EPI SUSCEPTORs are essential in epitaxial growth, acting as substrates to ensure uniform layer deposition. Their precise thermal management significantly boosts the efficiency of 5G chip production. Cutting-edge solutions like GRAPHITE SUSCEPTOR and CVD TAC COATING play a vital role in optimizing this process. Ningbo VET Energy Technology Co., Ltd is at the forefront of innovation in EPI SUSCEPTOR development.

Key Takeaways

- EPI susceptors spread heat evenly, helping make better semiconductor layers for 5G chips.

- Special materials like graphite and CVD TAC coatings make EPI susceptors stronger and more heat-resistant, lowering mistakes during chip-making.

- Ningbo VET Energy Technology Co., Ltd creates new EPI susceptor designs to make 5G chip production faster and easier to scale.

What Are EPI Susceptors?

Definition and Purpose

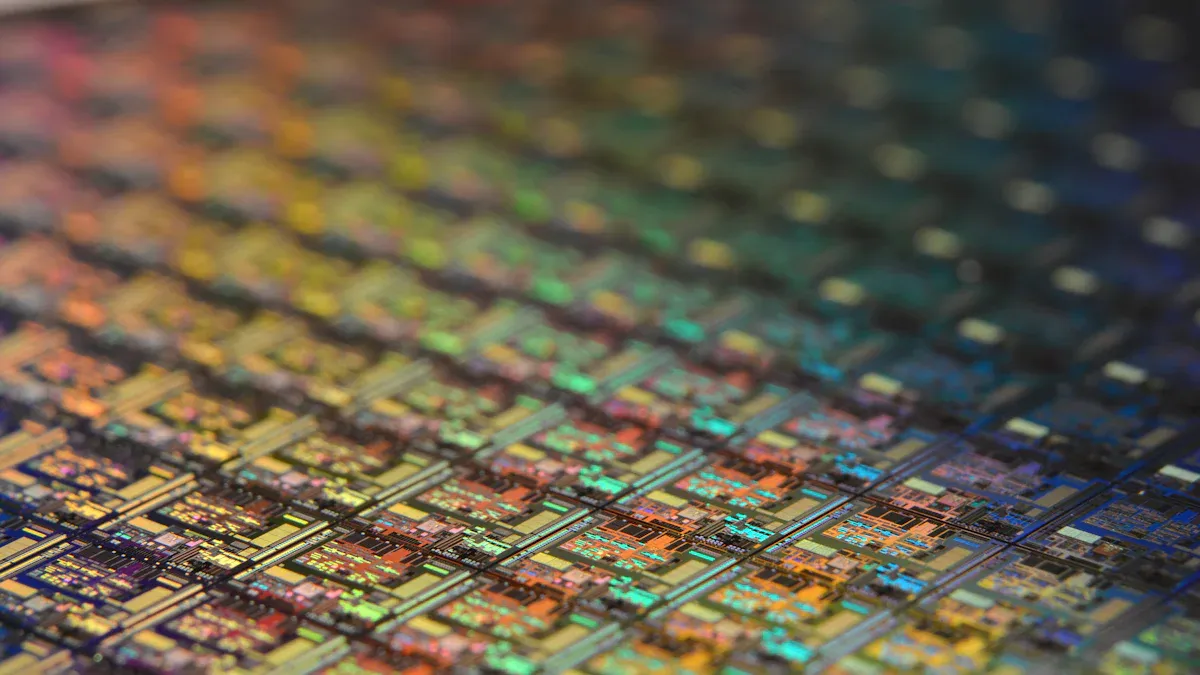

An EPI SUSCEPTOR serves as a critical component in the epitaxial growth process. It acts as a substrate holder, ensuring that the material being deposited forms a uniform and high-quality layer. These susceptors are typically made from materials like graphite or silicon carbide, which can withstand high temperatures and maintain structural integrity during the process. Their primary purpose is to provide a stable platform for the deposition of thin films, which are essential for manufacturing advanced semiconductor devices.

By facilitating precise thermal control, EPI SUSCEPTORs help achieve the uniformity required for high-performance chips. This makes them indispensable in industries like telecommunications, where 5G chip production demands exceptional precision and efficiency.

Function in Epitaxial Growth

Epitaxial growth involves depositing a crystalline layer on a substrate to create high-quality semiconductor materials. The EPI SUSCEPTOR plays a pivotal role in this process by ensuring even heat distribution across the substrate. This uniform heating prevents defects in the crystalline structure, which could compromise the performance of the final product.

Additionally, the susceptor’s material properties influence the efficiency of the chemical vapor deposition (CVD) process. For instance, a graphite susceptor with a CVD TAC coating enhances thermal conductivity and chemical resistance. These features enable the production of defect-free layers, which are crucial for the reliability of 5G chips.

Key Features of EPI Susceptors

EPI SUSCEPTORs are designed with specific features that optimize their performance in epitaxial growth. Some of the key attributes include:

- Thermal Stability: They can endure extreme temperatures without deforming or losing functionality.

- Chemical Resistance: Coatings like CVD TAC protect the susceptor from corrosive gases used during the deposition process.

- Precision Engineering: Their design ensures uniform heat distribution, which is vital for creating consistent crystalline layers.

- Durability: High-quality materials extend the lifespan of the susceptor, reducing the need for frequent replacements.

These features collectively enhance the efficiency and reliability of epitaxial growth, making EPI SUSCEPTORs a cornerstone of modern semiconductor manufacturing.

Epitaxial Growth and 5G Chip Production

Importance of Epitaxial Growth for 5G Chips

Epitaxial growth is a cornerstone of 5G chip production. It enables the creation of high-quality semiconductor layers essential for advanced RF devices. These layers enhance carrier mobility and power density, ensuring faster data transmission and improved energy efficiency. The growing demand for 5G networks and IoT devices underscores the critical role of epitaxial substrates in meeting market needs.

| Evidence Type | Description |

|---|---|

| Market Demand | The deployment of 5G networks is driving the need for RF devices, which utilize epitaxial substrates. |

| Performance Benefits | Epitaxial wafers enhance carrier mobility and power density, crucial for high-speed data transmission. |

| Future Projections | The IoT market is projected to reach USD 3,486.8 Billion by 2033, indicating growing demand for RF solutions. |

Challenges in Achieving High-Quality Layers

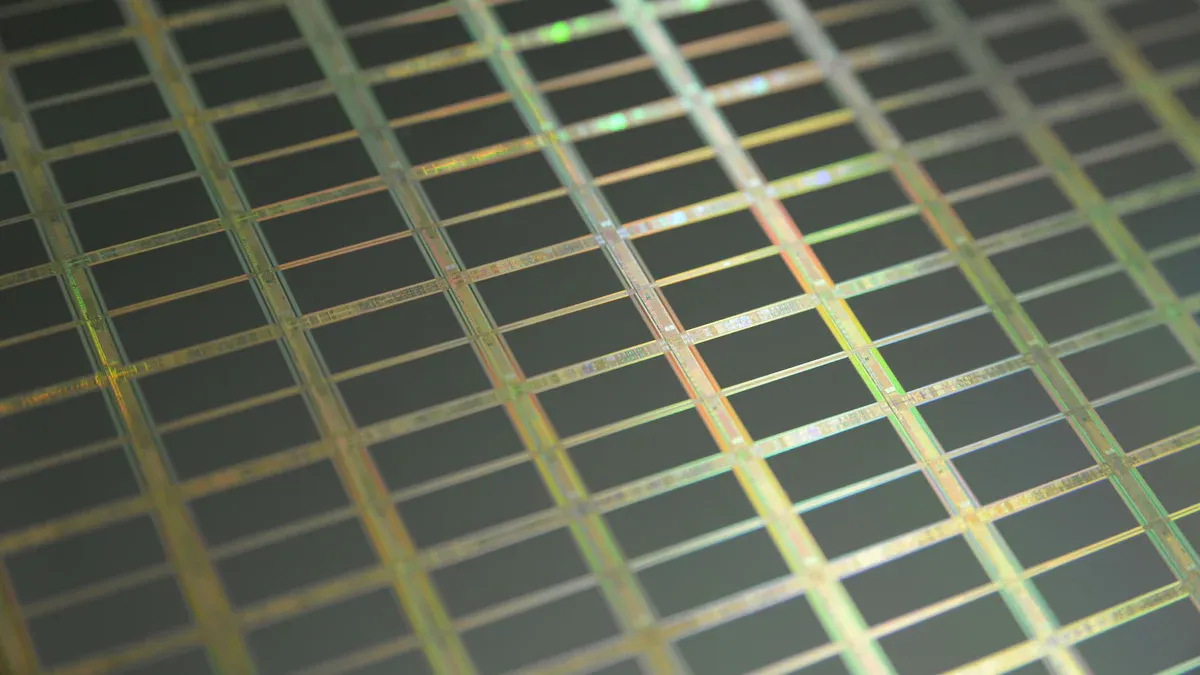

Producing defect-free epitaxial layers presents several challenges. Uniformity across large wafers is difficult to achieve, with variations exceeding 2-3% significantly impacting device performance. Defect detection tools often miss sub-surface flaws, while maintaining chemical purity adds substantial costs. Additionally, process control and yield management become increasingly complex as wafer sizes and production volumes grow.

| Challenge Type | Quantitative Evidence |

|---|---|

| Uniformity | Variations exceeding 2-3% across 300mm wafers impact device performance; 1nm deviation reduces carrier mobility by 15%. |

| Defect Detection | Allowable defect densities for 3nm-class devices below 0.035/cm²; current tools miss 20-25% of sub-surface defects. |

| Chemical Purity | Trace oxygen contamination below 50ppb degrades interfaces; maintaining sub-10ppb levels adds $2-3 per wafer. |

| Process Control | In-situ monitoring techniques exhibit 15-20% measurement error for multi-layer structures. |

| Yield Management | Silicon carbide epitaxy has defect densities of 500-1000/cm²; 450mm wafer prototypes show 35% thickness variation increase. |

| Parameter Spread | 14% increase in wafer-to-wafer spread when throughput exceeds 4,000 wafers/month. |

Role of EPI Susceptors in Overcoming Challenges

EPI SUSCEPTORs play a pivotal role in addressing these challenges. Their ability to ensure uniform heat distribution minimizes wafer variations, enhancing layer consistency. Advanced materials like graphite with CVD TAC coatings improve thermal conductivity and chemical resistance, reducing defect rates. By enabling precise process control, EPI SUSCEPTORs contribute to higher yields and scalability, making them indispensable for 5G chip production. Companies like Ningbo VET Energy Technology Co., Ltd continue to innovate in this field, driving advancements in epitaxial growth technology.

How EPI Susceptors Enhance Efficiency

Uniform Heat Distribution

Uniform heat distribution is a critical factor in epitaxial growth. EPI SUSCEPTORs excel in this area by ensuring that heat spreads evenly across the substrate during the deposition process. This uniformity minimizes temperature gradients, which can lead to defects in the crystalline structure. By maintaining consistent thermal conditions, EPI SUSCEPTORs help produce high-quality semiconductor layers with fewer imperfections.

Advanced materials like graphite, often used in EPI SUSCEPTORs, exhibit excellent thermal conductivity. This property allows them to transfer heat efficiently, ensuring that every part of the wafer receives the same level of thermal energy. As a result, manufacturers can achieve greater consistency in layer thickness and composition, which is essential for the performance of 5G chips.

Note: Uniform heat distribution not only improves the quality of the final product but also reduces the likelihood of costly rework or material waste.

Improved Material Quality

The material quality of semiconductor layers directly impacts the performance of 5G chips. EPI SUSCEPTORs contribute to improved material quality by providing a stable and controlled environment for epitaxial growth. Their precise engineering ensures that the deposition process occurs under optimal conditions, reducing the risk of contamination or structural defects.

Coatings like CVD TAC enhance the chemical resistance of EPI SUSCEPTORs, protecting them from the reactive gases used during deposition. This protection ensures that the susceptor remains intact and does not introduce impurities into the growing layer. Additionally, the high thermal stability of these susceptors allows them to maintain their performance over extended production cycles, further enhancing the reliability of the process.

The result is a semiconductor layer with superior electrical properties, such as higher carrier mobility and lower defect density. These attributes are crucial for meeting the demanding requirements of 5G technology, where even minor imperfections can significantly affect device performance.

Process Consistency and Scalability

EPI SUSCEPTORs play a vital role in ensuring process consistency and scalability in semiconductor manufacturing. Their ability to deliver uniform heat distribution and maintain material quality translates into a more predictable and repeatable production process. This consistency is essential for achieving high yields, especially as manufacturers scale up to meet the growing demand for 5G chips.

Scalability becomes increasingly important as wafer sizes continue to grow. EPI SUSCEPTORs designed for larger wafers must maintain the same level of performance as those used for smaller substrates. Advanced designs and materials enable these susceptors to handle the challenges of larger-scale production without compromising quality. This capability allows manufacturers to increase throughput while maintaining the high standards required for 5G applications.

Tip: Companies like Ningbo VET Energy Technology Co., Ltd are leading the way in developing innovative EPI SUSCEPTOR solutions that support both consistency and scalability, ensuring the industry can meet future demands.

Benefits for 5G Chip Manufacturing

Cost Efficiency and Scalability

Advanced EPI susceptor technology significantly reduces production costs and enhances scalability in 5G chip manufacturing. Multi-layer coating architectures, such as those developed by Coherent Corp, extend susceptor lifespan by 40%. This improvement is critical since susceptors account for 15-20% of silicon carbide (SiC) epitaxial wafer production costs. By increasing durability, manufacturers can lower replacement frequency and operational expenses.

The growing demand for semiconductor materials further underscores the importance of cost-efficient solutions. The U.S. semiconductor materials market is projected to grow at a compound annual growth rate (CAGR) of 8.6% through 2030. This trend highlights the need for technologies that improve yield rates and reduce waste. Additionally, the electric vehicle market, expected to grow at a 25% CAGR through 2030, drives demand for SiC-based power electronics. TaC-coated susceptors play a pivotal role in meeting these requirements, ensuring scalability for high-volume production.

Enhanced Chip Performance

EPI susceptors contribute directly to the enhanced performance of 5G chips. Their ability to maintain uniform heat distribution and high material quality ensures the production of defect-free semiconductor layers. These layers exhibit superior electrical properties, such as higher carrier mobility and reduced defect density. Such improvements translate into faster data transmission and greater energy efficiency, both critical for 5G applications. By enabling consistent and reliable manufacturing processes, EPI susceptors help meet the stringent performance standards of next-generation technologies.

Contribution of Ningbo VET Energy Technology Co., Ltd

Ningbo VET Energy Technology Co., Ltd has emerged as a leader in EPI susceptor innovation. The company focuses on developing advanced solutions that optimize thermal performance, cost efficiency, and compatibility with semiconductor processes. By leveraging cutting-edge materials and engineering techniques, Ningbo VET Energy Technology Co., Ltd has set new benchmarks in the industry. Their contributions have not only improved the efficiency of epitaxial growth but also supported the scalability required for 5G chip production. These advancements position the company as a key player in the global semiconductor market.

EPI susceptors play a vital role in enhancing epitaxial growth efficiency, which directly impacts the quality of semiconductor materials required for 5G chip production. Their advanced thermal conductivity and chemical stability enable the creation of high-performance devices essential for next-generation applications. Ningbo VET Energy Technology Co., Ltd continues to lead innovation in this field, driving advancements that support the growing demand for reliable 5G technologies.

FAQ

What materials are commonly used to manufacture EPI susceptors?

EPI susceptors are typically made from graphite or silicon carbide. These materials provide excellent thermal stability and chemical resistance, ensuring reliable performance during epitaxial growth processes.

How do EPI susceptors improve 5G chip production?

EPI susceptors enhance uniform heat distribution and material quality. These improvements lead to defect-free semiconductor layers, which are essential for high-performance 5G chips.

Why is Ningbo VET Energy Technology Co., Ltd significant in this field?

Ningbo VET Energy Technology Co., Ltd drives innovation in EPI susceptor technology. Their advanced solutions optimize thermal performance, scalability, and cost efficiency for 5G chip manufacturing.

Tip: For more insights into EPI susceptors, explore Ningbo VET Energy Technology Co., Ltd’s latest advancements in epitaxial growth technology.