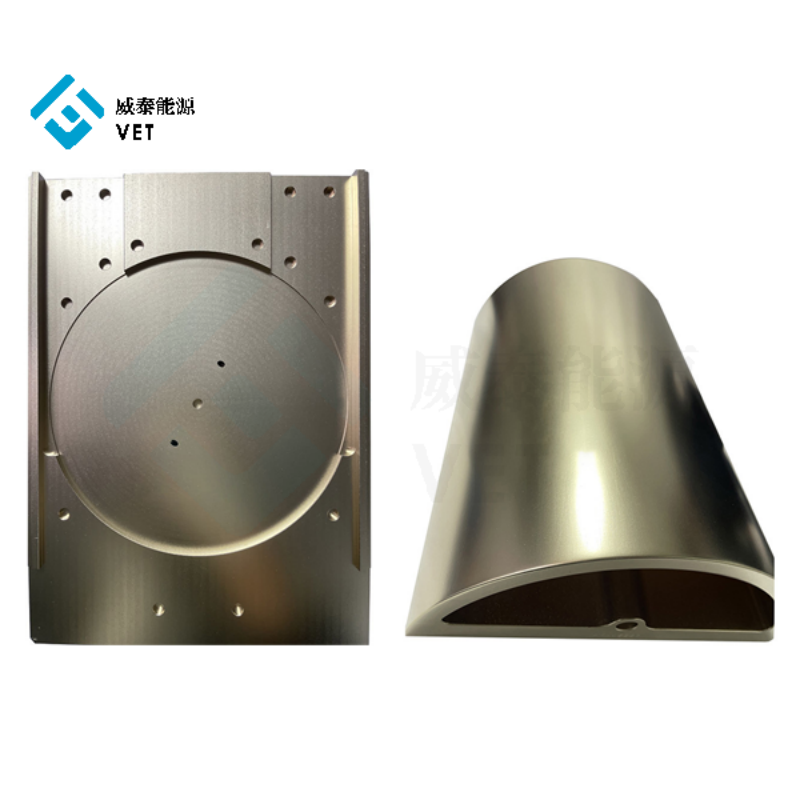

The VET Energy Half-moon part with Tantalum Carbide coating, offering high performance with long-term stable and reliable operation. It boasts excellent heat resistance, thermal uniformity, high purity, and corrosion resistance, making it an ideal choice for wafer processing applications.

TaC coating, made using physical vapor deposition technology, offers:

High hardness (2500-3000HV), making it an excellent hard coating.

Superior wear resistance, reducing mechanical part wear and damage.

Outstanding high-temperature performance.

Excellent chemical stability, resisting reactions with acids and alkalis.

碳化钽涂层物理特性物理特性 TaC涂层的物理性能 | |

密度 / Density | 14.3 (克/立方厘米) |

比辐射率 / Specific emissivity | 0.3 |

热 膨胀系数/ Thermal expansion coefficient | 6.3 10 -6 /K |

努氏硬度 / Hardness (HK) | 2000年香港 |

电阻 / Resistance | 1× 10⁻⁵ 欧姆·厘米 |

热 稳定性/ Thermal stability | <2500℃ |

石墨尺寸变化/ Graphite size changes | -10~-20微米 |

涂层厚度 / Coating thickness | ≥20μm 典型值(35μm±10μm) |

Ningbo VET Energy Technology Co., Ltd. is a high-tech enterprise specializing in the production and sales of advanced materials, including graphite, silicon carbide, ceramics, and surface treatments. Our products are widely used in industries such as photovoltaics, semiconductors, new energy, and metallurgy.

Our technical team, composed of experts from top domestic research institutions, can provide you with professional material solutions.

We warmly welcome you to visit our factory for guidance and further discussions!

Dengan kemampuan R&D dari bahan -bahan utama hingga produk aplikasi akhir, teknologi inti dan utama hak kekayaan intelektual independen telah mencapai sejumlah inovasi ilmiah dan teknologi.