CVD SiC Coating Solutions utilize advanced chemical vapor deposition technology to produce robust silicon carbide layers, designed to endure extreme temperatures and challenging environments. These coatings are vital for enhancing the durability and performance of semiconductor equipment, ensuring extended operational life. Industries depend on innovative solutions such as CVD TAC COATING and CVD SIC COATING to maintain efficiency and reliability in demanding conditions.

Key Takeaways

- CVD SiC Coating Solutions make semiconductor equipment last longer.

- Silicon carbide coatings handle high heat, staying strong over 1,000°C.

- Picking the right coating means checking material fit and needs.

What is CVD SiC Coating?

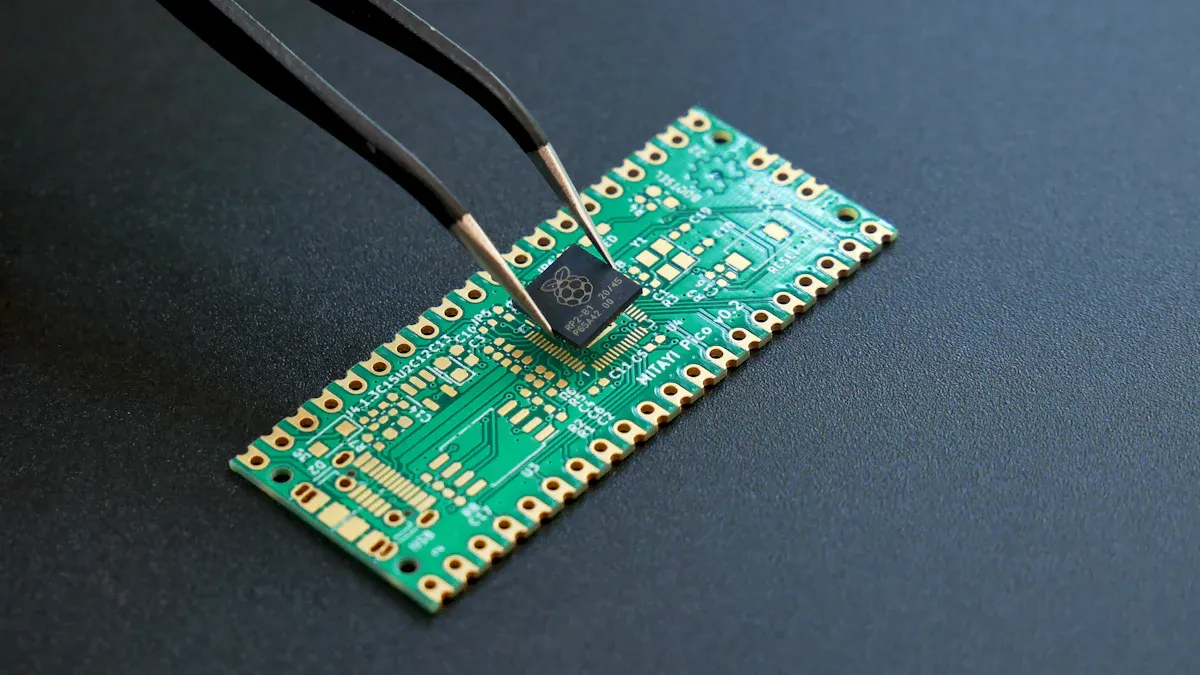

Chemical Vapor Deposition (CVD) Process Explained

Chemical Vapor Deposition (CVD) is a sophisticated manufacturing process used to create thin, durable coatings on various substrates. In this process, gaseous precursors react chemically in a controlled environment to deposit a solid material, such as silicon carbide (SiC), onto a surface. The reaction typically occurs at high temperatures, ensuring the formation of a uniform and high-purity coating.

The CVD process offers exceptional precision, allowing manufacturers to tailor the thickness and properties of the coating to meet specific application requirements. This adaptability makes it a preferred choice for industries that demand high-performance materials, including semiconductor equipment.

Tip: The CVD process ensures consistent quality and performance, making it ideal for applications requiring extreme durability and thermal stability.

Key Properties of Silicon Carbide (SiC)

Silicon carbide (SiC) is a compound renowned for its remarkable physical and chemical properties. These attributes make it a cornerstone material for high-temperature and high-stress applications.

- Thermal Conductivity: SiC exhibits excellent heat transfer capabilities, ensuring efficient thermal management.

- Hardness: With a Mohs hardness rating of 9, SiC is one of the hardest materials available, providing superior wear resistance.

- Chemical Stability: SiC resists corrosion and chemical degradation, even in harsh environments.

- Low Thermal Expansion: Its minimal thermal expansion ensures dimensional stability under extreme temperature fluctuations.

These properties collectively contribute to the reliability and longevity of SiC coatings, particularly in demanding semiconductor applications.

Why CVD SiC Coating Solutions Are Ideal for High-Temperature Applications

CVD SiC Coating Solutions stand out as the optimal choice for high-temperature applications due to their unique combination of properties. The coatings provide exceptional thermal resistance, ensuring stable performance even in environments exceeding 1,000°C. Their ability to withstand thermal cycling without cracking or degrading makes them indispensable for semiconductor equipment.

Additionally, the chemical inertness of SiC coatings protects equipment from corrosive gases and chemicals commonly encountered in semiconductor processes. This resistance minimizes maintenance requirements and extends the operational lifespan of critical components.

The durability of CVD SiC Coating Solutions also enhances wear resistance, reducing the risk of mechanical damage during prolonged use. By improving equipment reliability and efficiency, these coatings contribute to cost savings and operational excellence.

Note: Ningbo VET Energy Technology Co., Ltd specializes in providing tailored CVD SiC Coating Solutions that meet the rigorous demands of high-temperature semiconductor applications.

Benefits of CVD SiC Coating Solutions

Thermal Resistance and Stability

CVD SiC Coating Solutions excel in environments where extreme temperatures challenge equipment performance. Silicon carbide coatings maintain their structural integrity even at temperatures exceeding 1,000°C. This thermal stability ensures consistent operation without deformation or degradation. Semiconductor equipment often undergoes rapid temperature changes during processes like wafer fabrication. The low thermal expansion of silicon carbide prevents cracking, preserving the equipment’s functionality over time.

Tip: High thermal resistance reduces downtime caused by overheating, ensuring uninterrupted operations in critical applications.

Durability and Wear Resistance

Silicon carbide’s exceptional hardness makes CVD SiC Coating Solutions highly resistant to wear and mechanical damage. Equipment components coated with SiC can endure prolonged exposure to abrasive forces without losing their effectiveness. This durability is particularly valuable in semiconductor manufacturing, where precision and reliability are paramount. By minimizing wear, these coatings extend the lifespan of equipment, reducing replacement costs and operational disruptions.

- Key Advantages of Wear Resistance:

- Reduced maintenance frequency.

- Enhanced reliability in high-stress environments.

- Lower long-term operational costs.

Chemical and Corrosion Resistance

Semiconductor processes often involve exposure to corrosive gases and chemicals. CVD SiC Coating Solutions provide a robust barrier against chemical attacks, safeguarding equipment from degradation. Silicon carbide’s inert nature ensures that coated surfaces remain unaffected by harsh substances, maintaining their performance and appearance. This resistance is critical in plasma etching chambers and chemical vapor deposition reactors, where corrosive environments are common.

Note: Ningbo VET Energy Technology Co., Ltd offers customized CVD SiC Coating Solutions designed to withstand the most demanding chemical conditions.

Enhanced Operational Efficiency

By improving thermal management, durability, and chemical resistance, CVD SiC Coating Solutions contribute to enhanced operational efficiency. Equipment coated with silicon carbide operates reliably under challenging conditions, reducing the risk of unexpected failures. The coatings also optimize energy usage by maintaining consistent performance, even in high-temperature environments. This efficiency translates into cost savings and improved productivity for semiconductor manufacturers.

Callout: Investing in high-quality CVD SiC Coating Solutions ensures long-term value and operational excellence.

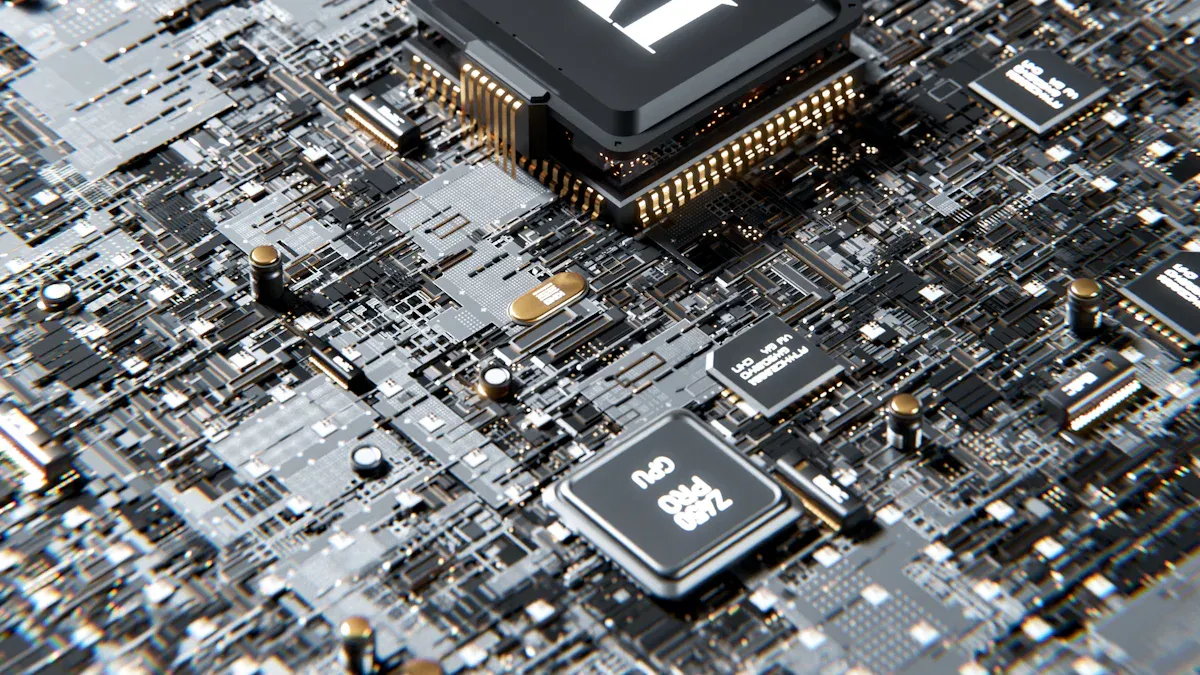

Applications of CVD SiC Coating Solutions in Semiconductor Equipment

Wafer Processing Equipment

Wafer processing equipment plays a critical role in semiconductor manufacturing. These machines operate under extreme conditions, including high temperatures and exposure to abrasive materials. CVD SiC Coating Solutions enhance the durability of wafer processing components by providing a robust protective layer. This coating minimizes wear and tear, ensuring consistent performance during repetitive operations. Additionally, the thermal stability of silicon carbide prevents deformation, maintaining the precision required for wafer fabrication.

Plasma Etching Chambers

Plasma etching chambers are essential for creating intricate patterns on semiconductor wafers. These chambers often encounter corrosive gases and high-energy plasma, which can degrade unprotected surfaces. CVD SiC Coating Solutions act as a barrier against chemical attacks, preserving the integrity of chamber components. The coatings also resist erosion caused by plasma exposure, extending the lifespan of the equipment. This reliability ensures uninterrupted production and reduces maintenance costs.

Chemical Vapor Deposition Reactors

Chemical vapor deposition reactors demand materials that can withstand high temperatures and reactive environments. CVD SiC Coating Solutions provide the necessary protection for reactor components, ensuring stable operation. The coatings’ chemical inertness prevents contamination, which is crucial for maintaining product quality. By enhancing the durability of reactor parts, these solutions contribute to efficient and reliable semiconductor manufacturing processes.

High-Temperature and Corrosive Environments

Semiconductor equipment often operates in environments where extreme heat and corrosive substances are present. CVD SiC Coating Solutions excel in these conditions by offering unmatched thermal resistance and chemical stability. The coatings protect critical components from degradation, ensuring long-term performance. This capability makes them indispensable for applications requiring both durability and precision.

How to Choose the Right CVD SiC Coating Solution

Compatibility with Equipment Materials

Selecting the right coating begins with evaluating the compatibility of CVD SiC Coating Solutions with the materials used in semiconductor equipment. Silicon carbide coatings must adhere effectively to the substrate without compromising its structural integrity. For instance, materials like graphite or silicon often pair well with these coatings due to their thermal and chemical properties. Manufacturers should assess the substrate’s thermal expansion coefficient to ensure alignment with the coating, preventing stress or cracking during high-temperature operations.

Performance and Application Requirements

Every semiconductor application has unique demands. Identifying the specific performance requirements, such as thermal resistance, chemical stability, or wear protection, is essential. For example, plasma etching chambers may prioritize chemical resistance, while wafer processing equipment might require enhanced durability. Tailoring the coating to meet these needs ensures optimal performance and longevity. Consulting with experts in CVD SiC Coating Solutions can help manufacturers align the coating properties with their operational goals.

Cost vs. Long-Term Value

While initial costs are a consideration, the long-term value of CVD SiC Coating Solutions often outweighs the upfront investment. These coatings reduce maintenance expenses, minimize downtime, and extend equipment lifespan. Evaluating the total cost of ownership provides a clearer picture of the financial benefits. Companies should focus on the durability and efficiency gains that these coatings deliver over time.

Partnering with Ningbo VET Energy Technology Co., Ltd for Reliable Solutions

Choosing a trusted partner ensures access to high-quality coatings and expert guidance. Ningbo VET Energy Technology Co., Ltd specializes in providing tailored CVD SiC Coating Solutions that meet the rigorous demands of semiconductor applications. Their expertise and commitment to innovation make them a reliable choice for manufacturers seeking durable and efficient coating solutions.

Maintenance and Longevity of CVD SiC Coating Solutions

Maintenance Best Practices

Proper maintenance ensures the longevity and performance of CVD SiC coatings. Regular cleaning of coated surfaces is essential to prevent the accumulation of debris or contaminants that may compromise the coating’s integrity. Using non-abrasive cleaning agents and soft materials helps avoid scratches or damage.

Operators should also monitor equipment operating conditions, such as temperature and chemical exposure, to ensure they remain within the recommended limits. Overexposure to extreme conditions can accelerate wear and reduce the coating’s effectiveness.

Tip: Establishing a routine maintenance schedule minimizes the risk of unexpected failures and extends the lifespan of the coating.

Identifying Wear and Degradation

Early identification of wear or degradation is critical for maintaining equipment efficiency. Signs of wear include discoloration, surface roughness, or reduced performance in high-temperature or corrosive environments. Regular visual inspections can help detect these issues before they escalate.

In addition to visual checks, performance monitoring tools can identify subtle changes in equipment behavior. For example, increased energy consumption or inconsistent processing results may indicate coating degradation.

Note: Addressing wear promptly prevents further damage and ensures uninterrupted operations.

Tips for Extending Coating Lifespan

To maximize the lifespan of CVD SiC coatings, operators should follow best practices tailored to their specific applications. Avoiding unnecessary mechanical stress and ensuring proper alignment of coated components reduces wear.

Maintaining optimal environmental conditions, such as stable temperatures and controlled chemical exposure, also enhances durability. Partnering with experts like Ningbo VET Energy Technology Co., Ltd ensures access to tailored solutions and professional guidance for long-term performance.

Callout: Proactive care and expert support are key to achieving maximum value from CVD SiC coatings.

CVD SiC Coating Solutions offer unmatched benefits for semiconductor equipment. Their thermal resistance, durability, and chemical stability enhance performance and extend equipment lifespan. These coatings ensure reliable operation in high-temperature environments. By partnering with Ningbo VET Energy Technology Co., Ltd, manufacturers can access customized solutions that meet their specific needs and operational goals.

FAQ

What are the primary benefits of CVD SiC coatings?

CVD SiC coatings offer thermal resistance, durability, and chemical stability. They enhance equipment performance and extend lifespan in high-temperature environments.

How do CVD SiC coatings improve semiconductor equipment efficiency?

These coatings optimize thermal management and reduce wear. They ensure reliable operation, minimizing downtime and maintenance costs.

Why choose Ningbo VET Energy Technology Co., Ltd for CVD SiC solutions?

Ningbo VET Energy Technology Co., Ltd provides tailored, high-quality CVD SiC solutions. Their expertise ensures reliable and efficient coatings for semiconductor applications.