Aerospace components are subjected to extreme conditions, such as high temperatures and corrosive environments, making protection essential for optimal performance and safety. CVD TAC Coating provides outstanding durability and resilience to meet these demands. Advanced solutions like CVD SIC COATING and TAC COATING are revolutionizing aerospace protection, improving reliability and significantly extending the lifespan of critical components.

Key Takeaways

- CVD TAC Coating makes aerospace parts stronger and longer-lasting. It protects them from damage, rust, and very high or low heat.

- Manufacturers can adjust CVD methods to fit aerospace needs. This boosts how well parts work and cuts down on wasted materials.

- New methods like Laser-Assisted CVD apply coatings carefully to tricky shapes. This gives the best protection for detailed aerospace pieces.

The Role of CVD in Aerospace Applications

Overview of Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is a sophisticated process used to create thin, high-performance coatings on various materials. This technique involves the chemical reaction of gaseous precursors, which deposit a solid material onto a substrate. The process occurs in a controlled environment, ensuring precision and uniformity. CVD is widely recognized for its ability to produce coatings with exceptional adhesion and purity, making it a preferred choice in industries requiring advanced material performance, such as aerospace.

Benefits of CVD for Aerospace Component Protection

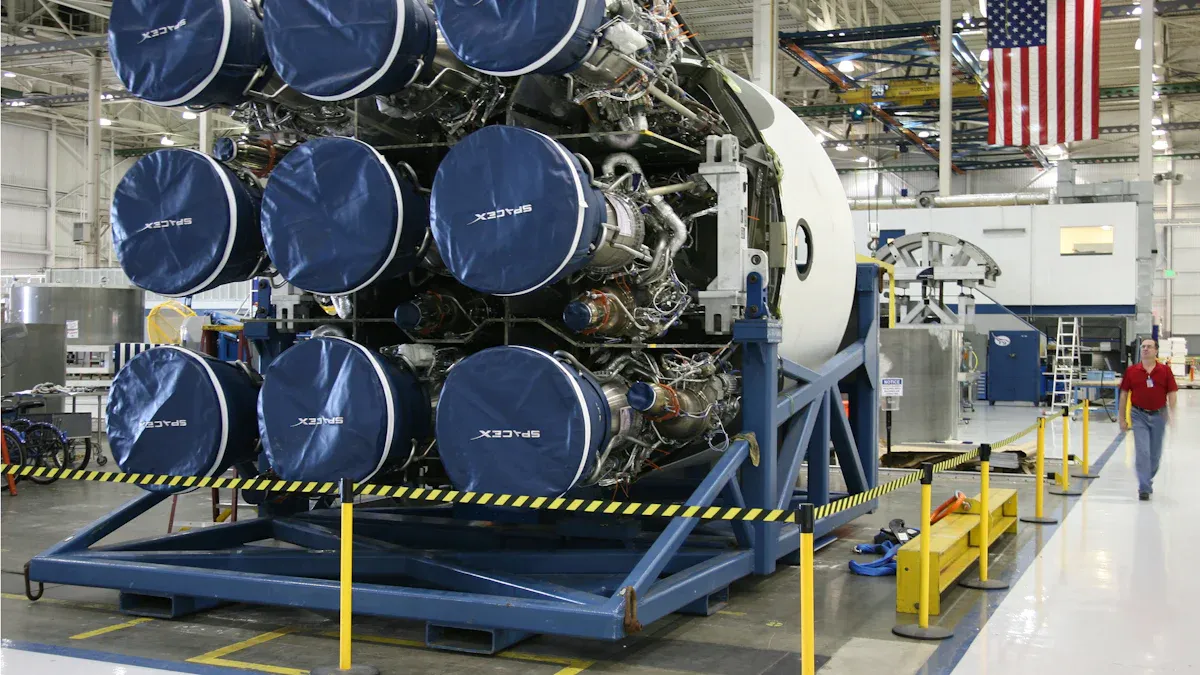

CVD offers numerous advantages for protecting aerospace components. It provides coatings with superior hardness, corrosion resistance, and thermal stability. These properties are essential for components exposed to extreme conditions, such as high temperatures and aggressive chemical environments. Additionally, CVD enables the application of materials like CVD TAC Coating, which enhances the durability and reliability of critical parts. The process ensures consistent coating thickness, reducing the risk of weak points that could compromise performance.

Why CVD Is Essential for High-Performance Coatings

The aerospace industry demands coatings that can withstand harsh operational environments while maintaining structural integrity. CVD meets these requirements by delivering coatings with unmatched precision and performance. For example, CVD TAC Coating offers exceptional resistance to wear and oxidation, ensuring long-term protection for vital components. By utilizing CVD, manufacturers can achieve coatings that not only extend the lifespan of parts but also improve overall system efficiency and safety.

Properties and Advantages of CVD TAC Coatings

Key Features of Tantalum Aluminum Carbide (TAC) Coatings

Tantalum Aluminum Carbide (TAC) coatings exhibit a unique combination of properties that make them indispensable in aerospace applications. These coatings offer exceptional hardness, which protects components from wear and mechanical damage. Their chemical stability ensures resistance to oxidation and corrosion, even in highly reactive environments. TAC coatings also possess excellent electrical conductivity, making them suitable for components requiring both mechanical and electrical performance.

Another notable feature is their ability to form a dense, uniform layer through the CVD process. This uniformity eliminates weak points, ensuring consistent protection across the entire surface. These characteristics make CVD TAC Coating a preferred choice for safeguarding critical aerospace parts.

Thermal Resistance and Durability in Aerospace Applications

Aerospace components often operate under extreme thermal conditions, where conventional materials fail. TAC coatings excel in such environments due to their remarkable thermal resistance. They can withstand temperatures exceeding 2000°C without degrading, ensuring the structural integrity of components. This property is particularly valuable for turbine blades, exhaust systems, and other high-temperature parts.

Durability is another key advantage. TAC coatings resist cracking and delamination, even under thermal cycling. This resilience reduces maintenance requirements and enhances the reliability of aerospace systems. By applying CVD TAC Coating, manufacturers can ensure that components perform reliably over extended periods, even in the harshest conditions.

Enhancing Longevity and Performance of Critical Components

The application of TAC coatings significantly extends the lifespan of aerospace components. Their wear resistance minimizes material loss, while their corrosion resistance prevents chemical damage. These properties reduce the likelihood of component failure, enhancing overall system performance.

Moreover, TAC coatings contribute to weight reduction. By enabling the use of lightweight substrates with protective coatings, they help improve fuel efficiency and reduce operational costs. This dual benefit of longevity and performance optimization underscores the value of CVD TAC Coating in modern aerospace engineering.

Tip: Ningbo VET Energy Technology Co., Ltd specializes in advanced CVD TAC Coating solutions, offering tailored applications to meet the stringent demands of the aerospace industry.

Innovative Techniques for Applying CVD TAC Coatings

Advancements in CVD Technology for Aerospace Needs

Chemical Vapor Deposition (CVD) technology has evolved significantly to meet the stringent demands of aerospace applications. Modern advancements focus on enhancing coating precision, improving deposition rates, and expanding material compatibility. These innovations allow manufacturers to apply coatings like CVD TAC Coating with greater efficiency and reliability.

One notable development is the integration of automated systems in CVD processes. Automation ensures consistent quality by reducing human error and optimizing operational parameters. Additionally, advancements in precursor materials have enabled the deposition of coatings with superior thermal and mechanical properties. These improvements address the challenges posed by extreme aerospace environments, ensuring components remain protected under high stress.

Note: Ningbo VET Energy Technology Co., Ltd leverages cutting-edge CVD technology to deliver tailored solutions for aerospace applications, ensuring unmatched performance and durability.

Customization and Precision in Coating Applications

Customization plays a pivotal role in aerospace coating applications. Each component requires a specific coating thickness, material composition, and deposition method to achieve optimal performance. CVD technology excels in delivering this level of precision.

Manufacturers can adjust deposition parameters, such as temperature, pressure, and precursor concentration, to create coatings tailored to individual component needs. For example, turbine blades may require thicker coatings for enhanced thermal resistance, while electrical connectors benefit from thinner layers with high conductivity.

The ability to customize coatings ensures compatibility with diverse aerospace materials, including titanium alloys and composite substrates. This precision minimizes waste, reduces production costs, and enhances the overall efficiency of aerospace systems.

Emerging Methods, Including Laser-Assisted CVD (LCVD)

Emerging methods like Laser-Assisted Chemical Vapor Deposition (LCVD) are transforming the application of CVD TAC Coating. LCVD uses focused laser beams to heat specific areas of a substrate, enabling localized deposition with unparalleled accuracy.

This technique offers several advantages:

- Enhanced Precision: LCVD allows manufacturers to target intricate geometries and complex surfaces, ensuring uniform coating application.

- Reduced Energy Consumption: By heating only the required areas, LCVD minimizes energy usage compared to traditional CVD methods.

- Improved Material Properties: The localized heating process enhances the adhesion and density of the deposited coating, resulting in superior performance.

LCVD is particularly beneficial for components with intricate designs, such as sensors and microelectromechanical systems (MEMS). As this technology continues to advance, it promises to redefine the standards of aerospace coating applications.

Overcoming Challenges in CVD TAC Coating Implementation

Addressing Safety and Environmental Concerns

Safety and environmental considerations play a crucial role in aerospace coating processes. Manufacturers must ensure that the chemical precursors used in CVD do not pose risks to workers or the environment. Proper ventilation systems and containment measures prevent exposure to harmful gases during deposition.

Environmental sustainability has become a priority in aerospace manufacturing. Companies are adopting eco-friendly practices, such as recycling unused precursor materials and minimizing waste. Advanced filtration systems reduce emissions, ensuring compliance with environmental regulations. These measures demonstrate the industry’s commitment to safety and sustainability.

Note: Ningbo VET Energy Technology Co., Ltd implements stringent safety protocols and environmentally responsible practices in its CVD coating processes.

Ensuring Compatibility with Aerospace Materials

Aerospace components consist of diverse materials, including titanium alloys, composites, and ceramics. Coating compatibility ensures optimal adhesion and performance. Manufacturers tailor deposition parameters to match the thermal and mechanical properties of each substrate.

Material testing plays a vital role in ensuring compatibility. Engineers evaluate factors like thermal expansion and chemical reactivity to prevent coating delamination or degradation. This meticulous approach guarantees that CVD TAC Coating performs reliably across various aerospace applications.

Balancing Cost-Effectiveness with Performance Demands

Cost-effectiveness remains a challenge in implementing advanced coatings. Manufacturers must balance the expense of high-quality precursors and sophisticated equipment with the performance benefits of CVD TAC Coating.

Process optimization reduces costs without compromising quality. Techniques like automated deposition and efficient precursor utilization enhance productivity. These advancements make high-performance coatings accessible to a broader range of aerospace applications.

Tip: Ningbo VET Energy Technology Co., Ltd offers cost-effective solutions tailored to meet the performance demands of aerospace clients.

CVD TAC Coating has revolutionized aerospace protection by delivering unmatched durability and performance. Innovation continues to refine coating techniques, ensuring precision and efficiency. Future advancements promise even greater potential, with ongoing research driving new applications and industry-wide impacts. These coatings remain essential for safeguarding aerospace components in extreme environments.

FAQ

What makes CVD TAC coatings ideal for aerospace applications?

CVD TAC coatings offer exceptional thermal resistance, durability, and wear protection, ensuring reliable performance in extreme aerospace environments.

How does Ningbo VET Energy Technology Co., Ltd ensure coating quality?

The company uses advanced CVD techniques, automated systems, and rigorous testing to deliver high-performance coatings tailored to aerospace needs.

Can CVD TAC coatings be applied to complex geometries?

Yes, emerging methods like Laser-Assisted CVD enable precise application on intricate surfaces, ensuring uniform coverage and optimal protection.