Graphite plate design plays a key role in battery annealing. Engineers select the right material, adjust plate geometry, and control thickness to help heat spread evenly. Good surface area and proper arrangement improve the process. These choices lead to better battery performance and greater energy efficiency.

Key Takeaways

- Choosing high-quality graphite plates with the right thickness and purity helps spread heat evenly during battery annealing, improving battery life and performance.

- Designing graphite plates with optimal geometry and stacking methods reduces hot spots and ensures safer, more efficient heat management.

- Using simulations and careful integration with cooling systems allows engineers to create cost-effective, scalable graphite plate solutions that boost battery safety and energy efficiency.

Importance of Uniform Heat Distribution

Effects on Battery Performance and Longevity

Uniform heat distribution during battery annealing leads to significant improvements in battery quality. Researchers have observed several benefits when heat spreads evenly across battery materials:

- Annealing LiCoO₂ thin films at 600 °C for one hour increases crystallinity, which helps lithium ions move more easily.

- X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy (SEM) show that even heating creates a more uniform mix of lithium and cobalt and raises oxygen content.

- The process refines the microstructure, forming a denser top layer that interacts better with the electrolyte.

- Electrochemical tests reveal higher charge and discharge capacity after uniform annealing.

- Improved uniformity in both structure and chemistry means batteries last longer and perform better.

These results highlight the value of controlled and even heating during the annealing process.

Risks of Inconsistent Heat Management

Non-uniform heat distribution can cause serious problems in battery cells. The table below outlines the measurable effects:

| Measurable Effect | Description | Supporting Evidence |

|---|---|---|

| Accelerated degradation rate | Thermal gradients as small as 3 °C can increase degradation rates by 300%. | Experiments show positive feedback from thermal gradients accelerating degradation. |

| Non-uniform current distribution | Resistance differences lead to uneven current flow, with local C rates varying widely. | Modeling and analysis link current swapping to resistance variations. |

| Increased resistance and SEI growth | Higher local current density speeds up SEI layer growth by up to 10x. | In-situ measurements confirm SEI growth sensitivity to current density. |

| Positive feedback loop | Resistance inhomogeneity causes current inhomogeneity, worsening degradation. | Simulations show evolving resistance and current distributions. |

| Limitations of lumped models | Uniform models underestimate degradation and miss key interactions. | Comparative analysis highlights the need for spatial resolution. |

| Impact of cooling strategies | Cooling methods affect thermal gradients and degradation patterns. | 3D models reproduce observed effects of cooling on degradation. |

Note: Even small temperature differences inside a battery can lead to much faster aging and uneven performance. Careful design and control of the heating process remain essential for reliable battery operation.

Heat Transfer Fundamentals in Battery Annealing

Mechanisms of Heat Transfer

Battery annealing relies on several key heat transfer mechanisms to ensure even temperature distribution. These mechanisms include:

- Conduction: Heat moves directly through solid materials such as fins and electrode layers. Materials like aluminum and graphite help transfer heat efficiently.

- Convection: Cooling fluids, such as refrigerants or water, carry heat away from battery surfaces. Liquid cooling plates and mini-channels improve this process.

- Phase Change: Some systems use special fluids that absorb heat by changing from liquid to gas, which helps control temperature spikes.

Researchers use both experiments and computer models to study these processes. They test different cooling structures, such as L-shaped fins and liquid cold plates, to find the best designs. Simulations help engineers predict how changes in plate shape or material affect temperature uniformity. Scientists also study how the tiny structure of battery electrodes—like porosity and particle size—affects heat flow. More contact between particles means better heat transfer, while higher porosity can lower battery temperature.

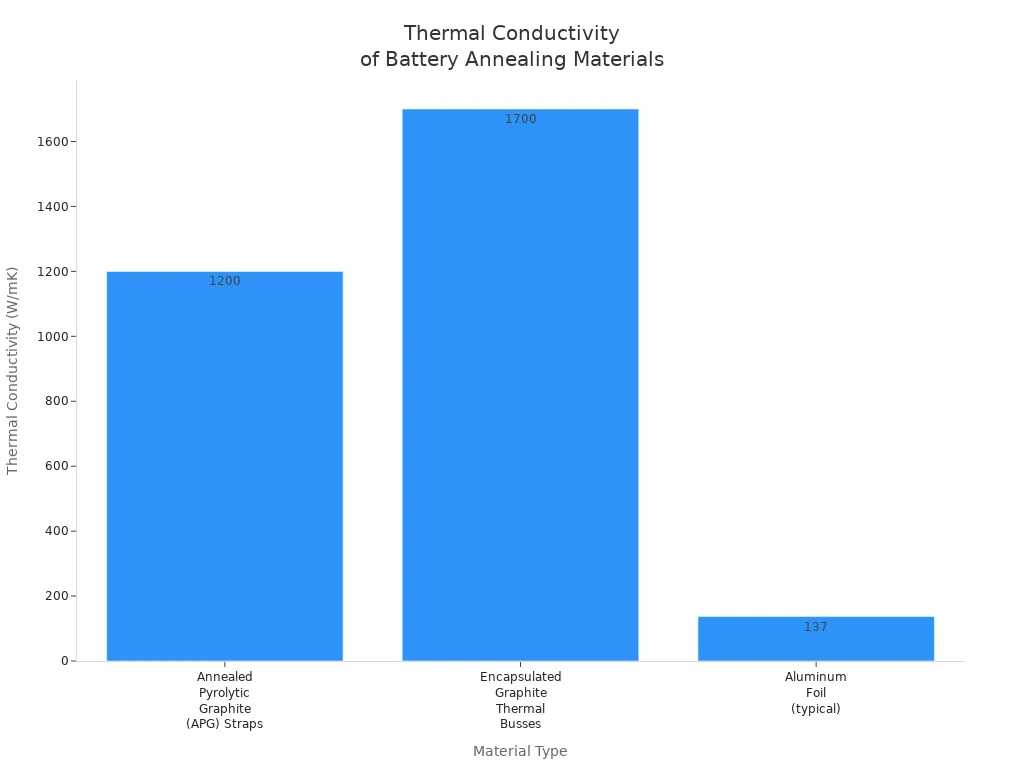

Graphite Plate Role in Thermal Management

Graphite plates play a central role in battery annealing because of their outstanding thermal properties. Compared to metals like aluminum and copper, graphite plates offer much higher thermal conductivity and lower weight. This means they spread heat more quickly and evenly, which helps prevent hot spots and improves battery safety.

| Material Type | Thermal Conductivity (W/mK) | Conductance (W/K) | Weight (lbs) | Additional Notes |

|---|---|---|---|---|

| Annealed Pyrolytic Graphite (APG) Straps | Up to 1200 | 0.82 | 0.17 | 3-5 times more conductive per unit mass than aluminum foil; 9-15 times more than copper foil; flexible and lightweight |

| Encapsulated Graphite Thermal Busses | Up to 1700 (in-plane) | N/A | N/A | Can replace solid metal solutions; tailored CTE for device matching |

| Aluminum Foil (typical) | 137 | 0.65 | 0.85 | Commonly used metal in thermal straps |

| Copper Foil (typical) | N/A | N/A | N/A | Commonly used metal in thermal straps |

Note: Graphite plates not only improve heat transfer but also reduce the overall weight of the battery system. This advantage makes them a preferred choice for modern battery annealing processes.

Graphite Plate Design Optimization

Material Selection and Purity

Selecting the right graphite material for battery annealing requires careful attention to purity and structure. High purity ensures that both organic and inorganic impurities, such as transition metals, binders, SEI films, and leftover electrolytes, are removed. Engineers restore structural integrity to reduce defects from cycling and mechanical stress. The purification process uses several steps:

- Ultrasonication-assisted gravity separation removes surface impurities.

- Controlled heat treatment brings metallic impurities to the surface.

- Acid leaching eliminates these impurities.

- Surface modification, like pyrolytic carbon coating, repairs interfacial defects and boosts electrochemical performance.

- The regenerated graphite must match the electrochemical properties of commercial LIB-grade graphite.

- Sustainable recycling methods are preferred to reduce environmental impact and energy use.

These steps help maintain high purity and structural quality, which are essential for battery performance and long life.

Plate Geometry and Dimensions

The geometry of a graphite plate affects how well it spreads heat during annealing. Thickness stands out as the most important geometric factor. Plates that are too thin, about 1 mm, cannot handle high temperatures and may fail. Plates that are too thick, around 3–4 mm, lower temperature gradients but increase resistance to heat flow, which can reduce power output. An optimal thickness of 2 mm provides the best balance between temperature uniformity and power generation. The unique structure of graphite, with high thermal conductivity in the plane of the plate and lower conductivity through the thickness, helps spread heat efficiently. Length and width do not have a major impact on heat distribution efficiency.

Thickness and Surface Area

Engineers use both simulations and experiments to study how plate thickness affects thermal uniformity. The table below shows results from optimizing the thickness of a cold plate in an optical module:

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Maximum junction temperature | 33 °C | 31.3 °C |

| Temperature difference | 2.4 °C | 1.2 °C |

Reducing the plate thickness to an optimal value lowers the maximum temperature and cuts the temperature difference in half. This improvement means better heat distribution and less risk of hot spots. Engineers confirm these results with both computer models and real-world tests.

Tip: Adjusting the thickness of the graphite plate can make a big difference in how evenly heat spreads during battery annealing.

Plate Arrangement and Stacking

The way engineers arrange and stack graphite plates can greatly improve heat distribution. Best practices include:

- Tailoring the orientation of graphite or carbon fiber scaffolds, such as using a “Tetris-Style Stacking Process,” aligns thermal pathways and boosts heat dissipation.

- Using multilayered or bidirectional tuning methods optimizes how heat moves through the material.

- Building highly-oriented graphite monoliths aligns the layers for better overall thermal conductivity.

- Adding functional fillers in selected layers creates efficient pathways for heat to travel.

- Focusing on material orientation, multilayer stacking, and composite structuring maximizes heat transfer in graphite plate assemblies.

These strategies help engineers design graphite plate systems that deliver efficient and uniform heat management for battery annealing.

Graphite Plate vs. Alternative Materials

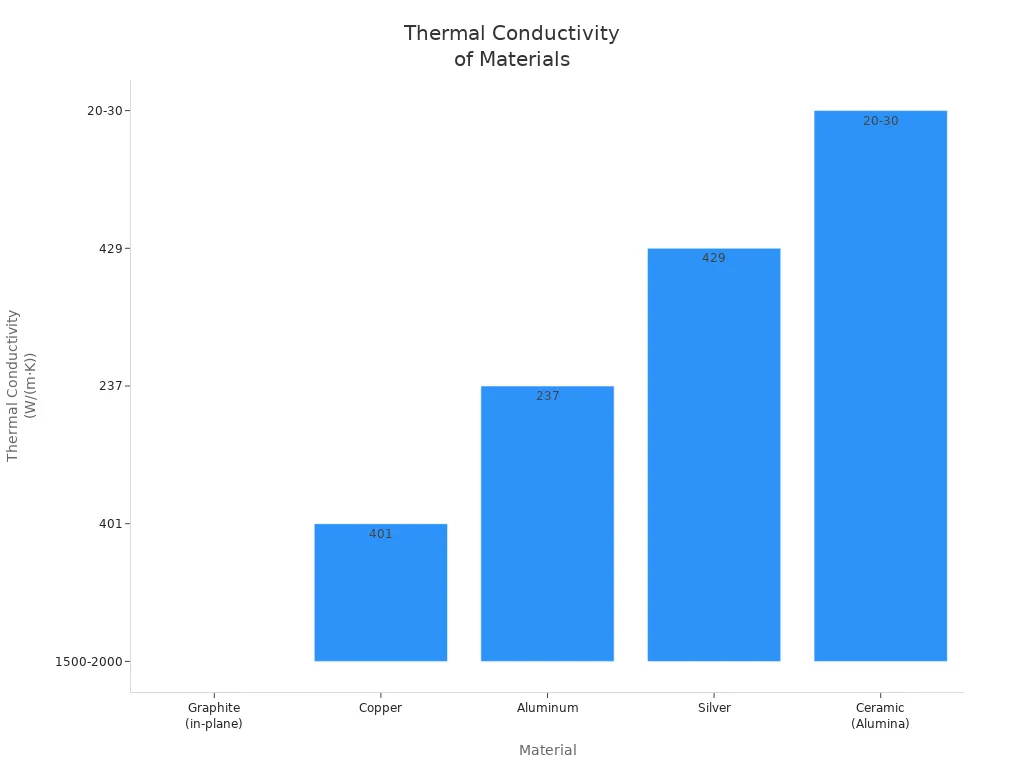

Thermal Conductivity and Efficiency

Thermal conductivity plays a critical role in battery annealing. Materials with higher conductivity spread heat more quickly, reducing the risk of hot spots. Graphite plates stand out for their exceptional in-plane thermal conductivity, which can reach up to 2000 W/(m·K). This value far exceeds that of metals like copper and aluminum, as well as ceramics such as alumina.

| Material | Thermal Conductivity (W/(m·K)) | Key Characteristics |

|---|---|---|

| Graphite (in-plane) | 1500-2000 | Very high anisotropic conductivity, excellent heat transfer in-plane |

| Copper | 401 | Isotropic, good thermal and electrical conductor |

| Aluminum | 237 | Low density, good corrosion resistance |

| Silver | 429 | High thermal and electrical conductivity |

| Ceramic (Alumina) | 20-30 | Low thermal conductivity, acts as thermal insulator |

Graphite plates outperform most alternatives in heat transfer efficiency, especially when heat must move quickly across a surface.

Durability and Chemical Resistance

Durability and chemical resistance determine how well a material performs in harsh environments. Flexible graphite resists a wide range of chemicals, from acids to bases, and tolerates extreme temperatures. It remains stable from -400°F up to 850°F in air, and even higher in steam or inert atmospheres. Low porosity and high mechanical strength help graphite plates last longer under pressure and repeated use.

| Material | Durability & Chemical Resistance Characteristics | Limitations & Applications |

|---|---|---|

| Silicon Carbide | Exceptional thermal conductivity, thermal shock resistance, chemical resistance | Higher cost, limited shapes; used in foundries, metal casting, chemical processes |

| Clay-Graphite | Good thermal shock resistance, moderate durability | Lower thermal conductivity, limited chemical resistance |

| Platinum | Exceptional corrosion resistance, high melting point | Extremely high cost, limited mechanical strength |

| Nickel | Oxidation resistance, good thermal conductivity | Susceptible to acidic corrosion, lower melting point |

| Tungsten | Highest melting point, thermal shock resistance, high density | Very high cost, difficult machining |

Note: Graphite plates maintain flexibility and sealing ability even after millions of compression cycles, making them reliable for repeated thermal cycling.

Cost and Supply Considerations

Cost and supply influence material choice in large-scale battery production. Graphite plates offer a balance between performance and affordability. While metals like copper and silver provide good conductivity, their higher cost and weight can limit use. Ceramics and specialty metals such as platinum or tungsten often cost much more and present machining challenges. Graphite plates, especially those made from isostatic pressed or impregnated grades, remain widely available and cost-effective for most battery annealing applications.

Simulation and Modeling for Graphite Plate Design

Finite Element Analysis (FEA)

Engineers use finite element analysis (FEA) to improve the design of graphite plates for battery annealing. FEA helps them understand how heat moves through materials with complex properties. Graphite shows highly anisotropic thermal conductivity. This means heat travels much faster along the plane of the plate than through its thickness—sometimes over 100 times faster. Standard modeling methods often fail to capture this difference. Engineers must create special mesh designs that focus on the unique structure of graphite. They adjust the size and shape of elements near heat sources and sometimes magnify the thickness direction to see small temperature changes. These steps help the model show accurate temperature gradients and heat flow.

FEA also allows engineers to build detailed 3D models. They include not only the graphite plate but also encapsulant materials, heat sources, and cooling parts. By simulating heat flux and surface convection, the model can predict how the plate will perform in real-world conditions. In one study, FEA results matched experimental data, confirming a thermal conductivity of 540 W/mK for a graphite composite—much higher than aluminum. This close match gives engineers confidence to use FEA for future designs.

Advanced Predictive Modeling Techniques

Modern engineers use advanced predictive modeling to make better design choices. These techniques include machine learning and data-driven simulations. By analyzing large sets of test data, models can predict how changes in plate geometry or material will affect heat distribution. Some teams use digital twins—virtual copies of real systems—to test new ideas before building them. These tools help engineers find the best design faster and with fewer physical prototypes.

Tip: Simulation and modeling save time and resources by allowing engineers to test many design options virtually before making final choices.

Practical Strategies for Graphite Plate Implementation

Manufacturability and Scalability

Manufacturers must consider both ease of production and the ability to scale up when designing graphite plates for battery annealing. Automated cutting and pressing methods allow for precise shaping and consistent quality. Advanced molding techniques help create plates with complex geometries. Factories can increase output by using modular production lines. Quality control systems check for defects and ensure each plate meets strict standards. These steps support large-scale manufacturing and help companies meet growing demand.

Integration with Battery Systems

Engineers use several strategies to ensure optimal thermal contact between graphite plates and battery systems:

- Thermal interface materials (TIMs) such as gap fillers, thermal pastes, flexible graphite sheets, and thermally conductive adhesives or tapes fill gaps between battery cells and cooling plates. TIMs conform to uneven surfaces and remove air pockets, which lowers thermal resistance and improves heat transfer.

- TIMs are placed at critical points to minimize temperature gradients and prevent overheating.

- In some designs, TIMs replace mechanical fasteners, which improves both thermal conduction and system integration.

- When embedding battery packs into a chassis, precise thermal and mechanical coupling keeps thermal performance reliable.

- Engineers may combine phase change materials with cold plates to even out temperatures and boost cooling efficiency.

- Structural changes, such as adding more inlet channels or optimizing cold plate design, help keep battery temperatures uniform.

- Micro-channel liquid cooling inside phase change materials further improves temperature control.

- Adjusting the distribution of expanded graphite in phase change materials reduces temperature differences across the battery.

- Using double-sided cold plates and arranging multiple plates in an optimized way lowers battery temperature and improves uniformity.

- Lightweight flame retardant materials can replace some phase change materials, reducing system weight while keeping cooling performance high.

Note: Careful integration of graphite plates and cooling systems helps batteries run safely and efficiently.

Cost-Effectiveness and Lifecycle Management

Companies look for ways to keep costs low while maintaining high performance. Graphite plates offer a good balance between price and function. Automated production and modular designs reduce labor costs. Long-lasting materials mean fewer replacements and less downtime. Recycling programs recover valuable graphite from used plates, which supports sustainability and lowers material expenses. Regular inspections and maintenance extend the life of both the plates and the battery system.

Optimizing plate design ensures batteries heat evenly and work safely. Engineers select high-quality materials and use precise shapes. They rely on digital tools and expert advice. Future trends include:

- Growth in thermally annealed pyrolytic graphite markets

- More automation and digital transformation

- AI-driven product customization and advanced thermal mapping

- Stronger focus on sustainability and energy efficiency

FAQ

What makes graphite plates better than metal plates for heat distribution?

Graphite plates provide higher thermal conductivity and lower weight. They spread heat more evenly than most metals. This helps batteries work safely and last longer.

How does plate thickness affect battery annealing?

Plate thickness controls how well heat spreads. Thin plates may fail at high temperatures. Thick plates can slow heat flow. Engineers choose an optimal thickness for best results.

Can engineers recycle graphite plates after use?

Yes, engineers can recycle graphite plates. They use purification and surface treatments to restore quality. Recycling supports sustainability and reduces material costs.