セラミックコーティング use advanced nanotechnology to form a dense, invisible layer that bonds tightly to car paint. Scientific research shows that this shield, similar to thermal barrier coatings, CVD SiCの層, 炭化ケイ素コーティングそして SiCコーティング, delivers strong resistance to water, UV rays, and chemicals, helping vehicles maintain a glossy, protected finish for years.

要点

- セラミックコーティング form a strong, long-lasting shield that protects car paint from water, UV rays, chemicals, and scratches by bonding tightly at the molecular level.

- Nanoparticles in ceramic coatings create a smooth, hydrophobic surface that repels water and dirt, making cars easier to clean and keeping the paint shiny for years.

- Proper surface preparation, professional application, and gentle maintenance are essential to maximize the coating’s durability and protective power.

Ceramic Coatings: What They Are

Composition and Structure

Ceramic coatings use advanced chemistry to protect vehicle paint. The main ingredients include silicon dioxide (SiO₂), titanium dioxide (TiO₂), and polysiloxanes. Silicon dioxide forms the backbone of the coating, giving it strength and resistance to scratches. Titanium dioxide adds extra protection against ultraviolet (UV) rays and helps keep the paint looking shiny and bright. Polysiloxanes act as binders, making sure the coating sticks tightly to the car’s surface and lasts for years. During application, solvents help spread the coating evenly, but these evaporate as the coating cures, leaving behind a solid, clear shield. This structure creates a tough, hydrophobic layer that keeps water, dirt, and chemicals from damaging the paint.

Note: The combination of these ingredients allows ceramic coatings to deliver long-lasting protection and a glossy finish that highlights the car’s original color.

Differences from Waxes and Sealants

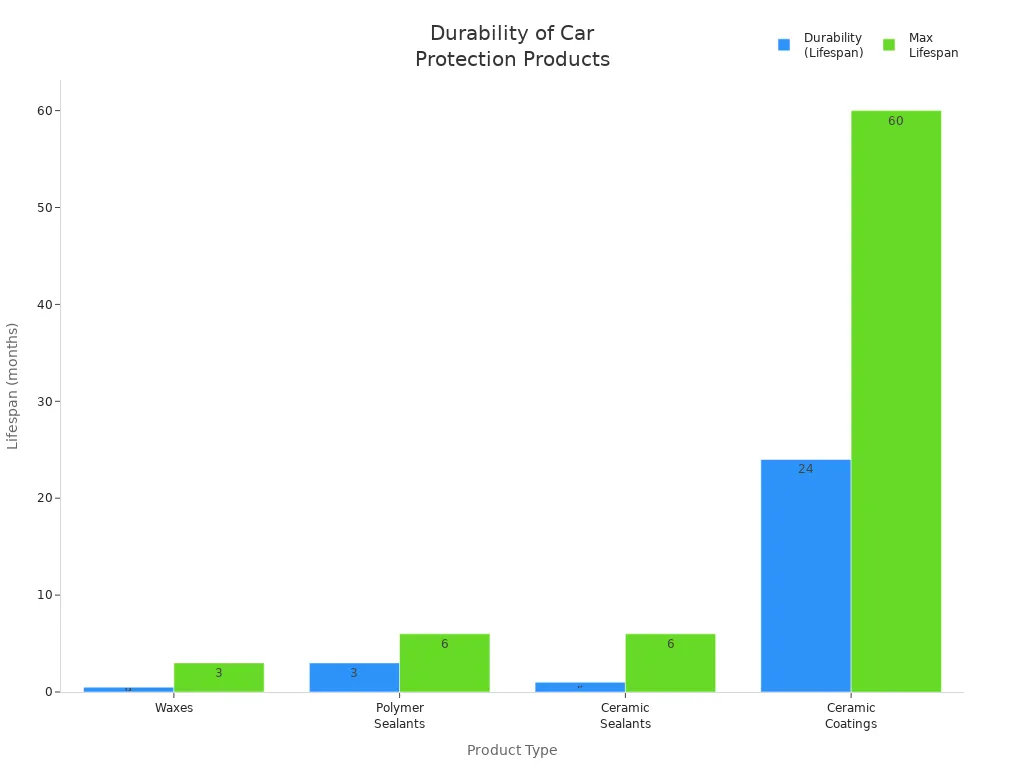

Ceramic coatings stand apart from waxes and sealants because of their unique molecular structure and bonding strength. Waxes use large molecules that sit on top of the paint and bond weakly, so they wash away easily. Sealants use synthetic polymers with medium-sized molecules that form a semi-permanent net over the paint. In contrast, ceramic coatings use nano-sized particles that form strong chemical bonds with the surface, creating a much harder and more durable layer.

| 特徴 | Wax | Sealants | セラミックコーティング |

|---|---|---|---|

| 寿命 | 1-3 months | Up to 6 months | Several years |

| Protection Level | Basic | 中程度 | アドバンスト |

| UV Protection | Limited | Shields paint | Superior protection |

| Hydrophobicity | 低い | 中程度 | Extreme |

| コスト | Low ($) | Moderate ($$) | High ($$$) |

| 応用消去 | 簡単 | 中程度 | Professional required |

Ceramic coatings last much longer than waxes or sealants. They provide stronger protection against chemicals, UV rays, and water. While waxes and sealants need frequent reapplication, ceramic coatings can protect a car for several years with proper care.

Nanotechnology in Ceramic Coatings

How Nanoparticles Protect Paint

Nanotechnology gives ceramic coatings their unique protective power. Scientists design these coatings with nanoparticles that measure less than 100 nanometers. These tiny particles, mainly silicon dioxide (SiO₂) and titanium dioxide (TiO₂), fit into the smallest pores and imperfections on a car’s paint. Their small size allows them to cover the surface evenly and form a strong, glass-like shield.

| Nanoparticle Type | Function in Ceramic Coating |

|---|---|

| Silicon dioxide (SiO₂) | Improves hardness and scratch resistance; forms a durable, high-gloss finish. |

| Titanium dioxide (TiO₂) | Provides UV protection and enhances weather resistance. |

| Graphene oxide | Enhances mechanical strength, used in specialized coatings. |

| Bonding Process | Nanoparticles chemically bond with paint during curing, hardening the surface. |

| Hydrophobic Effect | Creates a water-resistant layer, causing water to bead and roll off for self-cleaning. |

Nanoparticles fill every tiny gap in the paint, creating a smooth surface that dirt and water cannot easily stick to. This hydrophobic effect causes water to bead up and roll off, taking dust and grime with it. The coating also blocks harmful UV rays, which helps prevent fading and oxidation. The result is a surface that stays cleaner and looks shinier for longer.

Tip: The nanoscale size of these particles means the coating can form a thin, hard layer—just 1 to 3 microns thick—that protects without changing the look of the paint.

Chemical Bonding at the Molecular Level

The real strength of ceramic coatings comes from the way nanoparticles bond with the paint. When applied, the coating’s nanoparticles chemically attach to the clear coat of the vehicle. This process forms a cross-linked matrix, which acts as a tough shield against scratches, chemicals, and weather.

- セラミックコーティング contain silicon dioxide and titanium dioxide nanoparticles that bond with the paint at the molecular level.

- These nanoparticles create covalent bonds, forming a seamless network that becomes part of the paint surface.

- The coating fills microscopic pores, resulting in a smooth, mirror-like finish.

- This molecular bonding gives the coating a hardness rating of up to 9H, making it highly resistant to scratches and environmental damage.

- The nanostructure repels water, oils, and contaminants, which helps keep the paint clean and glossy.

- Titanium dioxide nanoparticles absorb UV radiation, protecting the paint from fading and oxidation.

- The cured coating becomes an integral part of the paint, offering long-lasting protection that outperforms waxes and sealants.

The chemical bond ensures the coating does not simply sit on top of the paint. Instead, it becomes a unified layer that resists washing, minor scratches, and harsh chemicals. This advanced technology keeps vehicles looking newer for longer and reduces the need for frequent detailing.

Protective Science of Ceramic Coatings

Hydrophobic and Self-Cleaning Effects

Ceramic coatings create a surface that repels water and dirt. Scientists measure this effect by looking at the water contact angle. When a water droplet lands on a coated car, it forms a bead instead of spreading out. Laboratory tests show that these contact angles usually range from 91 to 120 degrees. A higher angle means stronger water repellency. This property helps water roll off the paint, carrying away dust and grime.

The self-cleaning effect comes from the coating’s nanostructure. Tiny particles fill in the smallest gaps on the paint, making the surface very smooth. Water cannot stick to this surface, so it beads up and slides off easily. As water moves, it picks up dirt and other contaminants. This process keeps the car cleaner for longer and reduces the need for frequent washing.

Professional ceramic coatings can keep their self-cleaning power for years, even after hundreds of washes. The hydrophobic layer stays strong, making it hard for water spots and stains to form.

Car owners often check the coating’s performance by spraying water on the car and watching how it behaves. If the water beads up and rolls off, the coating is still working well. This simple test helps people see if the surface remains protected.

UV and Chemical Resistance

Ceramic coatings act as a shield against harmful ultraviolet (UV) rays. UV radiation can break down car paint, causing it to fade and lose its shine. The coating blocks much of this radiation, slowing down the fading process. Studies show that cars with ceramic coatings have up to 30% less color loss in one year compared to cars without protection. This helps keep the paint looking new and bright for a longer time.

The coating also protects against chemical stains. It forms a hard, water-repellent barrier that resists both acidic and alkaline substances. This means the surface can withstand things like bird droppings, tree sap, road salt, and even harsh cleaners. The coating’s chemical structure allows it to handle a wide pH range, from 2 to 12, without breaking down. As a result, the car’s paint stays safe from many common sources of damage.

The hydrophobic effect not only keeps water away but also stops chemicals from sticking to the paint. This makes cleaning easier and helps prevent stains and etching.

Surface Hardness and Scratch Defense

Ceramic coatings provide a tough, glass-like layer over the car’s paint. Scientists use the pencil hardness test to measure this strength. Most coatings reach a 9H rating, which means they resist scratches from very hard pencils. The main ingredient, nano silica, creates a layer similar to quartz, which has a Mohs hardness of about 7. This makes the surface much harder than untreated paint.

- The coating helps prevent light scratches, such as swirl marks from washing or minor contact with soft materials.

- The smooth surface reduces the chance of dirt and grit sticking to the paint, lowering the risk of scratches from contaminants.

- The hydrophobic layer also helps by letting dirt slide off more easily.

However, ceramic coatings are not scratch-proof. They cannot stop deep scratches caused by sharp objects or heavy impacts. The layer is thin, usually around 6-7 microns, so it cannot protect against all types of damage. Proper washing methods, like using microfiber towels and the two-bucket method, help maintain the coating’s protective power.

For the best protection against deep scratches, experts recommend using paint protection film along with ceramic coatings.

Benefits of Ceramic Coatings for Car Owners

Long-Term Paint Protection

セラミックコーティング deliver reliable, long-lasting protection for vehicle paint. Professional-grade coatings often last up to two years or more, while some brands report durability of up to five years with proper care. Environmental factors and regular maintenance play a role in how long the protection lasts. Unlike waxes that require frequent reapplication, ceramic coatings form a strong bond with the paint, shielding it from UV rays, chemicals, and daily wear.

Enhanced Gloss and Shine

Drivers notice a deep, mirror-like shine after applying ceramic coatings. This glossy finish comes from the chemical bond between the coating and the paint. The result is a wet-look appearance that lasts for years, not just weeks. Unlike wax, which fades quickly, ceramic coatings maintain their shine by resisting UV damage and repelling dirt. The surface stays bright and reflective, even with minimal upkeep.

Easier Cleaning and Maintenance

Ceramic coatings create a slick, hydrophobic surface that repels water and dirt. Owners find that washing becomes much easier, as most grime rinses away with little effort. The coating reduces the need for frequent washing and eliminates the hassle of regular waxing. Many users report that a simple rinse restores the car’s shine, saving both time and water.

長期的な費用対効果

Although ceramic coatings require a higher initial investment, they offer significant savings over several years. The table below compares the costs and maintenance needs of ceramic coatings and traditional wax:

| アスペクト | Ceramic Coating | Traditional Wax |

|---|---|---|

| Initial Cost | $500–$2,000 | $20–$100 per application |

| 長寿 | 2–5 years | 2–4 months |

| Maintenance Effort | 低い | 高い |

| Long-term Cost Impact | ダウンロー | ハイアー |

Over a five-year period, ceramic coatings reduce the need for frequent reapplications and maintenance, making them a smart choice for long-term vehicle care.

Ceramic Coatings Application Process

Surface Preparation

Proper surface preparation ensures the coating bonds well and lasts longer. Technicians follow a series of steps to create a clean, smooth foundation:

- Rinse the vehicle and wash it with a pH-neutral soap using the two-bucket method. This removes loose dirt and grime.

- Apply an iron remover to dissolve embedded metal particles that could cause rust.

- Use a clay bar or clay mitt with lubricant to lift stubborn contaminants like tar, sap, and road film.

- Inspect the paint by touch. If rough spots remain, repeat the claying process.

- Perform paint correction with a dual-action polisher and compounds to eliminate scratches, swirls, and oxidation.

- Clean the surface with isopropyl alcohol or a dedicated cleanser to remove oils and residues.

- Tape off rubber trims and plastics to prevent accidental coating.

These steps enhance adhesion, improve the finish, and prevent future damage by removing substances that could corrode the paint if trapped underneath.

Applying the Coating

Application requires careful technique and attention to detail. Professionals work in a controlled environment to avoid dust and moisture. They use high-quality applicators to spread the product evenly over small sections. Each area receives a thin, uniform layer. After a short wait, they buff the surface with a microfiber towel to remove excess and prevent streaks or high spots. Good lighting helps spot any missed areas or uneven coverage. Skipping steps or rushing can lead to blotchy finishes, weak protection, or residue that is hard to remove.

Curing and Initial Care

Curing allows the coating to harden and reach full strength. Most coatings need 7 to 14 days to cure completely. During this time, the vehicle should stay away from water, dust, and direct sunlight. Ideal curing conditions include temperatures between 50°F and 86°F and humidity below 70%. Exposure to moisture or contaminants during curing can dull the finish and reduce protection. Following manufacturer guidelines ensures the coating forms a strong, glossy, and hydrophobic layer. After curing, maintenance becomes easier, and the vehicle enjoys long-lasting shine and defense.

セラミックコーティングのメンテナンスのヒント

Regular Washing Guidelines

Proper washing keeps the coating strong and the vehicle looking its best. Experts recommend washing every two weeks with a pH-neutral car shampoo. These shampoos clean without harming the protective layer. Soft microfiber wash mitts and towels help prevent scratches during cleaning and drying. The two-bucket method works well to keep dirt from returning to the paint. One bucket holds clean soapy water, while the other holds rinse water for the mitt.

- Wash the car by hand using pH-neutral or ceramic-specific shampoos.

- Use microfiber mitts and towels for both washing and drying.

- Avoid automatic car washes with spinning brushes, as they can scratch the surface.

- Perform chemical decontamination with iron and tar removers two to three times a year.

- Apply ceramic coating boosters every few months to restore water beading and shine.

- Park in a garage or use a car cover to protect from UV rays and contaminants.

Tip: Manual cleaning with gentle products helps maintain the coating’s hydrophobic effect and gloss.

What to Avoid After Application

Certain actions can weaken or damage the coating, especially right after application. Owners should avoid washing the car too soon, as the coating needs time to bond. Harsh chemicals, abrasive cleaners, and products with strong solvents can strip the protective layer. Parking under trees exposes the car to bird droppings and sap, which can etch the surface. Automatic car washes with brushes may scratch or dull the finish.

- Do not use dish soap or generic cleaners.

- Avoid applying waxes or sealants over the coating.

- Steer clear of harsh detergents and acidic wheel cleaners.

- Protect the car from direct sunlight and extreme heat when possible.

- Dry with soft microfiber towels, patting instead of rubbing.

Regular inspections and prompt cleaning of contaminants help preserve the coating’s performance.

Advancements in nanotechnology have transformed vehicle protection. Professional detailers and fleet operators report longer-lasting shine, easier cleaning, and reduced maintenance costs.

Real-world data shows these coatings withstand harsh climates, resist pollution, and help vehicles retain higher resale value. Choosing this technology means less worry and more time enjoying a brilliant finish.

よくあるご質問

How long does a ceramic coating last?

Most ceramic coatings protect paint for two to five years. Longevity depends on product quality, application, and regular maintenance.

Can ceramic coatings prevent all scratches?

Ceramic coatings resist light scratches and swirl marks. They do not stop deep scratches from sharp objects or accidents.

Is professional application necessary?

Professional application ensures even coverage and maximum durability. Some DIY kits exist, but experts achieve better results and longer-lasting protection.