Carbon Fiber Composites (C/C) are a new generation of brake materials, replacing metal-based composites due to their exceptional mechanical, thermal, and friction properties.

Key features include:

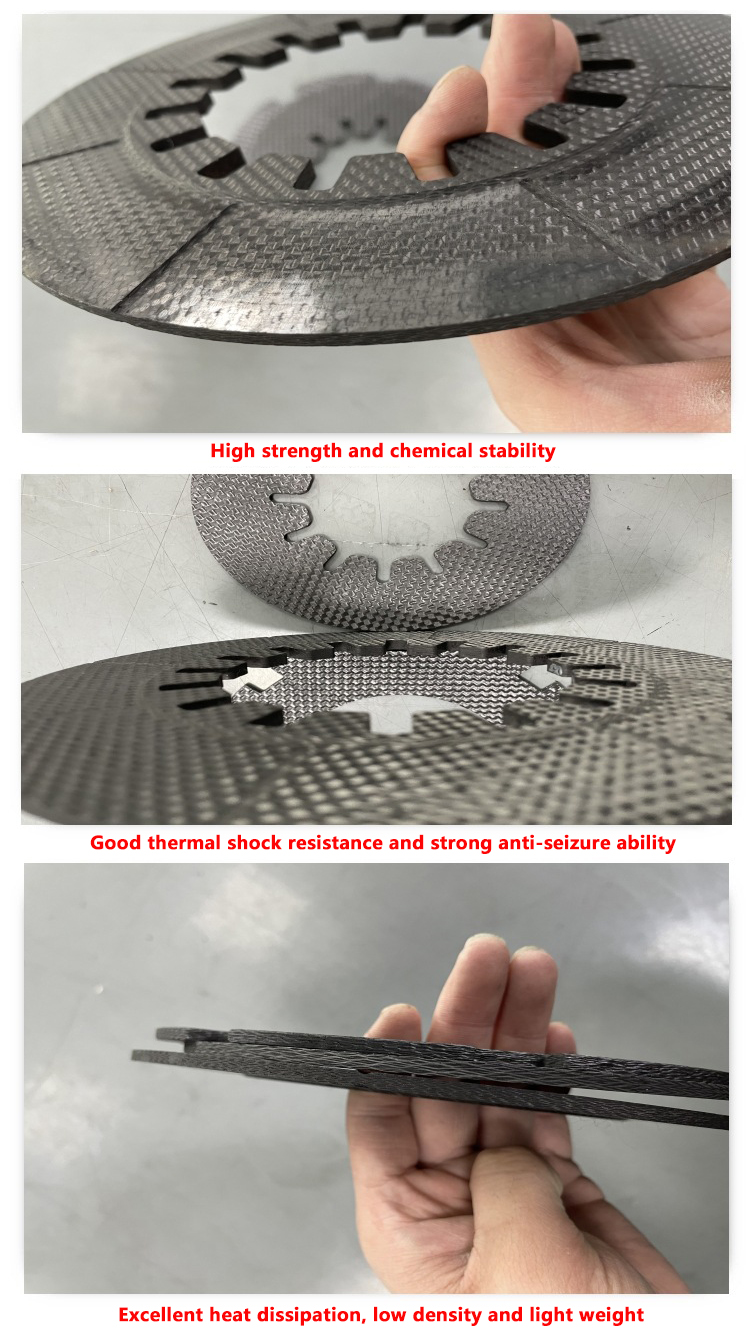

- Low density (1.5g/cm³), reducing brake disc mass.

- Superior wear resistance, lasting twice as long as metal composites.

- Stable dynamic friction, excellent anti-sticking and anti-adhesion.

- Simplified design without additional components like friction linings.

- Small thermal expansion, high specific heat capacity, and thermal conductivity.

- High working temperature and heat resistance up to 2700℃.