Precision is essential in aerospace applications. SiC Coating provides exceptional durability, thermal resistance, and lightweight performance, making it a vital choice for aerospace components. Advanced solutions, including CVD SIC COATING and TAC COATING, are designed to optimize functionality in challenging environments. Ningbo VET Energy Technology Co., Ltd utilizes cutting-edge technologies like CVD TAC COATING to offer customized coatings that adhere to rigorous industry standards.

Key Takeaways

- SiC coatings are strong, heat-resistant, and lightweight, perfect for aerospace parts.

- These coatings help turbine blades last 15-20% longer. This lowers repair costs and saves time.

- Special methods like CVD and APS create custom SiC coatings. These meet strict rules set by OEMs.

Why SiC Coating Is Essential for Aerospace Applications

Key properties of SiC coatings for aerospace

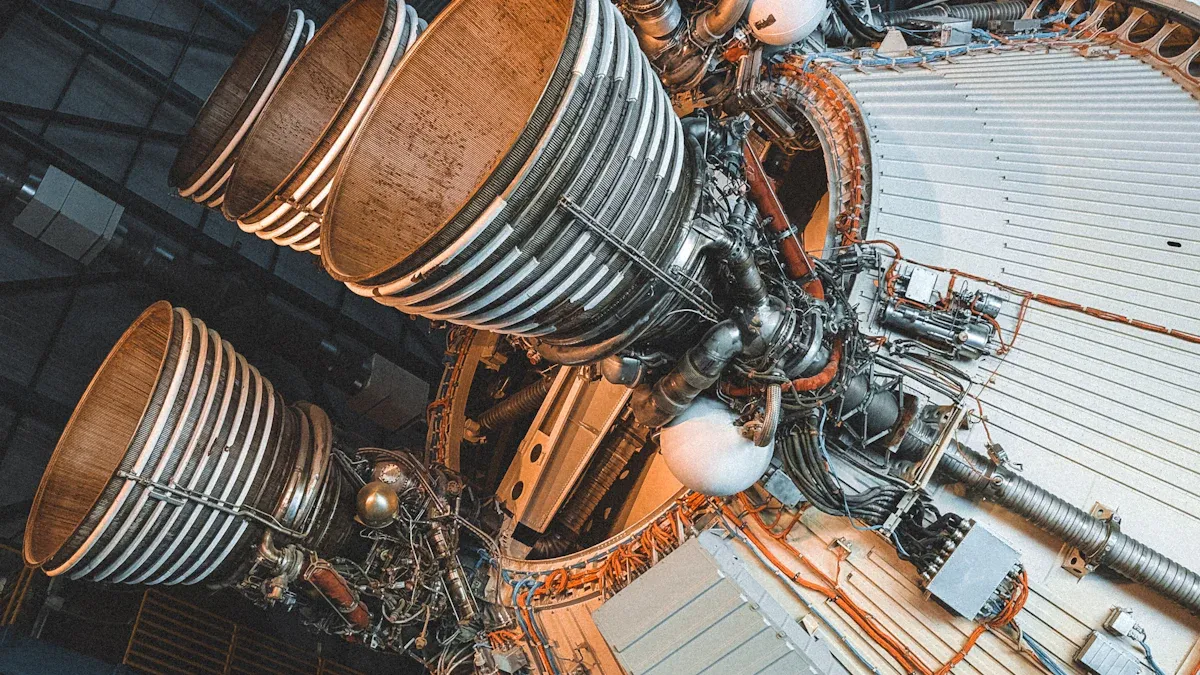

SiC coatings possess unique properties that make them indispensable in aerospace applications. These coatings exhibit exceptional thermal resistance, enabling them to withstand extreme temperatures often encountered in aerospace environments. For instance, components like turbine blades and combustion chambers operate at temperatures exceeding 1,500°C. SiC coatings protect these parts by resisting oxidation and thermal shock, ensuring their longevity and performance.

Durability is another critical attribute of SiC coatings. They provide superior resistance to wear and corrosion, even under high-stress conditions. This durability reduces the frequency of maintenance and replacement, leading to cost savings for aerospace manufacturers. Additionally, SiC coatings are lightweight, which is crucial for aerospace applications where minimizing weight directly impacts fuel efficiency and overall performance.

Tip: The combination of thermal resistance, durability, and lightweight properties makes SiC coatings a preferred choice for aerospace engineers seeking reliable and efficient solutions.

Applications of SiC coatings in critical aerospace components

SiC coatings play a vital role in protecting and enhancing the performance of critical aerospace components. These include:

- Turbine Blades: SiC coatings extend the lifespan of turbine blades by 15-20%, reducing maintenance costs and downtime.

- Combustion Chambers: The coatings provide thermal insulation and prevent oxidation, ensuring consistent performance in high-temperature environments.

- Spacecraft Components: SiC coatings offer radiation resistance, making them ideal for parts exposed to strong radiation in space.

- Aerospace Sensors: These coatings enhance the durability and accuracy of sensors used in extreme conditions.

By applying SiC coatings to these components, aerospace manufacturers can achieve higher reliability and efficiency in their operations.

Advantages of SiC coatings over alternative materials in aerospace

SiC coatings outperform alternative materials in several key areas. A comparison of their benefits highlights why they are the preferred choice for aerospace applications:

| Benefit | Description |

|---|---|

| High Melting Point | SiC coatings can withstand extreme temperatures, making them ideal for high-temperature aerospace applications. |

| Radiation Resistance | They provide reliable performance in environments with strong radiation, crucial for aerospace components. |

| Durability | SiC enhances the reliability and service life of aerospace equipment, particularly in extreme environments. |

In addition to these advantages, SiC coatings offer unmatched thermal stability, significant weight reduction, and superior resistance to corrosion and wear. These properties ensure that aerospace components maintain optimal performance even in the most challenging conditions.

Note: The use of SiC coatings not only improves the functionality of aerospace components but also contributes to the overall advancement of aerospace technology.

Customizing SiC Coatings to Meet OEM Precision Requirements

Understanding OEM-specific needs and aerospace precision standards

Original Equipment Manufacturers (OEMs) in the aerospace sector demand coatings that meet stringent precision standards. These requirements stem from the need to ensure optimal performance, reliability, and safety in critical applications. SiC Coating solutions must align with specifications such as mechanical strength, thermal conductivity, and environmental durability.

| Specification Type | Details |

|---|---|

| Mechanical Properties | Exceptional hardness and strength critical for high-performance applications. |

| Thermal Conductivity | Outstanding thermal conductivity essential for heat management in various industries. |

| Customization Options | Tailored solutions based on precise drawings and specifications. |

| Industry Applications | Used in aerospace, automotive, electronics, energy, and manufacturing sectors. |

| Specific Use Cases | Essential in cutting tools, semiconductor substrates, heat exchangers, and braking systems. |

OEMs often require custom sizes and shapes to fit specific application needs. Enhanced features, such as improved production efficiency and accuracy, are critical for meeting aerospace precision standards. When designing thin film coatings, considerations include spectral performance, wavebands, angles of incidence, polarization, and durability. Ningbo VET Energy Technology Co., Ltd excels in tailoring SiC Coating solutions to meet these exacting demands, ensuring compliance with industry-specific requirements.

Advanced SiC coating technologies

Advanced technologies like Chemical Vapor Deposition (CVD) and Atmospheric Plasma Spraying (APS) play a pivotal role in achieving high-performance SiC coatings. CVD enables the creation of uniform, high-purity coatings with exceptional adhesion. APS, on the other hand, offers flexibility in adjusting plasma gas parameters to achieve optimal deposition efficiency.

Atmospheric Plasma Spraying (APS):

APS allows for significant variation in temperature and velocity of the plasma gas stream. By optimizing parameters such as plasma gas type, flow rate, and current, APS achieves deposition efficiencies higher than those reported in existing literature. This method produces silicon coatings with low porosities comparable to Vacuum Plasma Spraying (VPS), ensuring durability and reliability.

Chemical Vapor Deposition (CVD):

CVD is ideal for applications requiring thin, uniform coatings with high thermal stability. It ensures precise control over coating thickness and composition, making it suitable for aerospace components exposed to extreme conditions.

These technologies enable Ningbo VET Energy Technology Co., Ltd to deliver SiC Coating solutions that meet the unique demands of aerospace OEMs, ensuring superior performance and longevity.

Quality assurance processes to ensure coating performance and reliability

Quality assurance is integral to validating the reliability and performance of SiC coatings in aerospace applications. Ningbo VET Energy Technology Co., Ltd employs rigorous testing methods to ensure coatings meet mechanical and thermal reliability metrics.

Note: Mechanical tests, thermodilatometry, and microstructural analysis are essential for evaluating coating quality. These methods identify variations in thermal expansion that can lead to uneven thermal deformation, affecting performance.

Non-destructive testing techniques are also utilized to detect potential flaws without compromising the integrity of the coated components. By adhering to stringent quality assurance protocols, Ningbo VET Energy Technology Co., Ltd guarantees that its SiC Coating solutions deliver consistent performance under demanding aerospace conditions.

Addressing Challenges in Aerospace SiC Coating Applications

Common challenges in aerospace environments

Aerospace environments present unique challenges that demand advanced material solutions. Components often face extreme temperatures, which can exceed 1,500°C in engine systems. These conditions lead to thermal stress and oxidation, compromising material integrity. Additionally, material compatibility issues arise when coatings interact with substrates, potentially causing delamination or reduced adhesion. The presence of corrosive agents, such as salt and moisture, further exacerbates wear and degradation. Addressing these challenges requires coatings that combine thermal resistance, durability, and chemical stability.

Tailored solutions for overcoming these challenges

Tailored solutions, such as additive formulations and surface preparation techniques, play a critical role in overcoming aerospace coating challenges. For instance, grit blasting enhances surface roughness, improving the adhesion of coatings to smooth substrates. Research on cold-sprayed A357 aluminum alloy coatings highlights how optimized spray parameters and surface preparation can significantly improve bonding strength. Furthermore, advanced formulations, including nanotechnology-based coatings, enhance fuel efficiency, durability, and corrosion resistance. Thermal barrier coatings reduce heat transfer, improving engine performance, while smart coatings with self-healing properties extend aircraft lifespan and provide real-time data on stress and corrosion.

Collaboration between Ningbo VET Energy Technology Co., Ltd and OEMs for successful implementation

Ningbo VET Energy Technology Co., Ltd collaborates closely with OEMs to address these challenges effectively. By understanding specific operational requirements, the company develops SiC Coating solutions tailored to meet stringent aerospace standards. Their expertise in advanced technologies, such as Chemical Vapor Deposition, ensures coatings with superior adhesion and thermal stability. This partnership-driven approach enables OEMs to achieve reliable performance and extended service life for critical aerospace components.

Customized SiC coatings deliver unmatched thermal resistance, durability, and precision, making them indispensable for aerospace applications. Tailored solutions drive innovation by addressing unique challenges and enhancing component performance. Ningbo VET Energy Technology Co., Ltd invites OEMs to collaborate and leverage their expertise in advanced SiC coating technologies for superior aerospace solutions. ✈️

FAQ

What makes SiC coatings ideal for aerospace applications?

SiC coatings offer exceptional thermal resistance, durability, and lightweight properties. These features ensure reliable performance in extreme aerospace environments.

How does Ningbo VET Energy Technology Co., Ltd customize SiC coatings for OEMs?

The company tailors coatings using advanced technologies like CVD and APS. It ensures precise adherence to OEM specifications and aerospace standards.

Are SiC coatings suitable for high-temperature aerospace components?

Yes, SiC coatings withstand temperatures exceeding 1,500°C. They protect components like turbine blades and combustion chambers from oxidation and thermal stress.