Silicon carbide (SiC) coating is essential in minimizing industrial carbon emissions, thanks to its superior thermal properties that significantly boost energy efficiency across various industries. For example, CVD SiC Coating applied to turbine blades in aviation enhances fuel efficiency by 15%, cutting down 23,000 tons of CO2 emissions annually per Boeing 787 engine. Likewise, in coal-fired power plants, SiC Coatings improve heat transfer efficiency, leading to a reduction of 50,000 tons of coal consumption annually per 1GW capacity. Advanced techniques such as CVD SiC Coating, TAC Coating, and CVD TAC Coating further elevate performance, supporting global sustainability initiatives. Ningbo VET Energy Technology Co., Ltd is at the forefront of these innovative coating solutions.

Key Takeaways

- SiC Coating helps industries use energy better and cut costs.

- New SiC Coating methods, like CVD and sputtering, make products last longer and work better for greener production.

- Using SiC Coating lets industries waste less and save energy, meeting worldwide eco-friendly goals.

SiC Coating and Energy Efficiency

Thermal Performance Improvements

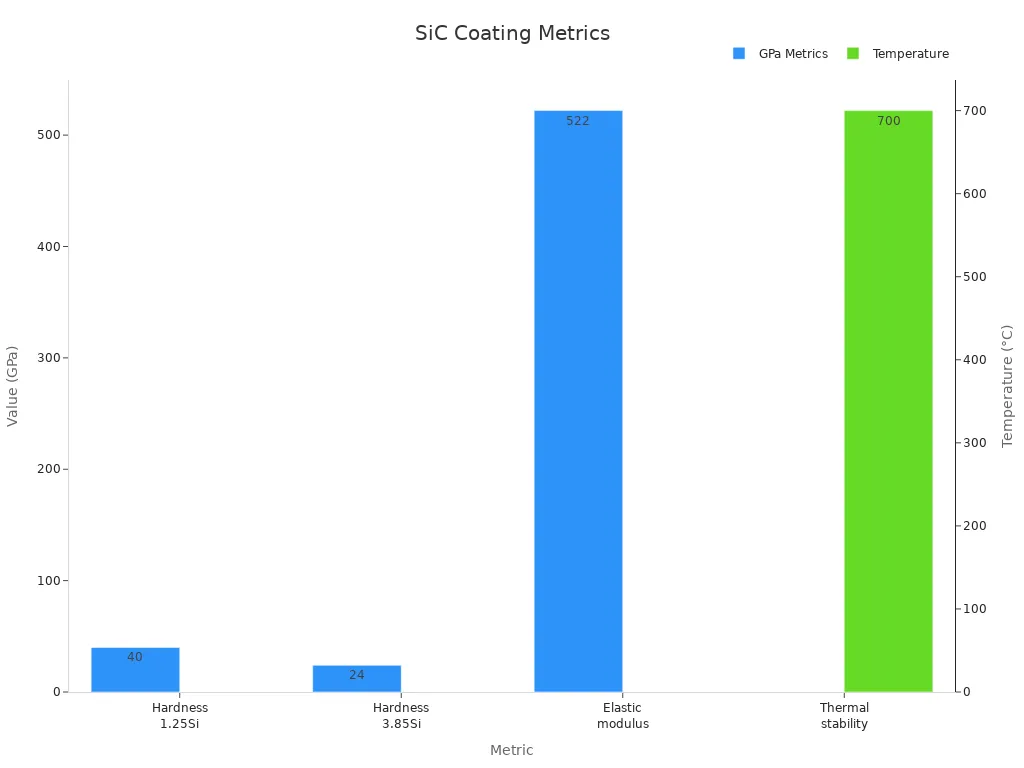

SiC Coating enhances thermal stability and durability, making it ideal for high-temperature environments. Its ability to withstand temperatures up to 700 °C ensures consistent performance under extreme conditions. The coating’s hardness varies based on silicon content, with 1.25 at.% Si achieving 40 GPa and 3.85 at.% Si reducing to 24 GPa. This adaptability allows manufacturers to tailor coatings to specific applications, optimizing thermal resistance and mechanical strength.

| Metric | Value |

|---|---|

| Thermal stability | Up to 700 °C |

| Hardness (1.25 at.% Si) | Increased to 40 GPa |

| Hardness (3.85 at.% Si) | Decreased to 24 GPa |

| Elastic modulus | 522 GPa |

| Wear rate | Decreased after annealing |

The elastic modulus of 522 GPa further highlights the material’s rigidity, ensuring minimal deformation under stress. These properties collectively contribute to improved thermal performance, reducing energy losses and enhancing operational efficiency.

Energy Savings in High-Temperature Applications

SiC Coating plays a pivotal role in energy conservation across industries. In high-temperature applications, such as power generation and industrial furnaces, the coating minimizes heat loss by improving thermal conductivity. This efficiency translates into reduced fuel consumption, lowering operational costs and carbon emissions. For instance, coal-fired power plants equipped with SiC Coating experience significant reductions in coal usage, contributing to cleaner energy production.

The automotive and aerospace sectors also benefit from SiC Coating’s energy-saving capabilities. By enhancing the thermal performance of engine components, the coating reduces fuel consumption and extends the lifespan of critical parts. Ningbo VET Energy Technology Co., Ltd has developed advanced SiC Coating solutions that optimize energy efficiency, supporting industries in their transition toward sustainable practices.

Sustainable Manufacturing Benefits

SiC Coating not only improves product performance but also promotes sustainable manufacturing. Its durability reduces the need for frequent replacements, minimizing waste and conserving resources. The coating’s wear resistance, which improves after annealing, ensures longer service life for coated components, aligning with circular economy principles.

Manufacturers adopting SiC Coating benefit from streamlined production processes that consume less energy and generate fewer emissions. This innovation supports global sustainability goals by reducing the environmental impact of industrial operations. Ningbo VET Energy Technology Co., Ltd continues to lead the way in developing SiC Coating technologies that prioritize both performance and sustainability.

Innovations in SiC Coating Techniques

Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is a widely adopted technique for producing high-quality SiC Coating. This method involves the chemical reaction of gaseous precursors on a heated substrate, forming a thin, uniform layer of silicon carbide. CVD excels in creating coatings with exceptional thermal stability, oxidation resistance, and material interface control. These properties make it ideal for applications in high-temperature environments and semiconductor manufacturing.

| Performance Metric | Description |

|---|---|

| Thermal Stability | The SiC coating maintains substrate stability in high-temperature environments. |

| Oxidation Resistance | Provides protection against oxidation in high-temperature conditions. |

| Material Interface Control | Ensures consistent properties and structures of the grown semiconductor films. |

| Impurity Contamination Reduction | Reduces reactions with corrosive gases, maintaining high purity of the substrate. |

CVD also ensures high purity by minimizing impurity contamination during the coating process. Ningbo VET Energy Technology Co., Ltd has pioneered advancements in CVD techniques, delivering SiC Coating solutions that meet the stringent demands of modern industries.

Sputtering Methods

Sputtering methods offer another innovative approach to SiC Coating. This physical vapor deposition technique involves bombarding a target material with high-energy particles, causing atoms to eject and deposit onto a substrate. Sputtering is highly efficient, producing coatings with precise thickness control and excellent adhesion.

| Coating Material | Elastic Modulus (GPa) | Friction Coefficient | Critical Load (N) |

|---|---|---|---|

| HfN | 224 | 0.44 | 41 |

| VN | 205 | 0.62 | 34 |

| Bilayer (15 nm) | Up to 351 | 0.15 | 72 |

The table above highlights the superior mechanical properties achieved through sputtering, particularly with bilayer coatings, which exhibit an elastic modulus of up to 351 GPa and a low friction coefficient of 0.15. These attributes enhance the durability and performance of SiC Coating in demanding applications. Ningbo VET Energy Technology Co., Ltd continues to refine sputtering methods, ensuring optimal results for industrial clients.

Sol-Gel Processes

The sol-gel process represents a cost-effective and versatile method for producing SiC Coating. This technique involves the transition of a liquid “sol” into a solid “gel” to form a thin film. Recent studies have demonstrated significant improvements in the mechanical and hydrophobic properties of SiC coatings produced through sol-gel processes.

For instance, the addition of precondensed DEDMS has increased Young’s modulus from 3 to 4 GPa and hardness from 0.55 to 0.70 GPa. Furthermore, hydrophobicity has been enhanced, with contact angles reaching up to 102°, making these coatings suitable for applications requiring water resistance. The sol-gel process also offers flexibility in tailoring coating properties to specific requirements, supporting diverse industrial applications.

Ningbo VET Energy Technology Co., Ltd leverages sol-gel technology to deliver high-performance SiC Coating solutions that align with sustainability goals and industry needs.

SiC Coating Applications Across Industries

Semiconductor Industry

SiC Coating plays a pivotal role in advancing semiconductor manufacturing processes. Its exceptional thermal stability and durability make it indispensable in applications like Rapid Thermal Processing (RTP) and Chemical Vapor Deposition (CVD).

| Application Area | Description |

|---|---|

| Rapid Thermal Processing (RTP) | SiC coatings are crucial for improved thermal management and reduced processing times. |

| CVD/PECVD Applications | SiC coatings enhance reliability and efficiency in semiconductor processing. |

SiC-coated graphite susceptors are increasingly utilized due to their ability to withstand extreme temperatures without degradation. Research highlights that SiC films, produced via CVD, exhibit excellent conformality and no void formation at the SiC/Si interface. This ensures high performance and reliability in semiconductor devices. As the demand for efficient and precise semiconductor processing grows, the adoption of SiC Coating continues to rise.

Automotive and Aerospace Sectors

The automotive and aerospace industries rely on SiC Coating for its superior resistance to high temperatures, wear, and corrosion. In the automotive sector, these coatings enhance the efficiency and durability of components, particularly in electric and hybrid vehicles. SiC Coating improves the performance of battery systems and power electronics, contributing to the development of sustainable transportation solutions.

In aerospace, SiC Coating ensures the longevity and reliability of critical components like turbine blades and engine parts. Its exceptional thermal stability allows these parts to operate under extreme conditions, reducing maintenance needs and improving fuel efficiency. These advancements align with the industry’s goals of reducing emissions and enhancing operational efficiency.

Renewable Energy Systems

SiC Coating significantly impacts renewable energy systems by improving the performance of power devices. Its high-temperature capability and faster switching speeds enhance power conversion efficiency.

| Benefit | Description |

|---|---|

| Higher Efficiency | SiC power devices improve power conversion efficiency due to faster switching speeds. |

| Reduced Size | Smaller transformers and capacitors can be used, leading to a more compact system. |

| Lower Cooling Requirements | SiC’s high temperature capability reduces the need for extensive cooling systems, decreasing overall size and cost. |

These benefits make SiC Coating an essential component in solar inverters, wind turbines, and other renewable energy technologies. By enabling compact and efficient designs, it supports the transition to cleaner energy sources while reducing the environmental footprint of energy systems.

Environmental Impact of SiC Coating Innovations

Waste Reduction and Product Longevity

SiC Coating innovations contribute significantly to waste reduction by enhancing the durability of coated materials. The coating’s exceptional wear resistance minimizes the need for frequent replacements, reducing industrial waste. In biomedical applications, SiC coatings mitigate corrosion on titanium implants, extending their lifespan and improving performance. Dental prosthetics and implants benefit from the coating’s high strength and biocompatibility, ensuring long-term reliability. Studies have shown that SiC coatings reduce corrosion effects on dental ceramics, enhancing their durability over time. These advancements align with sustainability goals by promoting product longevity and reducing material waste across industries.

Emission Reductions in Manufacturing

Manufacturing processes incorporating SiC Coating technologies achieve notable reductions in emissions. The coating’s thermal efficiency minimizes energy consumption during production, lowering greenhouse gas emissions. By improving heat transfer and reducing energy losses, SiC Coating supports cleaner manufacturing practices. Industries adopting these technologies experience decreased reliance on fossil fuels, contributing to global efforts to combat climate change. Ningbo VET Energy Technology Co., Ltd has developed advanced SiC Coating solutions that optimize manufacturing efficiency while prioritizing environmental sustainability.

Circular Economy Contributions

SiC Coating innovations play a vital role in advancing circular economy principles. The coating’s durability ensures extended product lifecycles, reducing the need for raw material extraction and manufacturing. Its wear resistance supports the reuse and recycling of coated components, minimizing waste generation. In renewable energy systems, SiC Coating enables compact designs that require fewer resources, further supporting circular economy goals. By fostering resource efficiency and reducing environmental impact, SiC Coating technologies contribute to a sustainable industrial ecosystem.

SiC Coating technologies have revolutionized industrial sustainability by enhancing energy efficiency, reducing emissions, and promoting product longevity.

Industries must embrace these innovations to achieve environmental goals and drive progress.

Ningbo VET Energy Technology Co., Ltd continues to lead advancements in SiC Coating, delivering solutions that align with global sustainability initiatives and industrial needs.

FAQ

What industries benefit the most from SiC Coating technology?

Industries like semiconductors, automotive, aerospace, and renewable energy benefit significantly. SiC Coating enhances durability, thermal efficiency, and sustainability in these sectors.

How does SiC Coating contribute to sustainability?

SiC Coating reduces energy consumption, minimizes waste, and extends product lifespans. These factors align with global sustainability goals and circular economy principles.

What makes Ningbo VET Energy Technology Co., Ltd a leader in SiC Coating?

The company pioneers advanced SiC Coating techniques like CVD and sputtering. Their innovations prioritize performance, energy efficiency, and environmental sustainability.

Tip: For more details on SiC Coating applications, explore the sections above.