VET enregy offer Contiguous Wafer Boat base on semiconductor SIC and ceramic material. The special continuous structure design of the wafer boat ensures each wafer is tightly connected without gaps, maximizing space utilization and improving production efficiency. Precisely designed positioning holes ensure perfect alignment with fixtures during processing, enhancing accuracy and yield. Made of smooth, inert materials, the wafer boat prevents contamination, absorbs vibrations, and protects wafers during transport.

Our State-Of-The-Art Manufacturing Facilities Offer:

• Ultra-high-purity recrystallized and CVD silicon carbides

• Advanced forming and casting technologies

• Extreme-precision CNC machining

• High-temperature firing capabilities

• Plasma coating technologies

• Advanced cleaning processes

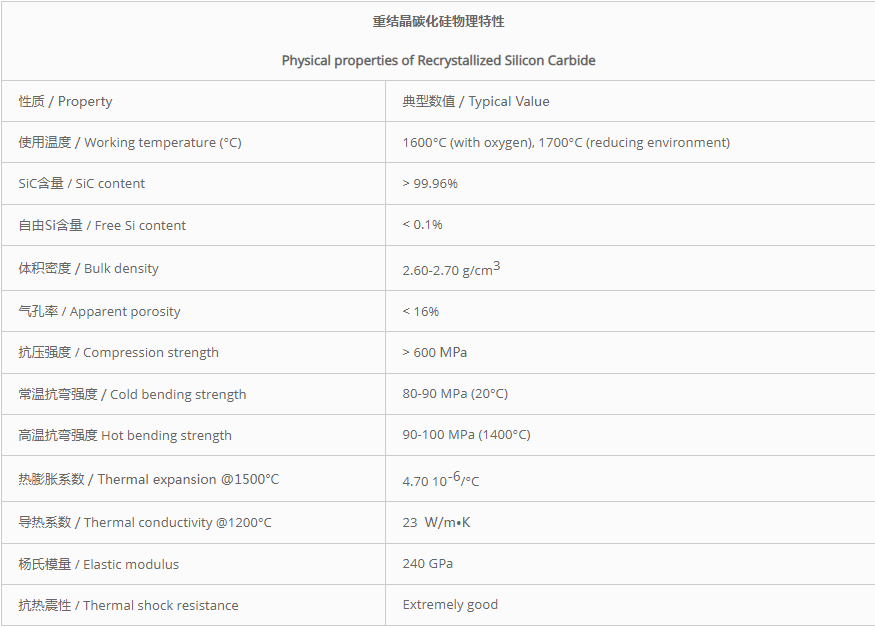

Basic physical properties of Horizontal SiC Wafer Carrier:

Advanced Material Research & Development

VET energy continues to make signficant investments in research and development to develop next-generation materials for the critical challenges faced by semiconductor and solar manufacturing industries.

As a leading manufacturer and supplier of advanced coating materials in China’s semiconductor industry, VeT energy is committed to providing customers with various customized advanced technology and product solutions.We sincerely hope to become your long-term partner in China.