Hitzebeständiger Glas-Kohle-Tiegel are specialized crucibles designed for high-temperature experiments and applications. They offer excellent heat resistance, chemical stability, and high purity, making them widely used in industries like metallurgy, ceramics, chemicals, and semiconductors.

Their production involves a complex process, including using high-purity materials like graphite and asphalt, undergoing high-temperature treatments, forming, sintering, annealing, grinding, and polishing to ensure top quality and performance.

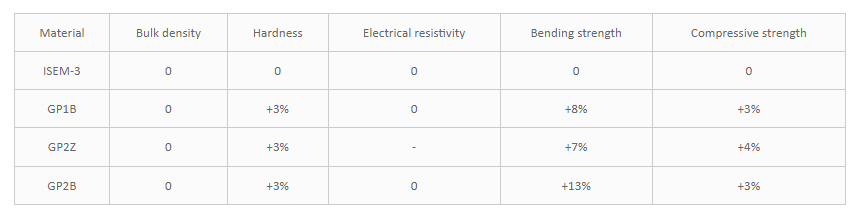

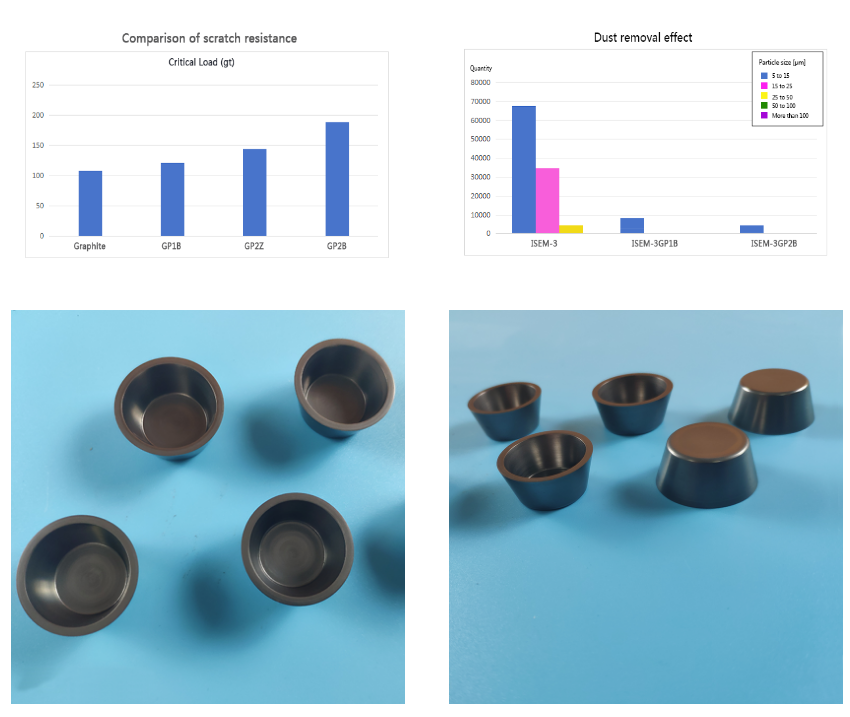

Hitzebeständiger Glas-Kohle-Tiegel features include compatibility with various graphite materials as substrates, maintaining the graphite substrate’s properties, reducing graphite dust formation, and offering improved scratch resistance and enhanced anti-friction durability.

We supply components for monocrystalline silicon drawing equipment, epitaxial growing parts, continuous casting dies, and glass seal fixtures. Let us know if you need more details!