Tac Coating represents a groundbreaking innovation in the field of composite material protection. Traditional metallization techniques frequently fall short in meeting the rigorous demands of contemporary industries, especially in scenarios requiring both high durability and lightweight properties. By utilizing advanced methods such as CVD TAC COATING and SIC COATING, this cutting-edge solution delivers exceptional performance. Its applications extend across aerospace, automotive, and renewable energy sectors, where CVD SIC COATING significantly boosts material resilience.

Tiras de Chaves

- Tic-Tac Coatings are tougher and last longer than metal layers. They work well for industries like airplanes and cars.

- These coatings are light, helping materials stay strong without getting heavier. This helps save fuel and cut pollution.

- Tic-Tac Coatings can be changed to fit different uses. They work best in areas like green energy, cars, and airplanes.

Limitations of Metallization

Common Metallization Methods

Traditional metallization techniques have long been used to enhance the surface properties of materials. Common methods include vapor deposition, thermal spraying, and electroplating. Each of these processes has unique applications but also significant drawbacks.

- Vapor deposition, such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), requires vacuum chambers. These chambers limit the size of workpieces and increase costs due to slow processing times.

- Thermal spray methods, while versatile, often expose materials to high temperatures. This can lead to thermal degradation or distortion, especially in polymer-based composites.

- Electroplating, though widely used, struggles with achieving uniform coatings on complex geometries. It also generates hazardous waste, raising environmental concerns.

These limitations highlight the need for alternative solutions that address the shortcomings of traditional metallization.

Challenges in Composite Applications

Applying metallization to composite materials presents additional challenges. Composites, particularly those with non-metallic substrates like polymers, often suffer from poor adhesion during the coating process. This issue arises because traditional methods are not optimized for bonding with such materials.

Environmental factors further complicate the process. High humidity can extend pumpdown cycles in vacuum chambers, while dust particles can settle on parts, causing defects. Proper part design is also critical. Large flat surfaces and deep cavities tend to amplify coating imperfections, leading to subpar results.

- To improve coating quality:

- Avoid large flat areas to minimize visible defects.

- Reduce deep cavities to ensure even coverage.

- Design surfaces perpendicular to the evaporant path for better adhesion.

Despite these efforts, metallization often falls short in meeting the durability and sustainability demands of modern industries. This underscores the importance of exploring innovative alternatives like Tic-Tac Coating.

Introduction to Tic-Tac Coating Techniques

What Are Tic-Tac Coatings?

Tic-Tac Coatings represent a transformative advancement in material protection technology. These coatings are engineered to enhance the surface properties of composite materials, offering superior durability, wear resistance, and thermal stability. Unlike traditional metallization methods, Tic-Tac Coatings incorporate advanced materials like titanium carbide (TiC) to create a robust protective layer. This innovation addresses the limitations of conventional techniques, particularly in applications requiring lightweight yet resilient solutions.

The versatility of Tic-Tac Coatings makes them suitable for a wide range of industries. Aerospace, automotive, and renewable energy sectors benefit significantly from their application. For instance, in aerospace, these coatings improve the performance of composite components exposed to extreme conditions. In automotive manufacturing, they contribute to lightweight designs without compromising strength. Renewable energy systems, such as wind turbines, also rely on these coatings to withstand harsh environmental factors.

Mechanism of Tic-Tac Coating

The effectiveness of Tic-Tac Coatings lies in their unique mechanism. These coatings utilize a deposição química de vapor (CVD) process to deposit a thin, uniform layer of titanium carbide onto the substrate. This process occurs at high temperatures, allowing the TiC particles to bond strongly with the composite material. The result is a coating that not only enhances surface hardness but also provides exceptional resistance to wear and corrosion.

Empirical data highlights the superior performance of Tic-Tac Coatings compared to non-TiC alternatives. The table below illustrates the differences in wear rate, friction coefficient, and temperature tolerance:

| Tipo de revestimento | Temperature (°C) | Wear Rate (mm³/Nm) | Coeficiente de fricção | Performance Notes |

|---|---|---|---|---|

| CT8 | 400 | Lowest | Baixo | Moderate hardness and TiC content provide satisfactory tribological performance |

| TiC Coated | 25-800 | 10⁻⁵ | Higher than non-TiC | Enhanced wear resistance due to TiC incorporation |

| Non-TiC | 25-800 | Mais alto | Mais alto | Lower wear resistance compared to TiC coatings |

The table demonstrates that TiC-based coatings outperform non-TiC coatings in wear resistance and friction management. For example, the CT8 coating, with its moderate hardness and TiC content, delivers excellent tribological performance at 400°C. Similarly, TiC-coated materials exhibit a significantly lower wear rate, even under extreme temperature conditions ranging from 25°C to 800°C.

By leveraging these properties, Tic-Tac Coatings ensure long-lasting protection for composite materials. Their ability to maintain performance across a wide temperature range makes them indispensable in demanding industrial environments. This innovative approach not only extends the lifespan of materials but also reduces maintenance costs, further solidifying its value in modern applications.

Advantages of Tic-Tac Coatings

Durabilidade Melhorada

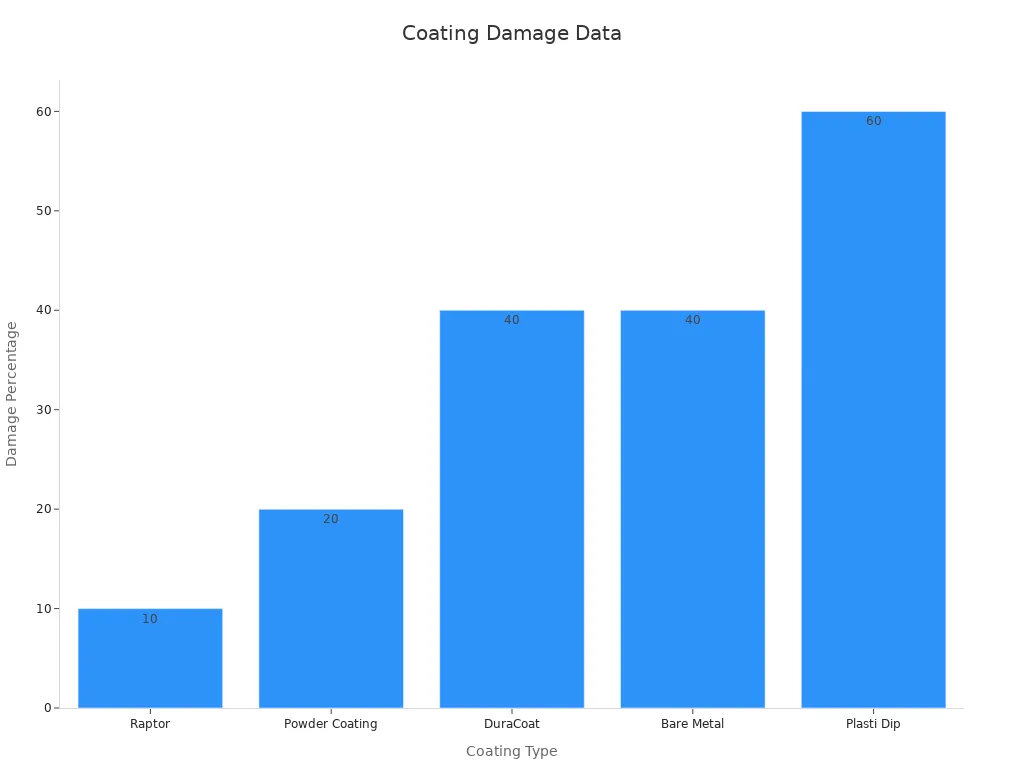

Tic-Tac Coatings provide unmatched durability, making them a superior choice for protecting composite materials. Their advanced composition, including titanium carbide, creates a robust barrier against wear, corrosion, and environmental damage. Laboratory tests validate their exceptional performance compared to traditional alternatives. For instance, a study measuring damage percentages across various coating types revealed the following results:

| Tipo de revestimento | Damage Percentage |

|---|---|

| Raptor | 10% |

| Powder Coating | 20% |

| DuraCoat | 40% |

| Bare Metal | 40% |

| Plasti Dip | 60% |

The table highlights that Tic-Tac Coatings, represented by Raptor, exhibit the lowest damage percentage, outperforming other coatings by a significant margin. This durability ensures long-lasting protection, reducing maintenance costs and extending the lifespan of materials.

Additionally, the coatings maintain their integrity under extreme conditions, such as high temperatures and abrasive environments. This resilience makes them indispensable in industries like aerospace and automotive, where materials face constant stress.

Dica: Investing in durable coatings like Tic-Tac Coatings can significantly reduce operational downtime caused by material failure.

Lightweight Design

One of the standout features of Tic-Tac Coatings is their ability to enhance material performance without adding unnecessary weight. Unlike traditional metallization methods, which often increase the overall mass of components, these coatings maintain a lightweight profile. This characteristic is particularly valuable in industries where weight reduction directly impacts efficiency and performance.

For example, in aerospace applications, reducing the weight of components can improve fuel efficiency and payload capacity. Similarly, in automotive manufacturing, lightweight designs contribute to better mileage and reduced emissions. Tic-Tac Coatings achieve this balance by forming a thin yet highly effective protective layer, ensuring that materials remain both strong and lightweight.

This innovation aligns with the growing demand for sustainable solutions in modern industries. By minimizing material weight while maximizing durability, Tic-Tac Coatings support eco-friendly practices and energy efficiency.

Versatility Across Industries

Tic-Tac Coatings demonstrate remarkable versatility, making them suitable for a wide range of applications. Their unique properties, such as high thermal stability and wear resistance, allow them to meet the diverse needs of industries like aerospace, automotive, and renewable energy.

The growing demand for these coatings is reflected in market trends. The TAC Film Market, for instance, is projected to grow from USD 5.8 billion in 2023 to USD 9.2 billion by 2033, with a compound annual growth rate (CAGR) of 4.7%. This growth highlights the increasing adoption of TAC films in various sectors. Key factors driving this demand include:

- High light transmittance and low birefringence, which make these coatings ideal for LCD technology.

- Great curling characteristics, enabling their use in flexible and high-performance displays for smartphones and televisions.

In renewable energy, Tic-Tac Coatings protect wind turbine blades from harsh environmental conditions, ensuring consistent performance. In automotive manufacturing, they enhance the durability of lightweight components, supporting the industry’s shift toward electric vehicles. This adaptability underscores the transformative potential of Tic-Tac Coatings across multiple sectors.

Applications of Tic-Tac Coating in Composite Material Protection

Aplicações Aeroespaciais

Tic-Tac Coating has revolutionized the aerospace industry by enhancing the performance and longevity of composite materials. Aircraft components, such as turbine blades and fuselage panels, often face extreme conditions, including high temperatures, pressure fluctuations, and abrasive environments. The advanced properties of this coating, particularly its thermal stability and wear resistance, ensure that these components maintain their structural integrity. By reducing material degradation, the coating minimizes maintenance requirements and extends the operational lifespan of aerospace equipment. This innovation supports the industry’s demand for lightweight yet durable solutions, improving fuel efficiency and overall performance.

Automotive Innovations

In the automotive sector, Tic-Tac Coating plays a pivotal role in advancing lightweight designs without compromising durability. Modern vehicles increasingly rely on composite materials to reduce weight and improve energy efficiency. This coating provides a robust protective layer that resists wear, corrosion, and environmental damage. Electric vehicles, in particular, benefit from this technology, as it enhances the durability of battery enclosures and lightweight chassis components. By integrating this coating, manufacturers can achieve higher performance standards while meeting sustainability goals.

Renewable Energy Solutions

Renewable energy systems, such as wind turbines and solar panels, require materials capable of withstanding harsh environmental conditions. Tic-Tac Coating offers exceptional protection against wear and corrosion, ensuring consistent performance over time. Wind turbine blades, often exposed to abrasive particles and moisture, benefit from the coating’s ability to maintain surface integrity. Similarly, solar panel frames coated with this technology resist degradation caused by UV radiation and temperature fluctuations. These applications highlight the coating’s role in supporting the reliability and efficiency of renewable energy infrastructure.

Ningbo VET Energy Technology Co., Ltd: Advancing Tic-Tac Coating Technology

Visão geral da empresa

Ningbo VET Energy Technology Co., Ltd stands as a leader in material innovation, specializing in advanced coating technologies. The company has built a reputation for delivering high-performance solutions tailored to the needs of modern industries. With a focus on research and development, it consistently pushes the boundaries of material science. Its state-of-the-art facilities and expert team enable the creation of cutting-edge products that meet the demands of aerospace, automotive, and renewable energy sectors. By prioritizing quality and sustainability, the company has established itself as a trusted partner for businesses worldwide.

Contributions to Coating Innovation

The company has made significant strides in advancing Tic-Tac Coating technology. Its proprietary methods enhance the durability and versatility of composite materials, ensuring superior performance under extreme conditions. By integrating titanium carbide into its coatings, Ningbo VET Energy Technology Co., Ltd has set new benchmarks for wear resistance and thermal stability. These innovations have transformed industries by enabling lightweight designs without compromising strength. The company’s commitment to continuous improvement has also led to the development of environmentally friendly processes, reducing waste and energy consumption during production.

Future Developments in Tic-Tac Coating

The future of Tic-Tac Coating technology holds immense potential, driven by the company’s forward-thinking approach. Emerging trends in nanotechnology, biotechnology, and cognitive technologies are expected to converge, paving the way for groundbreaking advancements. Experts predict that the second generation of nanotechnology will introduce adaptive structures and actuators, enhancing coating performance. The anticipated third generation may bring robotic devices and guided assemblies, further revolutionizing the field. Ningbo VET Energy Technology Co., Ltd remains at the forefront of these developments, investing in research to harness these innovations and deliver next-generation solutions.

Nota: The company’s dedication to innovation ensures that it will continue to shape the future of material protection, setting new standards for performance and sustainability.

Metallization methods often fail to meet the durability and sustainability demands of modern industries. Tic-Tac Coating addresses these challenges by offering superior corrosion resistance, enhanced mechanical performance, and lightweight protection. The table below illustrates its transformative impact compared to other coatings:

| Tipo de revestimento | Resistência à corrosão | Mechanical Performance | Aplicações |

|---|---|---|---|

| Ni-P-Si3N4 | Superior | Enhanced | Magnesium alloys in hostile environments |

| Ni-P-CeO2 | Moderado | Improved | General composite applications |

| Ni-P-TiO2 | Baixo | Standard | Various industrial uses |

| Ni-P-Al2O3 | Lowest | Basic | Limited applications |

Ningbo VET Energy Technology Co., Ltd continues to lead the way in advancing this technology. Its innovative solutions redefine composite material protection, ensuring industries achieve both performance and sustainability goals.

FAQ

What makes Tic-Tac Coating superior to traditional metallization methods?

Tic-Tac Coating offers enhanced durability, lightweight protection, and superior adhesion to composites. It outperforms metallization in wear resistance, thermal stability, and environmental sustainability.

Can Tic-Tac Coating be customized for specific industries?

Yes, Tic-Tac Coating can be tailored to meet the unique requirements of industries like aerospace, automotive, and renewable energy, ensuring optimal performance in diverse applications.

How does Ningbo VET Energy Technology Co., Ltd contribute to Tic-Tac Coating innovation?

The company pioneers advanced coating techniques, integrating titanium carbide for superior performance. Its commitment to R&D ensures cutting-edge solutions for modern industrial challenges.