Custom Coating Solutions: Tailoring TaC/SiC Thickness for Specific Thermal Profile Requirements

Tailor SIC COATING thickness for precise thermal profiles, enhancing heat resistance, durability, and efficiency in aerospace, solar energy, and power generation.

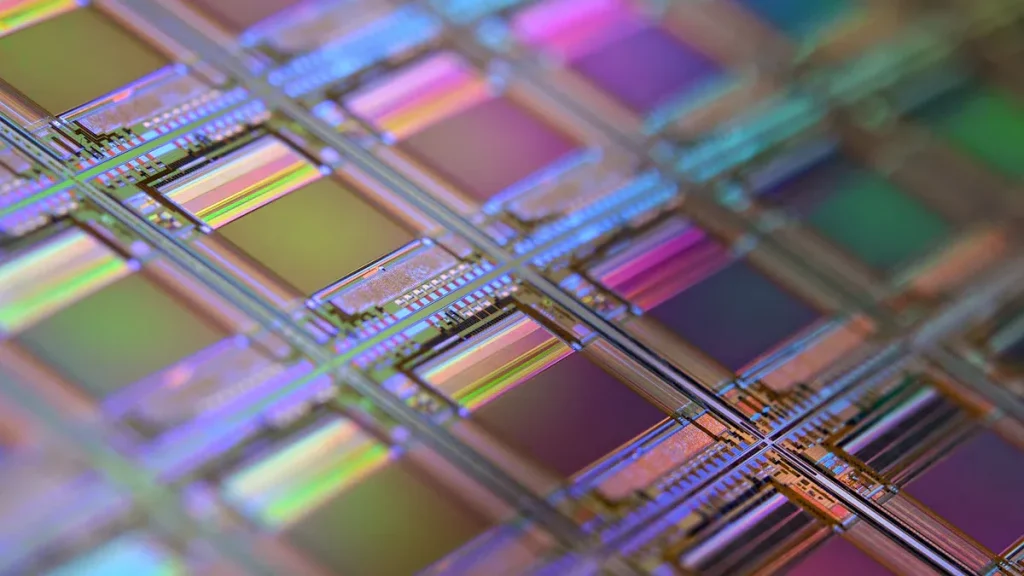

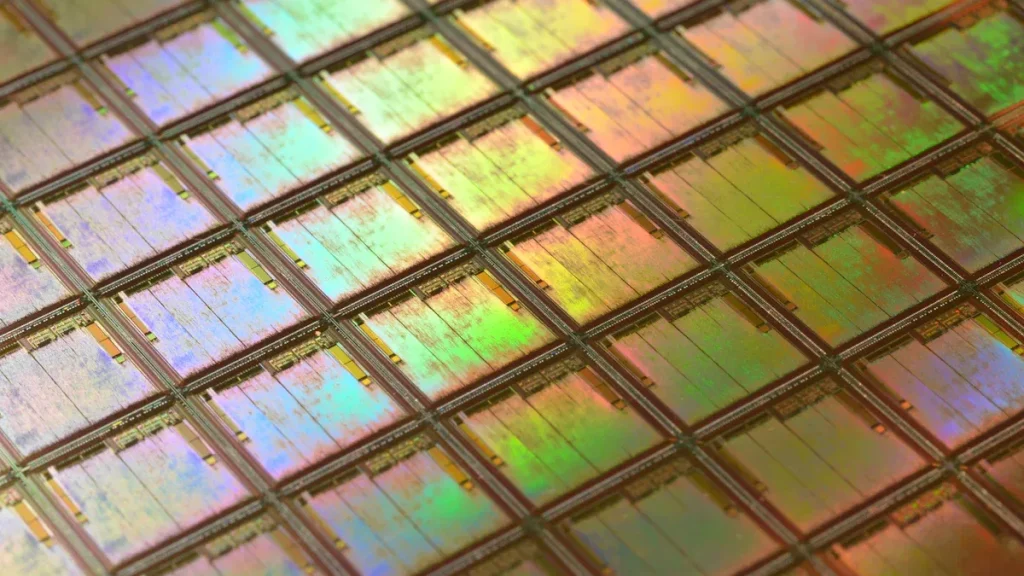

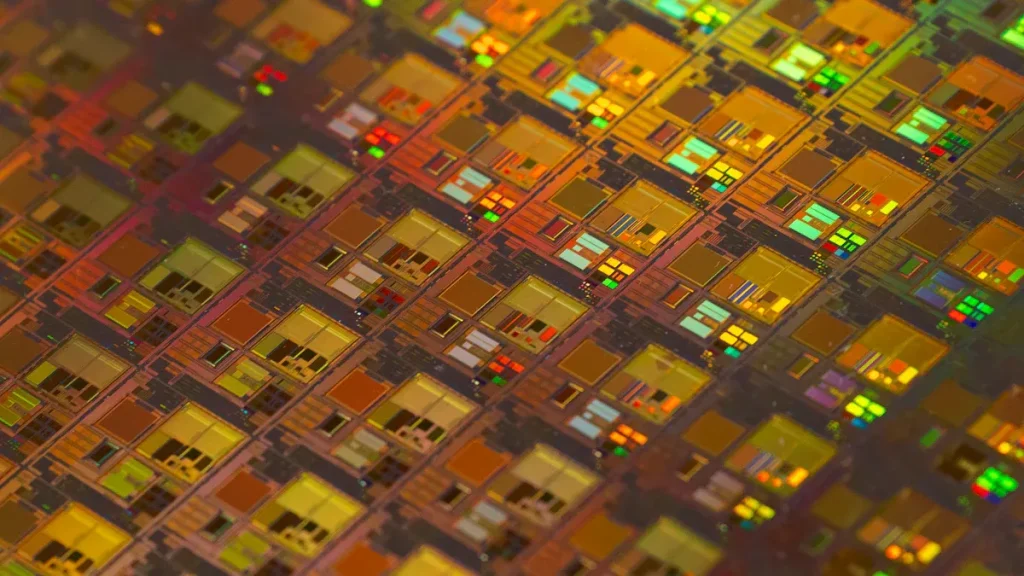

The Role of Advanced Ceramic Coatings in Next-Gen 300mm Silicon Wafer Processing

Advanced ceramic coatings improve 300mm silicon wafer processing by enhancing thermal stability, wear resistance, and contamination prevention for better efficiency.

The Role of Advanced Ceramic Coatings in Next-Gen 300mm Silicon Wafer Processing

Advanced ceramic coatings improve 300mm silicon wafer processing by offering thermal stability, chemical resistance, and wear protection for semiconductor manufacturing.

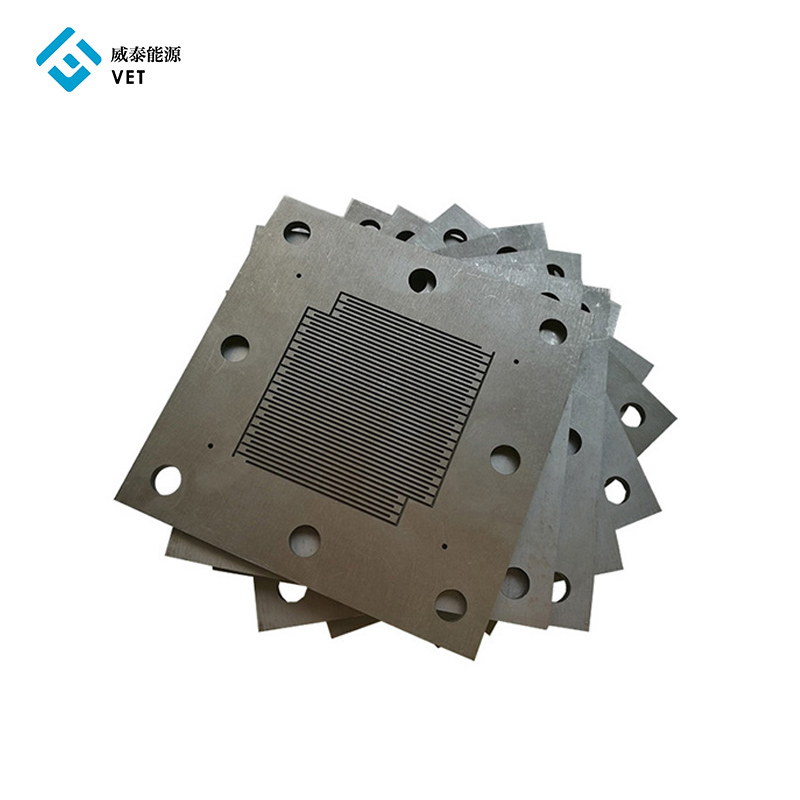

Accelerating Green Energy: CVD-Coated Graphite Plates for Hydrogen Fuel Cell Manufacturing

CVD-coated graphite plates boost hydrogen fuel cell efficiency, durability, and sustainability, making them vital for advancing green energy technologies.

Tantalum Carbide Coating 101: Technical Specifications for Semiconductor OEMs

Tantalum carbide coating offers unmatched hardness, thermal stability, and corrosion resistance, ensuring durability and efficiency for semiconductor OEM tools.

Cost-Benefit Analysis: Investing in Permanent Coatings vs. Replaceable Graphite Parts

Compare the cost, durability, and performance of permanent coatings vs. replaceable graphite parts to determine the best solution for industrial applications.

Why Global Foundries Are Adopting Silicon Carbide Ceramic Coating for Diffusion Process Kits

Global foundries adopt silicon carbide ceramic coating for diffusion kits to enhance durability, thermal resistance, and efficiency, reducing costs and downtime.

Solving Oxidation Challenges: TaC-Coated Graphite Components in Vacuum Furnace Applications

TaC-coated graphite components combat oxidation in vacuum furnaces, enhancing durability, thermal stability, and efficiency in high-temperature applications.

Precision Coating Services: How CVD Technology Extends Graphite Fixture Service Life by 300%

CVD technology enhances graphite fixture durability, extending service life by 300%. Reduce costs, improve reliability, and optimize industrial performance.

The Future of Protective Coatings: Multi-Layer SiC/TaC Hybrid Systems for Extreme Environments

Multi-layer SiC/TaC hybrid systems offer unmatched thermal resistance, durability, and adaptability, making sic coating ideal for extreme environments and industries.