Evaluating key factors when purchasing SiC coated components is essential to ensure optimal performance, cost efficiency, and reliability. As the SiC wafer defect inspection market is projected to expand from USD 3.2 billion in 2024 to USD 6.5 billion by 2034, industries such as electric vehicles increasingly require stringent quality assessments for CVD SiC coating, SiC coating, TAC coating, and advanced CVD TAC coating technologies.

Key Takeaways

- Focus on how pure and flawless the SiC coatings are. Pure coatings work better and last longer, while fewer flaws mean fewer problems.

- Choose suppliers who follow strict quality checks. This helps keep the coating even and reliable, saving money over time.

- Check if the SiC coated parts can handle heat and shocks. Strong coatings last longer in tough conditions, making them great for hard jobs.

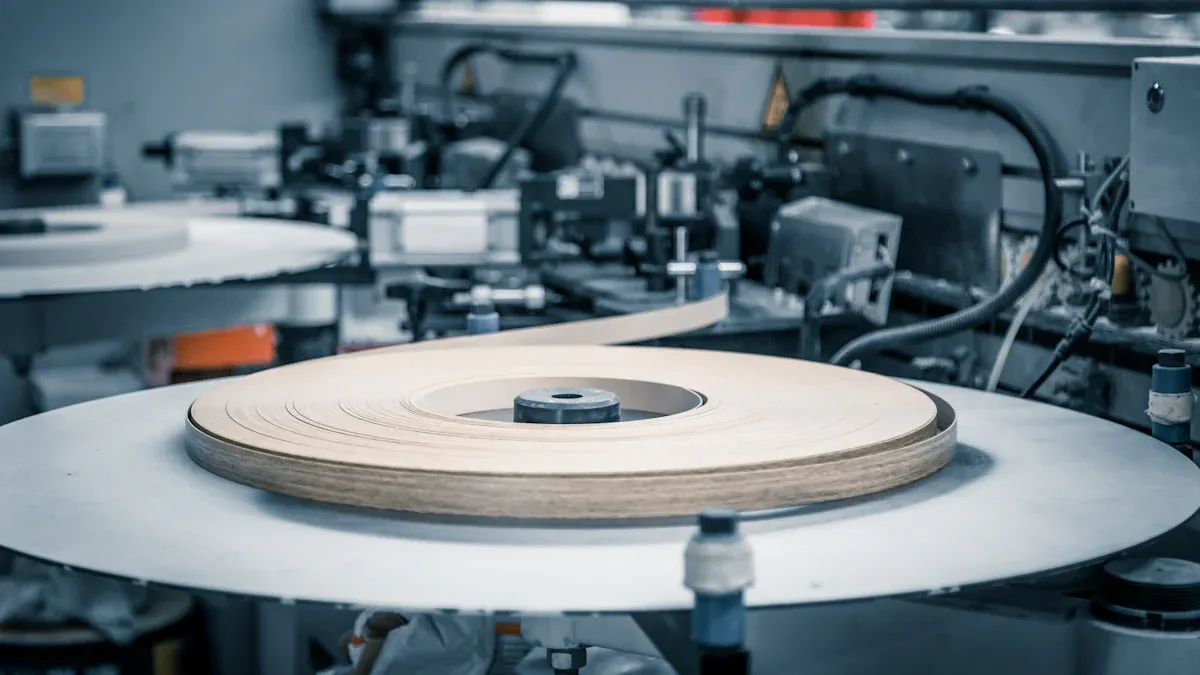

Material Quality of SiC Coated Components

Purity and Defect Density of the Coating

The purity and defect density of SiC coatings significantly influence their performance and reliability. High-purity coatings ensure better thermal and mechanical properties, while low defect density minimizes the risk of failure under extreme conditions. Advanced analytical techniques, such as Raman Spectroscopy, have demonstrated the importance of evaluating stoichiometry and crystallinity in SiC coatings. For instance, sharp peaks at 796 cm⁻¹ and 972 cm⁻¹ in Raman spectra indicate high crystallinity, confirming the absence of second-phase silicon or carbon.

Scanning Electron Microscopy (SEM) further highlights the role of defect density. Coatings with nano-sized pores exhibit lower density than theoretical values, which can compromise their structural integrity. Manufacturers like Ningbo VET Energy Technology Co., Ltd prioritize stringent quality checks to ensure their SiC coated components meet industry benchmarks.

The following table summarizes key elemental purity levels that define high-quality SiC coatings:

| Element | ppm |

|---|---|

| Sodium | < 0.05 |

| Copper | < 0.01 |

| Aluminum | < 0.04 |

| Iron | < 0.01 |

These purity levels contribute to improved uniformity, material consistency, and extended component lifetimes. They also enhance chip yields by optimizing photoluminescence properties, making them ideal for applications in demanding industries.

Thickness and Uniformity of the SiC Coating

The thickness and uniformity of SiC coatings directly impact their performance in high-stress environments. Uniform coatings ensure consistent protection against thermal and mechanical stresses, while optimal thickness enhances durability without compromising flexibility. Industry standards recommend a typical film thickness of 100 µm, as shown in the table below:

| Property | Units | Value |

|---|---|---|

| Typical film thickness | µm | 100 |

| Surface roughness | µm | 2.5 |

Uniformity in coating thickness also reduces the likelihood of weak points that could lead to premature wear or failure. Advanced manufacturing processes, such as those employed by Ningbo VET Energy Technology Co., Ltd, utilize precision techniques to achieve consistent thickness and surface smoothness. These processes ensure that SiC coated components deliver reliable performance across various applications, from semiconductor manufacturing to aerospace engineering.

Tip: When evaluating SiC coated components, prioritize suppliers who adhere to strict quality control measures. This ensures coatings meet both thickness and uniformity standards, providing long-term value and reliability.

Performance Characteristics of SiC Coated Components

Thermal Resistance and Shock Resistance

SiC coated components excel in environments requiring high thermal resistance and shock stability. Their ability to withstand extreme temperatures and sudden thermal fluctuations makes them indispensable in industries such as aerospace, automotive, and semiconductor manufacturing.

Empirical studies highlight the superior performance of SiC coatings under thermal stress. Ablation tests conducted under an oxyacetylene flame for 120 seconds demonstrated that SiC coatings remained intact, showing no surface cracks or erosion. This underscores their effectiveness in maintaining structural integrity under harsh conditions. Additionally, nonisothermal oxidation tests revealed significant weight loss reductions in coated samples compared to uncoated ones. For instance:

- Coated samples (PC-SiC and SS-SiC) exhibited mass ablation rates of 2.17 x 10^-23 g/s and 9.52 x 10^-23 g/s, respectively.

- These rates represent reductions of 84.1% and 29.6% compared to uncoated samples.

The following table summarizes key performance metrics:

| Test Description | Result |

|---|---|

| Thermal oxidation stability | High stability observed |

| Thermal shock stability | High stability observed |

| Adhesion to substrates | Good adhesion noted |

These results highlight the reliability of SiC coated components in applications requiring consistent performance under thermal and mechanical stress. Manufacturers like Ningbo VET Energy Technology Co., Ltd leverage advanced coating technologies to ensure their products meet these demanding requirements.

Tip: When selecting SiC coated components, prioritize those with proven thermal and shock resistance to ensure long-term durability and performance.

Mechanical Strength and Hardness

Mechanical strength and hardness are critical factors that determine the durability and wear resistance of SiC coated components. These properties enable the components to withstand high-pressure environments and mechanical loads without deformation or failure.

Comparative studies reveal the impact of different processing techniques on the mechanical properties of SiC coatings. High-Pressure Torsion (HPT) significantly improves hardness and strength by refining grains and eliminating residual porosity. In contrast, Spark Plasma Sintering (SPS) offers moderate improvements but results in lower ultimate tensile strength due to higher defect levels.

| Processing Technique | Effect on Hardness | Effect on Strength |

|---|---|---|

| High-Pressure Torsion (HPT) | Significant improvement due to grain refinement and elimination of residual porosity | Increased strength through Hall–Petch relationship |

| Spark Plasma Sintering (SPS) | Moderate improvement | Lower ultimate tensile strength compared to HPT due to higher defects |

Microtensile tests further demonstrate that HPT composites outperform SPS in ultimate tensile strength, thanks to reduced defects and enhanced microstructural properties. These findings emphasize the importance of selecting SiC coated components processed using advanced techniques to maximize mechanical performance.

Note: SiC coated components with superior mechanical strength and hardness offer extended lifespans and reduced maintenance costs, making them a cost-effective choice for demanding applications.

Application Suitability of SiC Coated Components

Compatibility with Extreme Operating Conditions

SiC coated components demonstrate exceptional performance in extreme environments, making them ideal for applications requiring high heat and pressure resistance. Their ability to maintain structural integrity under harsh conditions has been proven in various industries. For example, the Venus Lander (LLISSE) operated unprotected for 60 days at 460 °C and 9.3 MPa, showcasing the reliability of SiC electronics in extreme heat and pressure. Similarly, prototype SiC chips have performed effectively at temperatures exceeding 400 °C, highlighting their potential for future applications in demanding environments.

The aerospace sector has also benefited from SiC coated components. These materials enable compact integrated subsystems to function reliably without environmental sheltering, even at temperatures above 400 °C. The table below summarizes key performance highlights across different application areas:

| Application Area | Conditions (°C, MPa) | Performance Highlights |

|---|---|---|

| Venus Lander (LLISSE) | 460 °C, 9.3 MPa | Operated unprotected for 60 days, showcasing SiC electronics’ capability in extreme heat and pressure. |

| Prototype SiC Chips | ≥ 400 °C | Comparable complexity to 1970s silicon ICs, indicating potential for future applications in extreme environments. |

| Aerospace Systems | > 400 °C | Potential for compact integrated subsystems without environmental sheltering requirements, emphasizing reliability in harsh conditions. |

Tip: Industries requiring components for extreme operating conditions should prioritize SiC coated materials for their proven durability and reliability.

Resistance to Corrosion and Wear

SiC coated components offer superior resistance to corrosion and wear, making them indispensable in environments exposed to abrasive forces or chemical reactions. Their dense microstructure and high hardness prevent surface degradation, ensuring long-term performance. In chemical processing plants, SiC coatings protect equipment from corrosive substances, reducing maintenance costs and downtime.

In addition, SiC coated materials excel in applications involving high-speed mechanical wear, such as turbine blades and cutting tools. Their ability to withstand repeated stress without losing structural integrity enhances operational efficiency. Manufacturers like Ningbo VET Energy Technology Co., Ltd utilize advanced coating technologies to ensure their products meet stringent corrosion and wear resistance standards.

Note: Selecting SiC coated components with high corrosion and wear resistance ensures extended lifespans and reduced operational costs, making them a cost-effective choice for demanding industries.

Manufacturing Standards for SiC Coated Components

Compliance with Industry Standards

Adherence to industry standards ensures the reliability and safety of SiC coated components. Manufacturers must comply with globally recognized benchmarks, such as ISO 9001 for quality management systems and ASTM standards for material testing. These certifications validate that the components meet stringent requirements for performance, durability, and safety.

For SiC coated components, compliance with these standards guarantees consistent quality across production batches. It also ensures compatibility with demanding applications in industries like aerospace, automotive, and semiconductors. Leading manufacturers, including Ningbo VET Energy Technology Co., Ltd, prioritize compliance to deliver products that meet or exceed customer expectations.

Tip: Always verify that suppliers hold relevant certifications. This step ensures the components align with industry-specific requirements and deliver optimal performance.

Quality Control and Inspection Processes

Robust quality control and inspection processes are essential for producing high-performance SiC coated components. Advanced techniques, such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), play a critical role in detecting defects and ensuring coating uniformity. These methods help identify inconsistencies in thickness, purity, and adhesion, which could compromise the component’s performance.

Manufacturers like Ningbo VET Energy Technology Co., Ltd implement multi-stage inspections to maintain high standards. These inspections include raw material analysis, in-process monitoring, and final product testing. By employing such rigorous measures, they ensure that every SiC coated component meets precise specifications and performs reliably in its intended application.

Note: Choosing a supplier with a proven track record in quality control minimizes the risk of defects and enhances the longevity of the components.

Supplier Reputation and Reliability

Track Record and Customer Feedback

A supplier’s track record serves as a critical indicator of their reliability and expertise. Companies with a history of delivering high-quality SiC coated components consistently demonstrate their ability to meet industry demands. Examining past projects and client portfolios provides valuable insights into their performance. Suppliers with experience in diverse industries, such as aerospace, automotive, and semiconductors, often possess the technical knowledge required for complex applications.

Customer feedback further validates a supplier’s reputation. Positive reviews and testimonials highlight their commitment to quality and service. Independent platforms, industry forums, and case studies offer unbiased evaluations of a supplier’s capabilities. Manufacturers like Ningbo VET Energy Technology Co., Ltd have earned recognition for their exceptional products and customer-centric approach, making them a trusted choice for SiC coated components.

Tip: Prioritize suppliers with a proven track record and strong customer feedback to ensure consistent quality and reliability.

Certifications and Accreditations of Suppliers

Certifications and accreditations reflect a supplier’s adherence to industry standards and best practices. Compliance with ISO 9001, for instance, ensures robust quality management systems. Similarly, ASTM certifications validate the material properties and performance of SiC coated components. These credentials guarantee that the supplier meets stringent requirements for safety, durability, and reliability.

Suppliers like Ningbo VET Energy Technology Co., Ltd emphasize compliance with global standards. Their certifications underscore their commitment to delivering high-quality products that meet or exceed customer expectations. Choosing accredited suppliers minimizes risks and ensures compatibility with demanding applications.

Note: Always verify a supplier’s certifications to confirm their commitment to quality and compliance with industry benchmarks.

Customization Options for SiC Coated Components

Tailored Solutions for Specific Applications

Customization plays a vital role in ensuring SiC Coated components meet the unique demands of specific industries. Manufacturers offer tailored solutions to address application-specific requirements, such as extreme temperature resistance or enhanced mechanical strength. For example, components designed for aerospace applications may require coatings optimized for high thermal stability, while semiconductor manufacturing demands coatings with superior purity and uniformity.

Suppliers like Ningbo VET Energy Technology Co., Ltd collaborate closely with clients to understand their operational challenges. This approach allows them to develop customized SiC Coated components that align with precise specifications. By leveraging advanced technologies, they ensure the coatings deliver optimal performance in diverse environments.

Tip: Businesses should prioritize suppliers who offer tailored solutions to maximize the efficiency and reliability of their components.

Flexibility in Design and Specifications

Flexibility in design and specifications enhances the adaptability of SiC Coated components across various applications. Manufacturers provide options for adjusting coating thickness, surface roughness, and substrate compatibility to meet specific operational needs. This flexibility ensures the components perform reliably under different conditions, from high-pressure environments to corrosive settings.

Leading suppliers, including Ningbo VET Energy Technology Co., Ltd, utilize state-of-the-art manufacturing techniques to achieve precise customization. Their ability to modify designs and specifications ensures the components integrate seamlessly into existing systems. This adaptability reduces downtime and enhances overall productivity.

Note: Selecting suppliers with flexible design capabilities ensures the components meet exact requirements, minimizing risks and maximizing performance.

Cost-Effectiveness of SiC Coated Components

Balancing Initial Cost with Long-Term Value

Investing in SiC coated components often involves higher upfront costs compared to traditional materials. However, their long-term financial benefits outweigh the initial expenditure. These components exhibit exceptional durability and performance, reducing the frequency of replacements and operational disruptions. A comparative analysis reveals that the payback period for SiC components is shorter than that of superalloys, offering faster returns on investment.

Financial reports highlight the economic viability of SiC coated components. Sensitivity analyses demonstrate that ceramic matrix composite (CMC) blades, which incorporate SiC coatings, maintain a positive net present value (NPV) across various discount rates. This indicates their ability to deliver consistent financial returns under different economic conditions. Businesses seeking to optimize their operational budgets can benefit significantly from the long-term value these components provide.

Tip: Companies should evaluate the total cost of ownership rather than focusing solely on initial expenses. This approach ensures a more accurate assessment of the financial advantages offered by SiC coated components.

Maintenance and Replacement Costs

SiC coated components excel in reducing maintenance and replacement costs. Their superior resistance to wear, corrosion, and thermal stress minimizes the need for frequent repairs. This durability translates into lower downtime and increased productivity for industries relying on high-performance equipment.

Studies show that CMCs, which include SiC coatings, offer longer operational lifespans compared to traditional materials. This extended lifespan contributes to higher NPV and internal rate of return (IRR), making them a cost-effective choice for demanding applications. Additionally, the reduced maintenance requirements lower overall operating costs, enhancing profitability over time.

Manufacturers like Ningbo VET Energy Technology Co., Ltd focus on delivering SiC coated components that combine durability with cost efficiency. Their advanced coating technologies ensure that businesses achieve significant savings in maintenance and replacement expenses.

Note: Selecting SiC coated components with proven durability can lead to substantial cost savings, making them an ideal choice for industries prioritizing long-term financial performance.

Delivery and Lead Times for SiC Coated Components

Availability of Standard and Custom Components

The availability of both standard and custom SiC coated components plays a critical role in meeting industry demands. Standard components are often pre-manufactured and readily available, making them ideal for applications requiring quick deployment. These components typically adhere to common specifications, ensuring compatibility across a wide range of systems.

Custom components, on the other hand, cater to unique operational requirements. Industries such as aerospace and semiconductors often require tailored solutions to address specific challenges. Leading suppliers, including Ningbo VET Energy Technology Co., Ltd, offer extensive customization options. Their ability to modify coating thickness, substrate materials, and surface properties ensures that clients receive components optimized for their applications.

Tip: Businesses should evaluate whether their needs align with standard offerings or require custom solutions. This ensures timely procurement without compromising performance.

Timeliness of Order Fulfillment

Timely order fulfillment is essential for maintaining operational efficiency. Delays in delivery can disrupt production schedules and lead to financial losses. Reliable suppliers prioritize streamlined logistics and efficient manufacturing processes to minimize lead times.

Ningbo VET Energy Technology Co., Ltd exemplifies this commitment by leveraging advanced production techniques and robust supply chain management. Their ability to deliver both standard and custom components within agreed timelines has earned them a reputation for reliability. Additionally, their transparent communication ensures clients remain informed about order progress, reducing uncertainty.

Note: Partnering with suppliers known for timely delivery helps businesses avoid costly delays and maintain seamless operations.

Technical Support and After-Sales Service

Pre-Sales Consultation and Guidance

Effective pre-sales consultation ensures customers select the most suitable SiC coated components for their applications. Reputable suppliers, such as Ningbo VET Energy Technology Co., Ltd, provide expert advice tailored to specific operational needs. Their technical teams analyze customer requirements, offering recommendations that optimize performance and efficiency.

Pre-sales guidance often includes material selection, design customization, and compatibility assessments. These services help businesses avoid costly errors and ensure seamless integration into existing systems. For instance, suppliers may suggest adjustments to coating thickness or substrate materials to enhance durability under extreme conditions. This proactive approach minimizes risks and maximizes the value of the investment.

Tip: Collaborating with suppliers who offer comprehensive pre-sales support can significantly improve decision-making and operational outcomes.

Warranty and Post-Sales Support

Robust warranty and post-sales support enhance the reliability and longevity of SiC coated components. Leading manufacturers prioritize customer satisfaction by offering extensive after-sales services. These include global support hotlines, spare parts availability, and annual service reviews.

The following table highlights key features and benefits of effective post-sales support:

| Feature | Benefit |

|---|---|

| Global support hotline | Fast resolution of issues through immediate access to support. |

| Expert advice | Optimization of processes leading to improved performance. |

| Spare parts availability | Ensures long-term reliability with parts available for ten years post-discontinuation. |

| Online documentation support | Provides easy access to necessary information for equipment use. |

| Annual service review | Regular assessments to maintain high performance and reliability. |

| Rapid delivery of spare parts | Minimizes downtime, ensuring continuous operation of equipment. |

| Staff training | Ensures proper equipment use, contributing to uptime and performance. |

Manufacturers like Ningbo VET Energy Technology Co., Ltd excel in delivering these services. Their commitment to rapid response and long-term support ensures uninterrupted operations for their clients.

Note: Selecting suppliers with strong post-sales support guarantees peace of mind and maximizes the return on investment.

Environmental and Safety Considerations

Eco-Friendly Manufacturing Practices

Sustainability has become a critical factor in modern manufacturing. Leading suppliers of SiC coated components, such as Ningbo VET Energy Technology Co., Ltd, adopt eco-friendly practices to minimize environmental impact. These practices include reducing energy consumption, recycling materials, and using non-toxic chemicals during production.

For instance, advanced coating processes often utilize closed-loop systems to capture and reuse waste materials. This approach reduces landfill contributions and conserves valuable resources. Additionally, many manufacturers invest in renewable energy sources, such as solar or wind power, to lower their carbon footprint.

Tip: Businesses prioritizing sustainability should partner with suppliers committed to green manufacturing. This choice not only supports environmental goals but also aligns with global regulatory trends.

Compliance with Safety Standards and Certifications

Safety compliance ensures the reliability and integrity of SiC coated components. Manufacturers must adhere to stringent safety standards, such as ISO 45001 for occupational health and safety and RoHS (Restriction of Hazardous Substances) for environmental protection. These certifications validate that the production processes and materials meet global safety benchmarks.

Ningbo VET Energy Technology Co., Ltd exemplifies this commitment by maintaining compliance with international safety standards. Their certifications guarantee that their components are free from hazardous substances and safe for use in critical applications.

| Certification | Purpose |

|---|---|

| ISO 45001 | Ensures workplace safety and health |

| RoHS | Restricts hazardous substances in products |

Note: Verifying a supplier’s safety certifications helps businesses mitigate risks and ensures compliance with industry regulations.

Purchasing SiC coated components requires careful evaluation of ten critical factors, including material quality, performance, and cost-effectiveness. These considerations ensure reliability and long-term value. The market, growing at 15.20%, is driven by energy efficiency and electric vehicle adoption. Reputable suppliers like Ningbo VET Energy Technology Co., Ltd deliver tailored solutions for diverse needs.

| Factor | Description |

|---|---|

| Market Growth Rate | 15.20% during the forecast period |

| Growth Driver 1 | Growing demand from the oil and gas industry |

| Growth Driver 2 | Growing emphasis on energy efficiency |

| Growth Driver 3 | Increasing adoption of electric vehicles |

Tip: Partnering with trusted manufacturers ensures high-quality components and seamless integration into demanding applications.

FAQ

What industries benefit the most from SiC coated components?

Industries like aerospace, automotive, semiconductors, and chemical processing benefit significantly. These components excel in extreme conditions, offering durability, thermal resistance, and corrosion protection.

How does SiC coating improve component performance?

SiC coatings enhance thermal stability, mechanical strength, and wear resistance. They also protect against corrosion, ensuring reliable performance in demanding environments.

Why choose Ningbo VET Energy Technology Co., Ltd for SiC coated components?

Ningbo VET Energy Technology Co., Ltd delivers high-quality, customized SiC coated components. Their advanced manufacturing processes and certifications ensure reliability and long-term value.

Tip: Always verify supplier certifications and customer feedback to ensure quality and reliability when purchasing SiC coated components.