VET Energy uses ultra-high purity silicon carbide (SiC) formed by chemical vapor deposition (CVD) as the source material for growing SiC crystals by physical vapor transport (PVT). In PVT, the source material is loaded into a crucible and sublimated onto a seed crystal.

A high purity source is required to manufacture high quality SiC crystals.

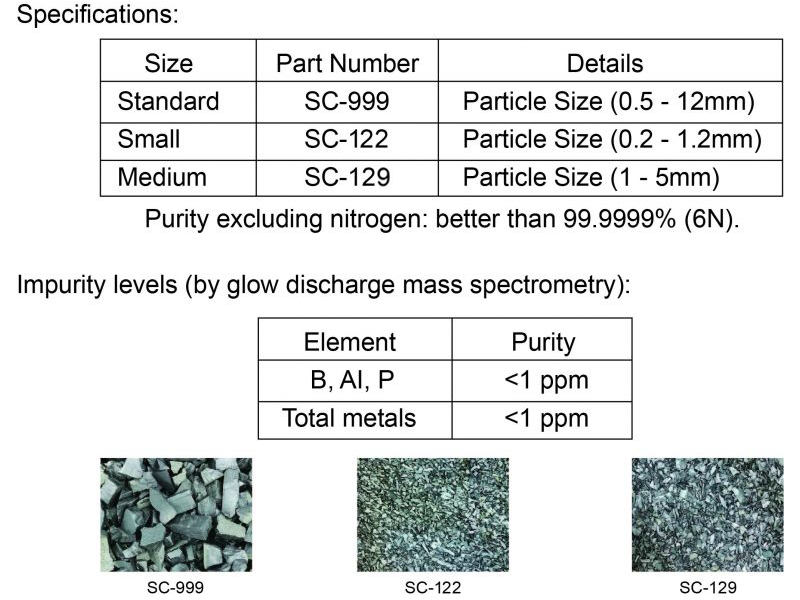

VET Energy specializes in providing large-particle SiC for PVT. It offers higher density compared to small-particle material formed by spontaneous combustion of Si and C-containing gases. Unlike solid-phase sintering or Si-C reactions, it eliminates the need for a sintering furnace or lengthy sintering steps, ensuring a consistent evaporation rate and improved run-to-run uniformity.

Introduction:

1. Prepare CVD-SiC block source: First, you need to prepare a High Purity CVD Solid SiC Bulk source, which is usually of high purity and high density. This can be prepared by chemical vapor deposition (CVD) method under appropriate reaction conditions.

2. Substrate preparation: Select an appropriate substrate as the substrate for SiC single crystal growth. Commonly used substrate materials include silicon carbide, silicon nitride, etc., which have a good match with the growing SiC single crystal.

3. Heating and sublimation: Place the CVD-SiC block source and substrate in a high-temperature furnace and provide appropriate sublimation conditions. Sublimation means that at high temperature, the block source directly changes from solid to vapor state, and then re-condenses on the substrate surface to form a single crystal.

4. Temperature control: During the sublimation process, the temperature gradient and temperature distribution need to be precisely controlled to promote the sublimation of the block source and the growth of single crystals. Appropriate temperature control can achieve ideal crystal quality and growth rate.

5. Atmosphere control: During the sublimation process, the reaction atmosphere also needs to be controlled. High-purity inert gas (such as argon) is usually used as a carrier gas to maintain appropriate pressure and purity and prevent contamination by impurities.

6. Single crystal growth: The CVD-SiC block source undergoes a vapor phase transition during the sublimation process and recondenses on the substrate surface to form a single crystal structure. Rapid growth of SiC single crystals can be achieved through appropriate sublimation conditions and temperature gradient control.

With R & D capabilities from key materials to end application products, the core and key technologies of independent intellectual property rights have achieved a number of scientific and technological innovations.