Selecting the right graphite rods for aerospace applications requires attention to grain quality, mechanical strength, and thermal resistance. Buyers should prioritize supplier credibility, such as ISO 9001 certification, to ensure long-term value. Ningbo VET Energy Technology Co., Ltd delivers certified solutions that meet demanding aerospace standards.

Key Takeaways

- Choose graphite rods with high mechanical strength, excellent thermal resistance, and low weight to ensure safety and efficiency in aerospace applications.

- Verify supplier certifications like ISO 9001:2015 and check their track record to guarantee quality, reliability, and on-time delivery.

- Focus on total cost of ownership by investing in high-quality graphite rods that reduce maintenance, replacements, and downtime over time.

Key Performance Criteria for Graphite Rods

Mechanical Strength and Durability of Graphite Rods

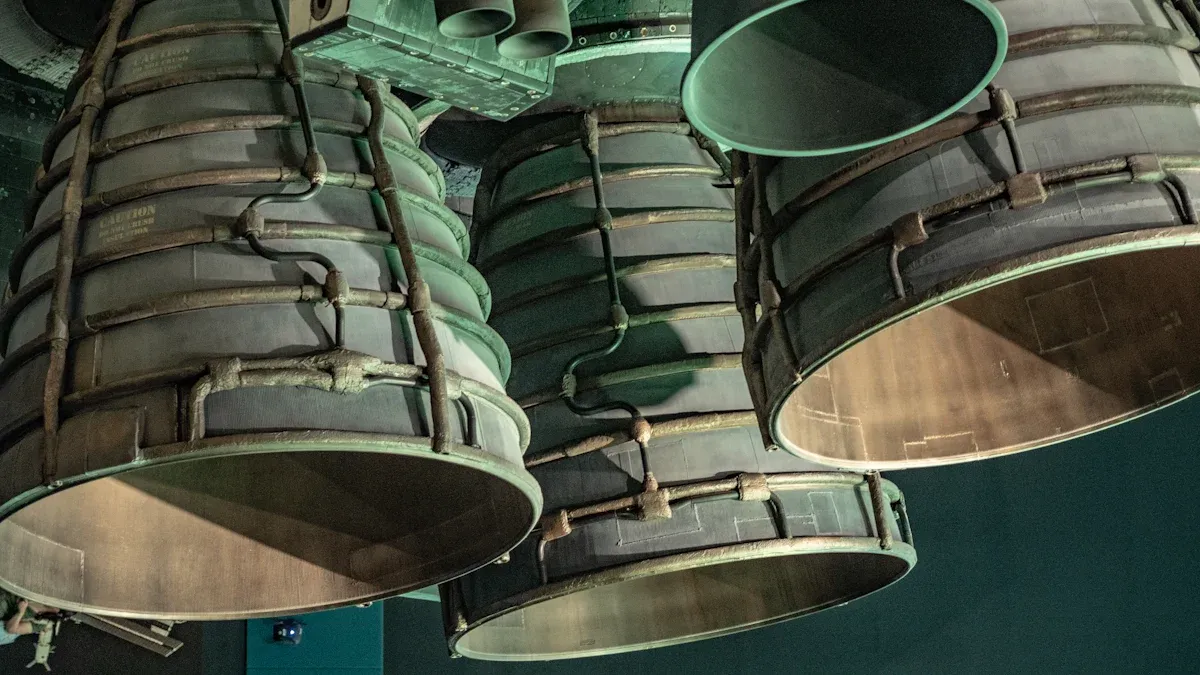

Aerospace engineers demand materials that can handle intense mechanical stress and repeated use. Graphite rods offer high compressive strength and resist wear, making them suitable for critical aerospace components. Their uniform structure ensures consistent performance under heavy loads. Isotropic graphite rods, in particular, provide strength in all directions, which helps prevent failure during launch or re-entry. Ningbo VET Energy Technology Co., Ltd supplies graphite rods that meet these strict durability standards, supporting reliable operation in demanding environments.

Thermal Stability and High-Temperature Resistance

Thermal stability is essential in aerospace, where components face extreme heat. Graphite rods excel in this area, maintaining their properties at temperatures far beyond most metals and ceramics. The following table highlights key thermal properties:

| Property | Value |

|---|---|

| Purity | ≥ 99.9% |

| Density | 1.7–1.92 g/cm³ |

| Thermal Conductivity | 100–200 W/m·K |

| Maximum Operating Temperature | Up to 3000°C (in inert atmosphere) |

Graphite rods can withstand temperatures up to 3000°C in inert or vacuum environments. This makes them ideal for rocket nozzles, heating elements, and other aerospace parts exposed to extreme heat. Unlike many metals, graphite does not melt but instead sublimates at very high temperatures, ensuring stability and safety. Aerospace manufacturers often choose graphite rods for their ability to resist thermal shock and chemical attack, especially in high-purity grades.

Note: Graphite rods maintain their structure and performance even when exposed to rapid temperature changes, which is vital for aerospace missions.

Lightweight and Density Advantages

Weight reduction is a top priority in aerospace design. Graphite rods provide a high strength-to-weight ratio, allowing engineers to build lighter structures without sacrificing durability. This weight savings leads to several benefits:

- Improved fuel efficiency, as lighter vehicles require less energy to launch and maneuver.

- Increased payload capacity, enabling spacecraft to carry more equipment or supplies.

- Enhanced range and performance, as reduced mass allows for longer missions.

The density of graphite rods, typically between 1.7 and 1.92 g/cm³, is much lower than that of metals like steel or titanium. This property helps aerospace companies meet strict weight targets while maintaining structural integrity.

Electrical and Thermal Conductivity in Aerospace

Graphite rods stand out for their excellent thermal and electrical conductivity. These properties are crucial for managing heat and electricity in aerospace systems. The table below summarizes typical conductivity values:

| Property | Typical Values / Details |

|---|---|

| Thermal Conductivity (ab plane) | Up to 4180 W/m·K (along graphene planes) |

| Thermal Conductivity (c-axis) | 5-10 W/m·K (perpendicular to graphene planes) |

| Electrical Conductivity | Inherent due to delocalized electrons |

| Aerospace Application | Heat dissipation, temperature resistance |

Graphite rods efficiently transfer heat away from sensitive electronics and structural components. Their anisotropic nature means they conduct heat much better along certain directions, which engineers use to control temperature in satellites and aircraft. The electrical conductivity of graphite rods also supports their use in sensors, batteries, and other electronic systems found in aerospace vehicles.

Tip: When selecting graphite rods for aerospace, consider both the direction and magnitude of thermal conductivity to ensure optimal heat management.

Application-Specific Graphite Rods Requirements

Graphite Rods for Structural Aerospace Components

Aerospace structures demand materials that combine strength and low weight. Graphite rods meet these needs through a high strength-to-weight ratio and excellent thermal shock resistance. Engineers select graphite for its ability to maintain shape and stability at high temperatures. The mechanical properties of graphite are anisotropic, so designers must align the rods to match load directions. Pyrolytic graphite offers enhanced hardness and dimensional stability, making it ideal for precision parts. Production factors such as grain size and orientation further improve reliability.

Graphite rods, especially when used in carbon fiber composites, outperform metals in several ways:

| Property | Graphite/Carbon Fiber Composite | Metals (e.g., mild steel) |

|---|---|---|

| Strength | Up to 5x stronger | Baseline |

| Weight | Up to 5x lighter | Baseline |

| Fatigue resistance | Superior | Inferior |

| Corrosion resistance | Better | Lower |

| Thermal stability | Maintains at high temp | Degrades at high temp |

Graphite Rods in Thermal Management Systems

Thermal management in aerospace relies on materials that can handle rapid temperature changes. Graphite rods excel due to their high thermal conductivity and resistance to thermal shock. These rods absorb and dissipate heat efficiently, protecting sensitive equipment during launch and re-entry. Isostatic graphite, with its uniform structure, is often chosen for these systems. Flexible graphite also finds use in seals and gaskets, providing both heat dissipation and resistance to thermal cycling.

Tip: Selecting the right grade ensures optimal performance and durability in harsh aerospace environments.

Graphite Rods for Electrical and Electronic Applications

Aerospace electrical systems require components with precise dimensions and reliable conductivity. Advanced machining of graphite rods allows for tight tolerances and smooth surfaces, which improve performance and lifespan. The material’s excellent electrical conductivity reduces energy loss, while its durability means fewer replacements and less downtime. Customization options let engineers design components that fit specific system needs, increasing reliability across missions.

Material Grades and Manufacturing Processes of Graphite Rods

Understanding Graphite Rods Grades and Purity

Aerospace projects require careful selection of graphite rod grades and purity levels. Each grade offers unique properties that impact performance. The table below summarizes the main grades and their key features for aerospace use:

| Graphite Grade | Purity Level (Carbon Content) | Key Properties Relevant to Aerospace Use |

|---|---|---|

| Amorphous Graphite | 60–85% | Good thermal conductivity, stable in reducing environments, wear resistance |

| Flake Graphite | 85–99% | Excellent thermal and electrical conductivity, good lubricity at high temperatures |

| Vein/Lump Graphite | 90–99% | Exceptional conductivity, superior oxidation resistance, high purity |

| Die-Molded Graphite | >99% | Chemically inert, high strength, highly machinable |

| Extruded Graphite | >99% | Anisotropic strength, good machinability |

| Isostatic Graphite | >99.99% | Ultra-high purity, isotropic, excellent conductivity, precise machinability |

| Vibration-Molded Graphite | >99% | High conductivity, durable, moderate isotropy |

| Metal-Impregnated Graphite | N/A | Enhanced conductivity, corrosion resistance, improved strength |

| Nuclear-Grade Graphite | >99% | High density, dimensional stability, low neutron absorption |

Ultra-high purity graphite rods, such as isostatic grades, deliver the reliability needed for critical aerospace components.

Production Methods Impacting Graphite Rods Performance

Manufacturers use several methods to produce aerospace-grade graphite rods. Each step influences the final properties:

- Raw materials selection: Petroleum coke or needle coke ensures high carbon content.

- Mixing: Binders like coal tar pitch help form a cohesive mixture.

- Forming: Molding, extrusion, or isostatic pressing shapes the rods.

- Baking: High temperatures harden the material and remove volatiles.

- Impregnation: Optional step to boost density and strength.

- Graphitization: Extreme heat transforms carbon into crystalline graphite.

- Machining: Precision shaping meets aerospace standards.

Isostatic pressing creates rods with uniform properties and high density, ideal for demanding aerospace applications. Consistent manufacturing ensures reliable thermal and mechanical performance.

Impurity Control in Aerospace-Grade Graphite Rods

Strict impurity control is essential for aerospace-grade graphite rods. Manufacturers begin with careful screening and pretreatment of raw materials. Chemical purification methods, such as alkali fusion and acid leaching, remove metallic contaminants. Halogen treatments and thermal purification at temperatures above 2500°C further reduce impurities. Plasma purification eliminates stubborn contaminants, while flotation techniques separate graphite from denser materials. These steps guarantee high purity and structural integrity, supporting the reliability required in aerospace environments. Ningbo VET Energy Technology Co., Ltd applies advanced impurity control to deliver graphite rods that meet the highest industry standards.

Quality Assurance and Certification for Graphite Rods

Industry Standards and Certifications for Graphite Rods

Aerospace projects require strict quality controls. Companies must follow recognized industry standards and certifications to ensure safety and performance. These standards help buyers trust the materials they receive. Common certifications and standards include:

- MIL-P Spec

- ASTM

- ASME

- AMS standards

- ISO 9001:2015 certification

- Mil-Spec

- ANSI

- AS

- AWS

- CSA

- DOT

- QS

- SAE

- TS standards

- CE certification

- NADCAP certification

- FAA approval

- FDA approval

- RoHS compliance

- NADCAP accreditation

- ITAR registration

Ningbo VET Energy Technology Co., Ltd maintains compliance with these standards. This commitment ensures that every batch of graphite rods meets the highest aerospace requirements.

Testing Protocols and Documentation Requirements

Testing protocols confirm the quality and reliability of graphite rods before use in aerospace systems. Laboratories use several ASTM standards to check important properties. The table below shows common testing methods:

| ASTM Standard | Testing Focus | Description |

|---|---|---|

| ASTM C565-15(2021) | Mechanical strength testing | Measures tension and flexural strength, uses Weibull distribution for failure analysis. |

| ASTM D7542-21 | Oxidation resistance testing | Assesses oxidation rate under controlled conditions for quality control. |

| ASTM D7779 | Fracture toughness testing | Determines resistance to crack growth at room temperature. |

| ASTM C565 (resonant frequency method) | Dynamic elastic properties | Measures Young’s modulus, shear modulus, and Poisson’s ratio using vibration tests. |

Tip: Complete documentation of test results and certifications helps buyers verify product quality and traceability.

Supplier Evaluation Checklist for Graphite Rods

Assessing Supplier Technical Expertise and Support

Buyers should look for suppliers with proven technical expertise in graphite machining. Key criteria include:

- Specialization in precision machining with tight tolerances and smooth surface finishes.

- Consistent quality from prototype to full-scale production.

- Deep knowledge of graphite materials and their machining processes.

- Experience serving demanding industries such as aerospace, power generation, and medical.

- A long-standing reputation for high-quality products and customer satisfaction.

- Capabilities in custom machining and solutions tailored to aerospace needs.

Suppliers with ISO 9001:2015 certification and Tier 1 status for aerospace projects demonstrate a commitment to quality. Their technical support can help buyers select the right graphite rods, ensuring reliable performance in critical applications.

Reviewing Supplier Track Record and References

A strong supplier track record signals reliability. Buyers should review references from other aerospace clients and check for on-time delivery records. Suppliers with over 40 years of industry experience often show deep expertise and a focus on customer satisfaction. Approved supplier status for major aerospace companies, such as Rolls Royce Nuclear Submarine plc, indicates compliance with strict standards. Consistent delivery to specification, along with conformity and origin certification, builds trust and reduces risk.

Tip: Ask for case studies or testimonials from similar aerospace projects to confirm supplier capabilities.

Evaluating Supply Chain Reliability and Company Information (Ningbo VET Energy Technology Co., Ltd)

Supply chain reliability ensures that projects stay on schedule. Buyers should confirm that suppliers offer strong customer support, innovation, and sustainability initiatives. Ningbo VET Energy Technology Co., Ltd stands out for its commitment to quality and timely delivery. The company maintains ISO 9001:2015 certification and provides full documentation for every batch. Their expertise in custom graphite rods and dedication to customer service make them a trusted partner for aerospace applications.

Cost vs. Value Considerations for Graphite Rods

Total Cost of Ownership of Graphite Rods

Aerospace companies often look beyond the initial purchase price when evaluating materials. The total cost of ownership includes several factors. These factors include installation, maintenance, replacement frequency, and downtime. High-quality graphite rods can reduce long-term expenses. They last longer and require fewer replacements. This durability helps lower maintenance costs and minimizes disruptions during missions.

A simple table can help compare the total cost of ownership:

| Factor | Low-Quality Rods | High-Quality Rods |

|---|---|---|

| Initial Cost | Low | Moderate |

| Replacement Rate | High | Low |

| Maintenance Needs | Frequent | Rare |

| Downtime Risk | High | Low |

Note: Investing in premium graphite rods from a trusted supplier like Ningbo VET Energy Technology Co., Ltd can lead to significant savings over the lifespan of aerospace equipment.

Balancing Performance and Budget in Aerospace Applications

Aerospace projects require careful budget management. Engineers must balance performance needs with cost constraints. Selecting the right graphite rods ensures both safety and value. High-performance materials may cost more upfront, but they deliver better results in critical missions. Teams should evaluate the specific requirements of each application. They can then choose rods that meet those needs without overspending.

- Review technical specifications for each project.

- Compare supplier certifications and track records.

- Consider long-term reliability over short-term savings.

Tip: Choosing the right supplier helps achieve the best balance between performance and budget.

Buyers should follow these steps to select the right graphite rods for aerospace needs:

- Match rod properties to project requirements.

- Check supplier certifications and track record.

- Focus on long-term value, not just price.

Careful supplier evaluation ensures reliable performance and safety in every aerospace mission.

FAQ

What certifications should buyers look for in aerospace graphite rods?

Buyers should check for ISO 9001:2015, ASTM, and NADCAP certifications. These ensure the rods meet strict aerospace quality and safety standards.

How does Ningbo VET Energy Technology Co., Ltd ensure product quality?

Ningbo VET Energy Technology Co., Ltd uses advanced testing, strict impurity control, and full documentation. The company maintains ISO 9001:2015 certification for every batch.

Can graphite rods be customized for unique aerospace applications?

Yes. Suppliers like Ningbo VET Energy Technology Co., Ltd offer custom machining and design support to meet specific aerospace project requirements.