عناصر تسخين كربيد السيليكون (SIC) ، والمعروفة أيضًا باسم عنصر التدفئة كذا، هي ضرورية في قيادة التطورات في إنتاج الهيدروجين الأخضر. قدرتهم على العمل في درجات الحرارة القصوى ، والوصول إلى ما يصل إلى 1850 درجة مئوية (3،362 درجة فهرنهايت)، يضمن الكفاءة المثلى في عمليات درجات الحرارة العالية مثل التحليل الكهربائي. معززة مع المتطورة التنسيق التكنولوجيا ، هذه العناصر تقلل من العيوب السطحية ، وتحقيق مستويات خشونة ملحوظة تصل إلى 0.8 نانومتر RMS. هذه الاختراقات هي إحداث ثورة في حلول الطاقة المستدامة ، مع شركة Ningbo Vet Energy Technology Co. ، Ltd في طليعة الابتكار.

المداخل الرئيسية

- تعمل عناصر التدفئة SIC بشكل جيد في حرارة عالية جدًا ، مما يجعلها رائعة لإنشاء الهيدروجين الأخضر مع التحليل الكهربائي.

- تستخدم عناصر التدفئة هذه طاقة أقل ، وخفض التكاليف بما يصل إلى 30% ومساعدة العملية على البقاء مراعية للبيئة.

- عناصر التدفئة كذا مواد كيميائية قوية ومقاومة، لذلك يحتاجون إلى إصلاح أقل والعمل بشكل موثوق في إعدادات المصنع الصعبة.

إنتاج الهيدروجين الأخضر ودور عناصر التدفئة

ما هو الهيدروجين الأخضر ، ولماذا هو مهم؟

الهيدروجين الأخضر ، الذي يتم إنتاجه من خلال التحليل الكهربائي للمياه مدعوم من الطاقة المتجددة ، هو حجر الزاوية في استراتيجيات الطاقة المستدامة. على عكس الهيدروجين الرمادي ، الذي ينبعث منه 830 مليون طن من CO₂ سنويًا ، يوفر الهيدروجين الأخضر بديلاً خاليًا من الكربون. هذا أمر بالغ الأهمية مع وصول استهلاك الهيدروجين العالمي ما يقرب من 70 مليون طن، ولكن أقل من 1% يأتي من مصادر متجددة. يمكن أن يؤدي الانتقال إلى الهيدروجين الأخضر إلى تقليل الانبعاثات بشكل كبير ، حيث يتماشى مع أهداف Net-Zero العالمية.

عملية التحليل الكهربائي ومتطلبات التدفئة

يقسم التحليل الكهربائي الماء إلى الهيدروجين والأكسجين باستخدام الكهرباء. تتطلب هذه العملية تسخين دقيق للحفاظ على ظروف التفاعل المثلى. إنتاج 1 كيلوغرام من متطلبات الهيدروجين الأخضر حوله 9 لتر من الماء، مع 10-20 لتر إضافية لتنقية والتبريد. يضمن التدفئة الموحدة والفعالة أن العملية تعمل بفعالية ، مما يقلل من نفايات الطاقة. تقنيات التدفئة المتقدمة ، مثل عنصر التدفئة كذا، لعب دورًا محوريًا في تحقيق هذه الظروف ، مما يوفر الموصلية الحرارية والموثوقية العالية.

قيود تقنيات التدفئة التقليدية

غالبًا ما تكافح طرق التدفئة التقليدية مع تطبيقات درجات الحرارة العالية. ارتفاع كثافة الطاقة في أنظمة مثل لوحات الدوائر المطبوعة يؤدي إلى حرارة مفرطة ، والمكونات الضارة وتسبب فشل النظام. يمكن أن تؤدي الضغوط الميكانيكية من الاختلافات التوسع الحراري إلى مشكلات التكسير والاتصال ، خاصة في ظل التسخين الدوري. هذه القيود تسلط الضوء على الحاجة حلول مبتكرة مثل عناصر التدفئة القائمة على كربيد السيليكون ، والتي توفر المتانة والأداء المتسق في البيئات الصعبة.

مزايا عناصر التدفئة SIC في إنتاج الهيدروجين الأخضر

كفاءة درجات الحرارة العالية والتوصيل الحراري

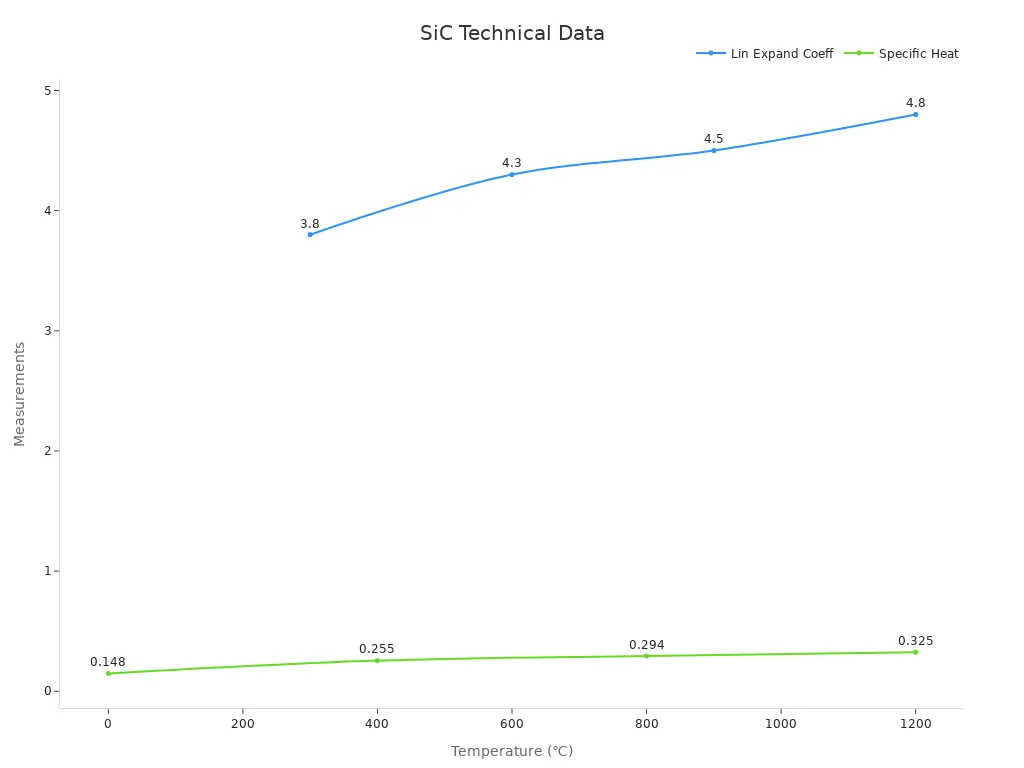

تتفوق عناصر تسخين كربيد السيليكون في تطبيقات درجات الحرارة العالية بسبب الموصلية الحرارية والكفاءة الفائقة. تحافظ هذه العناصر على أداء مستقر حتى في درجات الحرارة القصوى ، مما يجعلها مثالية لعمليات إنتاج الهيدروجين الأخضر مثل التحليل الكهربائي. يسلط الجدول التالي الضوء على الخصائص الحرارية لعناصر التدفئة SIC عبر نطاقات درجات الحرارة المختلفة:

| درجة الحرارة (℃) | معامل التوسع الخطي (10⁻⁶m/℃) | الموصلية الحرارية (KCAL/M HR ℃) | حرارة محددة (Cal/G ℃) |

|---|---|---|---|

| 0 | / | / | 0.148 |

| 300 | 3.8 | / | / |

| 400 | / | / | 0.255 |

| 600 | 4.3 | 14-18 | / |

| 800 | / | / | 0.294 |

| 900 | 4.5 | / | / |

| 1100 | / | 12 | / |

| 1200 | 4.8 | / | 0.325 |

| 1300 | / | 10 | / |

توضح البيانات أن عناصر التدفئة SIC تحافظ على توصيل حراري عالي حتى في درجات حرارة مرتفعة ، مما يضمن نقل الحرارة الفعال. هذه القدرة تقلل من فقدان الطاقة وتعزز الكفاءة الكلية لأنظمة إنتاج الهيدروجين الخضراء. يوضح الرسم البياني أدناه اتجاهات الأداء الحراري للمواد SIC:

المتانة والمقاومة للتآكل الكيميائي

تقدم عناصر التدفئة كذا احتمالية استثنائية ومقاومة التآكل الكيميائي ، مما يجعلها خيارًا موثوقًا للبيئات الصناعية الصعبة. يتيح لهم تكوينهم الفريد مواجهة التفاعلات الكيميائية القاسية والحفاظ على النزاهة الهيكلية مع مرور الوقت. تشمل النتائج الرئيسية التي تدعم مقاومة التآكل:

- معدل التآكل في Cu/20SIC أقل بشكل ملحوظ مقارنة بالمواد الأخرى ، مما يشير مقاومة متفوقة.

- يؤدي زيادة محتوى SIC إلى 20% إلى تحويل إمكانات التآكل (ECORR) إلى قيمة أكثر نبيلة ، مما يعزز سلبية المادة.

- يزيد محتوى SIC الأعلى من معامل المقاومة ، مما يؤدي إلى تحسين مقاومة التآكل.

- يتشكل فيلم سلبي رفيع على سطح المركبات المقوى بالكيك ، بمثابة حاجز وقائي ضد الهجمات الكيميائية.

تضمن هذه الخصائص أن عناصر التدفئة SIC يمكن أن تتحمل التعرض المطول للبيئات المآمجة ، مما يقلل من الحاجة إلى بدائل متكررة وتقليل وقت التوقف في مرافق إنتاج الهيدروجين الخضراء.

توفير الطاقة وخفض التكاليف التشغيلية

يؤدي استخدام عناصر التدفئة SIC في إنتاج الهيدروجين الأخضر إلى وفورات كبيرة في الطاقة وخفض التكاليف التشغيلية. تقلل كفاءتها الحرارية العالية من استهلاك الطاقة بما يصل إلى 30% ، كما هو موضح في الجدول أدناه:

| القياس | القيمة |

|---|---|

| الحد من استهلاك الطاقة | ما يصل إلى 30% |

| تخفيض تكاليف الصيانة | عمر أطول |

| تردد الاستبدال | أقل تواترا |

من خلال استهلاك طاقة أقل ، تساهم هذه العناصر في عملية إنتاج هيدروجين أكثر استدامة وفعالة من حيث التكلفة. تعمل متطلبات الصيانة الممتدة على عمرها على تعزيز الكفاءة التشغيلية الخاصة بها ومتطلبات الصيانة ، مما يجعلها خيارًا مفضلاً للتطبيقات على نطاق صناعي. لا يدعم تكامل عناصر التدفئة SIC في أنظمة الهيدروجين الخضراء الأهداف البيئية فحسب ، بل يوفر أيضًا فوائد اقتصادية ملموسة.

التطبيقات الحالية لعناصر التدفئة SIC

عناصر التدفئة كذا في أنظمة التحليل الكهربائي عالية درجة الحرارة

عناصر التدفئة كذا أصبحت لا غنى عنها في أنظمة التحليل الكهربائي عالية درجة الحرارة ، حيث يكون التحكم الحراري الدقيق أمرًا بالغ الأهمية. تعتمد هذه الأنظمة على درجات حرارة مرتفعة لتعزيز كفاءة تقسيم المياه ، وهي عملية أساسية لإنتاج الهيدروجين الأخضر. إن قدرة عناصر التدفئة SIC على الحفاظ على أداء مستقر في درجات حرارة تتجاوز 1800 درجة مئوية يضمن التشغيل المتسق في ظل ظروف صعبة. يقلل الموصلية الحرارية العالية من فقدان الطاقة ، مما يتيح نقل الحرارة بشكل أسرع وتوزيع درجة الحرارة الموحدة عبر غرفة التحليل الكهربائي. هذا التوحيد يقلل من خطر ارتفاع درجة الحرارة المحلية ، والتي يمكن أن تعرض لسلامة النظام.

تستفيد الصناعات التي تتبنى عناصر التدفئة SIC من عمرها الممتد ومتطلبات الصيانة المنخفضة. على عكس تقنيات التدفئة التقليدية ، التي تتدهور في كثير من الأحيان في ظل الظروف القاسية ، تقاوم مواد SIC الصدمة الحرارية والإجهاد الميكانيكي. تترجم هذه المتانة إلى عدد أقل من الاضطرابات التشغيلية ، مما يجعلها خيارًا موثوقًا لمرافق إنتاج الهيدروجين على نطاق واسع. من خلال دمج عناصر التدفئة SIC ، يمكن للشركات تحقيق كفاءة إخراج أعلى مع خفض التكاليف التشغيلية.

التكامل مع مصادر الطاقة المتجددة مثل الطاقة الشمسية والرياح

تكامل SIC عناصر التدفئة مع مصادر الطاقة المتجددة فتحت إمكانيات جديدة لإنتاج الهيدروجين المستدام. في التطبيقات الحرارية الشمسية ، تلعب عناصر التدفئة SIC دورًا محوريًا في تركيز أنظمة الطاقة الشمسية. تستخدم هذه الأنظمة المرايا أو العدسات لتركيز أشعة الشمس على جهاز الاستقبال ، حيث تتفوق مواد SIC بسبب استقرارها في درجات الحرارة العالية والخصائص الحرارية الاستثنائية. وقد أظهرت المظاهرات أن مستقبلات الهواء الشمسي المركّز في SIC يمكنها تحقيقها الخروج من درجات حرارة الهواء القريبة من 800 درجة مئوية. هذه القدرة تعزز بشكل كبير من كفاءة الأنظمة الحرارية الشمسية ، مما يجعلها أكثر قابلية للتطبيقات على النطاق الصناعي.

تستفيد أنظمة طاقة الرياح أيضًا من القدرة على تكييف عناصر التدفئة SIC. من خلال إقران هذه العناصر مع الكهرباء التي تم إنشاؤها للرياح ، يمكن للمشغلين تخزين الطاقة الزائدة كحرارة لاستخدامها لاحقًا في إنتاج الهيدروجين. يعالج هذا النهج الطبيعة المتقطعة لمصادر الطاقة المتجددة ، مما يضمن إمدادات ثابتة من الطاقة لعمليات التحليل الكهربائي. يؤكد التآزر بين عناصر التدفئة SIC وتقنيات الطاقة المتجددة قدرتها على دفع الانتقال نحو مستقبل محايد للكربون.

مشاريع الهيدروجين الخضراء على نطاق صناعي تتميز بتكنولوجيا SIC

لقد تبنت العديد من مشاريع الهيدروجين الخضراء على نطاق صناعي تقنية SIC بالفعل لتلبية متطلبات درجات الحرارة العالية. تستفيد هذه المشاريع من الخصائص الفريدة لعناصر التدفئة SIC لتحسين الكفاءة وتقليل استهلاك الطاقة. على سبيل المثال ، أبلغت نباتات التحليل الكهربائي على نطاق واسع المجهزة بعناصر التدفئة SIC عن تحسينات كبيرة في الاستقرار التشغيلي واتساق الإخراج. تضمن قدرة هذه العناصر على الصمود إجراءات صناعية قاسية الإنتاج دون انقطاع ، حتى في ظل التشغيل المستمر.

لعبت شركة Ningbo Vet Energy Technology Co. ، Ltd دورًا أساسيًا في التقدم في اعتماد عناصر التدفئة SIC في مثل هذه المشاريع. من خلال توفير حلول متطورة مصممة لاحتياجات مرافق الهيدروجين الخضراء ، أظهرت الشركة التزامها بالابتكار والاستدامة. تشمل مساهماتهم تطوير أنظمة التدفئة SIC المخصصة المصممة لدمجها بسلاسة مع مصادر الطاقة المتجددة. تسلط هذه التطورات الضوء على الدور المتزايد لتكنولوجيا SIC في تشكيل مستقبل إنتاج الهيدروجين الأخضر.

الاتجاهات المستقبلية لعناصر التدفئة كذا

التقدم التكنولوجي في مواد كذا

يستمر تطوير مواد كربيد السيليكون (SIC) في التطور ، مدفوعًا بالابتكارات في تقنيات التوليف وتقنيات التطبيق. وقد عززت طرق محسّنة مثل ترسب البخار الكيميائي (CVD) وعمليات SOL-GEL نقاء وأداء مواد SIC. تتيح هذه التطورات تحكمًا أكبر في الخصائص ، مما يجعلها مناسبة للتطبيقات عالية الدقة. ظهرت تقنيات وظائف السطح أيضًا ، مما أدى إلى تحسين توافق SIC مع مختلف الأنظمة الصناعية. يضمن هذا التقدم أن مواد SIC تلبي المتطلبات المتزايدة للصناعات مثل الإلكترونيات والطاقة.

يمثل تكامل المواد الهجينة اتجاهًا مهمًا آخر. من خلال الجمع بين SIC والمواد الأخرى ، يمكن للمصنعين إنشاء مركبات مع وظائف مصممة. على سبيل المثال ، تعزز المواد الهجينة الموصلية الحرارية مع الحفاظ على السلامة الهيكلية. من المتوقع أن يشهد قطاع Nano SIC ، بخصائصه المتفوقة ، نموًا أعلى في التطبيقات المتقدمة. يسلط الجدول أدناه الضوء على الاتجاهات الرئيسية التي تشكل مستقبل مواد SIC:

| الاتجاه الرئيسي | الوصف |

|---|---|

| تحسن تقنيات التوليف | تقدم التطورات في طرق مثل CVD و SOL-GEL تعزيز النقاء والتحكم في الخصائص. |

| توظيف السطح | تقنيات جديدة تعمل على تحسين التشتت والتوافق في التطبيقات المختلفة. |

| المواد الهجينة | تطوير المركبات التي تجمع بين SIC مع مواد أخرى للوظائف المصممة خصيصًا. |

| شريحة نانو كذا | إمكانات نمو أعلى بسبب الخصائص الفائقة للتطبيقات المتقدمة. |

تخفيض التكاليف وقابلية التوسع للتبني على نطاق واسع

تعتمد قابلية توسع عناصر التدفئة SIC على تقليل تكاليف الإنتاج دون المساس بالجودة. يستكشف الشركات المصنعة تقنيات إنتاج فعالة لتحقيق هذا الهدف. لقد أظهرت أساليب التوليف بالجملة والأتمتة في عمليات التصنيع بالفعل وعدًا في خفض التكاليف. مع نمو الطلب على مواد SIC ، ستزيد وفورات الحجم من الأسعار ، مما يجعل هذه العناصر أكثر سهولة للتطبيقات الصناعية.

تلعب الحوافز والاستثمارات الحكومية في التقنيات الخضراء أيضًا دورًا مهمًا. تشجع الإعانات على مشاريع الطاقة المتجددة تبني عناصر التدفئة SIC في إنتاج الهيدروجين الأخضر. هذه المبادرات لا تقلل فقط من التكاليف الأولية ولكن أيضًا تعزز الاستدامة طويلة الأجل. من خلال معالجة حواجز التكلفة ، يمكن لتكنولوجيا SIC تحقيق اعتماد واسع النطاق في مختلف القطاعات.

دور في تحقيق أهداف انبعاثات الشبكات الصافية العالمية

تعتبر عناصر التدفئة SIC محورية في الدفعة العالمية نحو انبعاثات الشبكة الصافية. يقلل كفاءتها الحرارية العالية من استهلاك الطاقة ، مما يقلل مباشرة من آثار أقدام الكربون في العمليات الصناعية. عند دمجها مع مصادر الطاقة المتجددة ، تتيح هذه العناصر إنتاج الهيدروجين الأخضر - وهو مكون رئيسي في قطاعات إزالة الكربون مثل النقل والتصنيع.

تعمل البلدان في جميع أنحاء العالم على تحديد أهداف طموحة لخفض الانبعاثات. تتماشى تقنية SIC مع هذه الأهداف من خلال تقديم حل مستدام للتطبيقات عالية الحرارة. يؤكد دوره في إنتاج الهيدروجين الأخضر على أهميته في تحقيق مستقبل محايد للكربون. مع انتقال الصناعات إلى أنظمة الطاقة الأنظف ، سيستمر الطلب على عناصر التدفئة SIC في الارتفاع ، مما يعزز موقعها كحجرات للابتكار المستدام.

Ningbo Vet Energy Technology Co. ، Ltd وعناصر التدفئة SIC

مساهمات شركة Ningbo Vet Energy Technology Co. ، LTD لابتكار SIC

Ningbo VET Energy Technology Co., Ltd برزت كقائد في تطوير تقنيات كربيد السيليكون المتقدمة. استثمرت الشركة بكثافة في الأبحاث لتعزيز أداء وموثوقية مواد SIC. من خلال الاستفادة من تقنيات التصنيع الملكية ، حققت اختراقات في الكفاءة الحرارية والمتانة. وضعت هذه الابتكارات الشركة كلاعب رئيسي في قطاع الهيدروجين الأخضر. وتشمل مساهماتها تطوير عناصر التدفئة عالية الأداء SIC المصممة خصيصًا للتطبيقات على نطاق صناعي. توفر هذه العناصر نتائج متسقة حتى في ظل الظروف القاسية ، مما يجعلها لا غنى عنها لأنظمة إنتاج الهيدروجين الحديثة.

دراسات حالة لتطبيقات عنصر التدفئة الناجحة SIC

تبرز العديد من المشاريع الصناعية فعالية شركة Ningbo Vet Energy Technology Co. ، Ltd's Solutions. يتضمن أحد الأمثلة البارزة مصنعًا كهربائيًا واسع النطاق يتبنى عنصر التدفئة SIC للشركة لتحسين عملياتها. أبلغ المصنع عن انخفاض 25% في استهلاك الطاقة وتحسين كبير في استقرار النظام. تتميز دراسة حالة أخرى بمرفق هيدروجين حراري شمسي حيث مكّن عناصر التدفئة SIC نقل حرارة فعال ، وتحقيق درجات حرارة تتجاوز 1000 درجة مئوية. توضح هذه التطبيقات في العالم الحقيقي براعة وموثوقية منتجات الشركة في إعدادات متنوعة.

الالتزام بتقدم تقنيات إنتاج الهيدروجين الخضراء

لا تزال شركة Ningbo Vet Energy Technology Co. ، LTD ملتزمة بقيادة الابتكار في إنتاج الهيدروجين الأخضر. تتعاون الشركة مع الشركاء العالميين لتطوير مواد SIC من الجيل التالي التي تتماشى مع أهداف الاستدامة. يمتد تركيزها إلى ما هو أبعد من تطوير المنتج ليشمل الدعم الشامل للعملاء ، مما يضمن التكامل السلس لعناصر التدفئة SIC في أنظمتهم. من خلال إعطاء الأولوية للكفاءة والتأثير البيئي ، تلعب الشركة دورًا محوريًا في النهوض بالانتقال العالمي إلى الطاقة النظيفة.

توفر عناصر تسخين كربيد السيليكون كفاءة لا مثيل لها ، ومتانة ، وفعالية من حيث التكلفة ، مما يجعلها لا غنى عنها في إنتاج الهيدروجين الأخضر. لا يمكن إنكار دورهم في تقدم أهداف الطاقة المستدامة.

- من المتوقع أن ينمو سوق وحدة الطاقة SIC $1.2 مليار في 2023 إلى $9.5 مليار بحلول عام 2032، مدفوعة بالطاقة المتجددة والتقدم في المركبات الكهربائية.

- تفوق وحدات SIC الأنظمة التقليدية القائمة على السيليكون ، ودعم حلول النقل والطاقة المستدامة.

سيؤدي مزيد من البحث والاستثمار في تكنولوجيا SIC إلى فتح إمكاناتها الكاملة ، مما يؤدي إلى تسريع الانتقال العالمي إلى الطاقة النظيفة.

FAQ

ما الذي يجعل عناصر التدفئة SIC متفوقة على تقنيات التدفئة التقليدية؟

تتفوق عناصر التدفئة SIC بسبب كفاءتها الحرارية العالية ، والمتانة ، ومقاومة التآكل الكيميائي. هذه الميزات تضمن أداء موثوقًا به في البيئات الصناعية المتطرفة.

Tip: عناصر التدفئة SIC تقلل من استهلاك الطاقة بنسبة تصل إلى 30% ، مما يجعلها خيارًا فعالًا من حيث التكلفة إنتاج الهيدروجين الأخضر.

كيف تسهم عناصر التدفئة SIC في الاستدامة؟

تتيح عناصر التدفئة SIC إنتاج الهيدروجين الأخضر الفعال عن طريق تقليل نفايات الطاقة. يدعم تكاملهم مع مصادر الطاقة المتجددة الجهود العالمية لتحقيق انبعاثات الصافية الصافية.

هل يمكن تخصيص عناصر التدفئة SIC لتطبيقات محددة؟

نعم ، تقدم الشركات المصنعة مثل Ningbo Vet Energy Technology Co. ، Ltd حلول تسخين SIC المصممة خصيصًا. هؤلاء تصميمات مخصصة تلبية المتطلبات الفريدة لمختلف العمليات الصناعية.

ملاحظة: يضمن التخصيص الأداء الأمثل والتكامل السلس في الأنظمة الحالية.