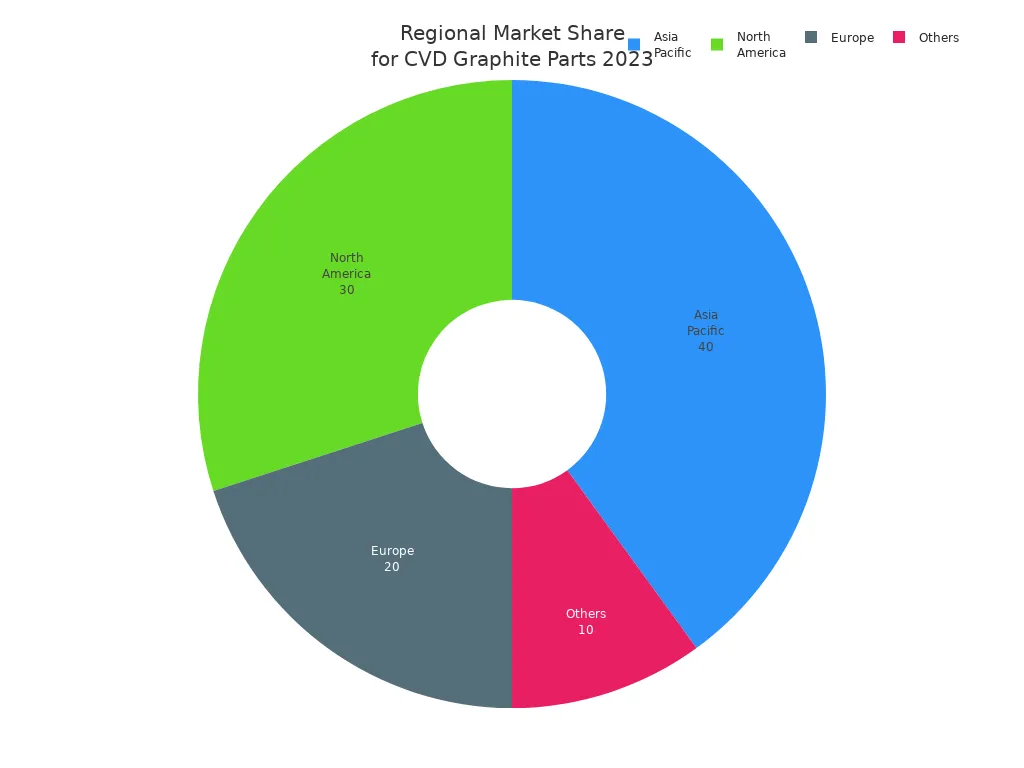

CVD Graphite Parts are essential in high-performance industries such as aerospace, automotive, and electronics. Manufacturers in these sectors depend on high-purity graphite components そして carbon-based susceptors for their superior reliability under extreme heat conditions. The Asia Pacific region dominates the global market for CVD Graphite Parts, as illustrated below:

グラファイトの感受性 and carbon-based susceptor technologies continue to drive innovation in advanced applications around the world.

要点

- CVD Graphite Parts withstand extremely high temperatures up to 3000°C, maintaining strength and shape where most materials fail.

- 炭化ケイ素のコーティング protect graphite parts from corrosion and thermal shock, extending their life in harsh industrial environments.

- These parts are vital in aerospace, semiconductor, and energy industries for reliable, cost-effective performance under extreme heat.

Unique Properties of CVD Graphite Parts in High-Temperature Applications

熱安定性と耐熱性

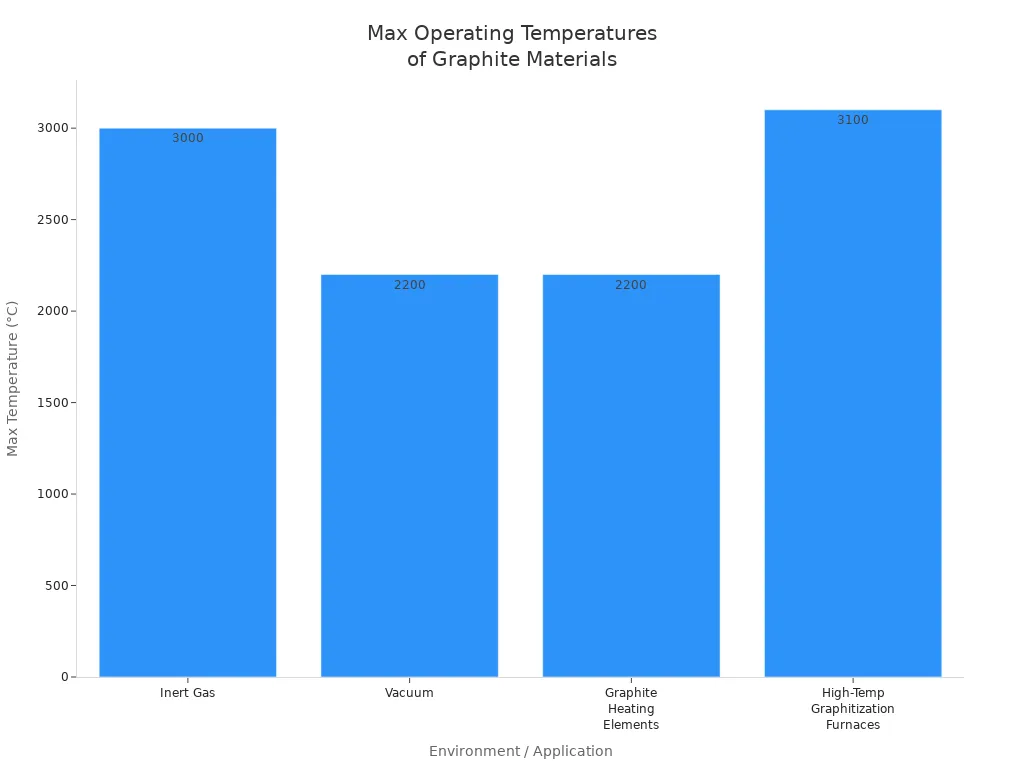

CVD Graphite Parts deliver outstanding thermal stability, making them essential for environments where temperatures soar beyond the limits of most materials. These parts maintain their structure and function even when exposed to temperatures up to 3000°C in inert gas and 2200°C in vacuum. This performance far exceeds that of most ceramics and metals, which often degrade or deform at lower temperatures. The following table highlights the maximum operating temperatures for graphite parts in different environments:

| Environment | 最高の実用温度 | Notes / Applications |

|---|---|---|

| Inert Gas | Up to 3000°C | Suitable for high-temperature furnaces and synthesis |

| Vacuum | Up to 2200°C | Used in aerospace, electronics, semiconductor manufacturing |

| Graphite Heating Elements | Max 2200°C, Service 2100°C | Industrial heating, sintering furnaces |

| High-Temperature Graphitization Furnaces | Up to 3100°C | Specialized furnaces for graphitization processes |

Laboratory and field tests confirm this stability. For example, ultra-high temperature graphitization furnaces and graphite vacuum heat treat furnaces operate at these extreme temperatures, demonstrating the reliability of CVD Graphite Parts under sustained heat. These parts do not lose their shape or mechanical strength, even after repeated exposure to intense thermal cycles.

Ceramic crucibles, such as those made from high-purity alumina, can withstand up to 1800°C for short periods. However, CVD Graphite Parts offer superior thermal conductivity and corrosion resistance, making them more efficient for rapid heat transfer and energy management. Metals, by comparison, generally have lower maximum operating temperatures and may deform or melt under similar conditions.

Thermal Conductivity and Low Expansion

CVD Graphite Parts excel in thermal conductivity, allowing heat to move quickly and evenly through the material. This property ensures efficient energy use and reduces the risk of hot spots that could damage equipment. At the same time, these parts have a low coefficient of thermal expansion. They expand very little when heated, which minimizes mechanical stress and prevents cracking or warping.

注: Low thermal expansion is crucial for precision components. It ensures that parts retain their exact dimensions, even during rapid temperature changes.

- CVD Graphite Parts expand less than most other high-temperature materials.

- This stability makes them ideal for semiconductor manufacturing, aerospace, and other industries where accuracy matters.

- The combination of high thermal conductivity and low expansion improves durability and extends service life.

化学安定性および酸化抵抗

CVD Graphite Parts resist chemical attack in harsh environments. Manufacturers often apply 炭化ケイ素(SiC)のコーティング to further enhance this resistance. Tests show that SiC-coated graphite parts withstand exposure to corrosive gases like chlorine (Cl2) and ammonia (NH3) at high temperatures. These coatings protect the graphite from mass loss, surface roughness changes, and crack formation.

- SiC coatings provide exceptional resistance to corrosion in semiconductor growth environments.

- Thermal cycling and fatigue resistance tests confirm the durability of these coatings.

- Oxidation resistance tests at temperatures up to 1600°C demonstrate that CVD Graphite Parts maintain their integrity, even in oxidative atmospheres.

This chemical stability makes CVD Graphite Parts suitable for use in aggressive industrial processes, including those involving acids, alkalis, and reactive gases.

耐熱衝撃性

Thermal shock occurs when materials experience rapid temperature changes, which can cause cracking or failure. CVD Graphite Parts, especially those with silicon carbide coatings, show outstanding resistance to thermal shock. Their high thermal conductivity and low thermal expansion allow them to absorb and dissipate heat quickly, reducing the risk of damage.

- Silicon carbide-coated graphite parts outperform many other refractory materials during rapid heating and cooling cycles.

- These properties make them reliable for applications such as high-temperature furnaces, aerospace components, and semiconductor processing.

ヒント For environments with frequent temperature fluctuations, CVD Graphite Parts offer a dependable solution that minimizes downtime and maintenance costs.

CVD Graphite Parts in Real-World Applications and Performance Advantages

Aerospace and Defense Uses

Aerospace and defense industries demand materials that can withstand extreme heat, rapid temperature changes, and corrosive environments. CVD Graphite Parts meet these requirements by providing high thermal stability and resistance to oxidation. Engineers use these parts in rocket nozzle liners, heat shields, and thermal protection systems. The lightweight nature of graphite, combined with its ability to maintain structural integrity at temperatures above 2000°C, makes it ideal for critical aerospace components. The silicon carbide coating further enhances durability, allowing these parts to perform reliably during repeated launch and re-entry cycles. Defense systems also benefit from the material’s resistance to thermal shock and mechanical wear, ensuring mission success in harsh conditions.

半導体・電子製造

Semiconductor and electronics manufacturing relies on precise temperature control and chemical stability. Graphite used in these processes exhibits melting points above 3600°C, maintaining structural stability during extreme heat. Its excellent thermal conductivity ensures uniform surface temperature, which is essential for consistent film quality during chemical vapor deposition. Manufacturers fabricate graphite into susceptors, wafer boats, and chamber liners, all of which play a vital role in supporting wafer processing and film deposition at temperatures often exceeding 1000°C.

- SiC coatings must fully cover グラファイトの感受性 with high density to prevent corrosion in corrosive gas environments.

- The coating bonds strongly to graphite, enduring multiple high-temperature cycles without peeling.

- SiC provides chemical stability, resisting failure in high-temperature, corrosive atmospheres typical of semiconductor fabrication.

- The thermal expansion compatibility between SiC and graphite minimizes stress and maintains coating integrity.

- CVD is the primary method to deposit SiC coatings, producing tightly bonded layers that enhance oxidation and ablation resistance, critical for extreme heat resistance in semiconductor manufacturing.

CVD Graphite Parts maintain dimensional stability and mechanical strength under rapid thermal cycling and plasma bombardment. This ensures process uniformity and extends equipment lifespan, reducing downtime and maintenance costs.

Energy Production and High-Temperature Furnaces

Energy production and advanced manufacturing require materials that can operate in high-temperature furnaces and reactors. Graphite vacuum furnaces reach temperatures up to 2200°C and support vacuum sintering of materials. Large vertical graphitization furnaces operate at temperatures up to 3100°C for the graphitization of carbon materials. Ultra-high temperature graphite vacuum furnaces use induction heating in vacuum or inert gas for sintering and graphitization. Specialized graphite furnaces are essential in battery production, providing uniform temperature and low energy consumption for the graphitization of negative electrode materials.

A case study describes the synthesis of pyrolytic graphite coatings on high-density graphite substrates via chemical vapor deposition at temperatures up to 2200°C. These coatings show high thermal stability and oxidation resistance, making them suitable for use in pyrochemical reprocessing of nuclear fuels. The graphite parts serve as crucibles and liners in processes involving corrosive molten salts for uranium and plutonium recovery, highlighting their critical role in energy production applications.

- Graphite components in CVD reactors withstand extremely high temperatures and corrosive chemicals, ensuring long-term durability and stable performance.

- CVD furnaces improve energy efficiency and extend the lifespan of energy systems by advancing coatings for batteries, fuel cells, and solar panels.

- Precise temperature regulation maintains ideal heating zones, ensuring uniform coating quality and consistent substrate performance.

- High-quality graphite parts provide excellent longevity under harsh conditions, reducing maintenance and downtime.

Longevity, Cost-Effectiveness, and Versatility

CVD Graphite Parts offer significant advantages in longevity and cost-effectiveness. The combination of graphite’s lightweight structure and high thermal conductivity allows for efficient heat transfer and ease of fabrication into complex shapes. SiC coated graphite parts exhibit superior mechanical properties, such as enhanced surface hardness and wear resistance, making them durable in abrasive and moving contact environments.

- Customizable coating thickness, surface finish, and shape enable adaptation to specific industrial needs.

- SiCコーティンググラファイト is widely used across various high-temperature industries, including semiconductor manufacturing, thermal processing, chemical industry, aerospace, and new energy sectors.

- The SiC coating provides excellent corrosion resistance against acids, alkalis, and aggressive gases, outperforming metals and uncoated ceramics.

- The coating acts as an oxidation barrier, enabling use in oxidative and thermal cycling environments without degradation.

- Cost-efficiency is achieved through longer part lifetimes, reduced maintenance, and minimized contamination risks.

These features support broad industrial applicability and reliability, making CVD Graphite Parts a preferred choice for demanding applications.

Challenges, Limitations, and Mitigation Strategies

Despite their many advantages, CVD Graphite Parts face several challenges in extreme heat conditions:

- High processing temperatures during CVD require substrates that can withstand 800°C to 1000°C, increasing cost and complexity.

- Thick CVD coatings can develop tensile stress during cooling, causing fine cracks and potential peeling.

- Removing deposited layers from substrates without damage is difficult, sometimes involving harmful chemicals.

- Chemical separation techniques can introduce impurities or structural damage, compromising performance.

- The need for high-temperature-resistant substrates restricts material options.

- Hazardous chemicals used in processing raise safety and environmental concerns.

To address these challenges, engineers have developed several mitigation strategies:

- Use sacrificial layers to protect graphite parts from oxidation and wear, extending service life.

- Operate graphite parts within inert atmospheres to minimize oxidative degradation.

- Apply oxidation-resistant coatings to enhance protection.

- Utilize specialized furnace designs that maintain controlled environments, such as vacuum graphitization furnaces, to further reduce graphite degradation.

ヒント These strategies collectively enhance the durability and performance of CVD Graphite Parts, ensuring their continued reliability in high-temperature environments.

CVD Graphite Parts deliver unmatched performance in extreme heat.

- Industry experts report tool life improvements of up to 15 times and cost reductions of 40% to 80%.

- Protective coatings and smart machining strategies extend service life.

| 特徴 | ベネフィット |

|---|---|

| 高い熱伝導性 | Reliable in high-temperature industries |

よくあるご質問

What industries benefit most from CVD graphite parts?

Aerospace, semiconductor, energy, and chemical industries use CVD graphite parts. These sectors require materials that withstand high temperatures and harsh environments.

How do SiC coatings improve graphite part performance?

Silicon carbide (SiC) coatings protect graphite from oxidation and corrosion. These coatings extend part life and maintain strength during repeated heating cycles.

Can CVD graphite parts be customized for specific applications?

Manufacturers can produce CVD graphite parts in various shapes and sizes. Customization ensures each part meets unique requirements for different high-temperature processes.