Preventing Downtime: Best Practices for Maintaining Graphite Seals and Bushings

Prevent downtime with best practices for graphite bearing/bushing maintenance. Learn about material selection, lubrication, and damage prevention for efficiency.

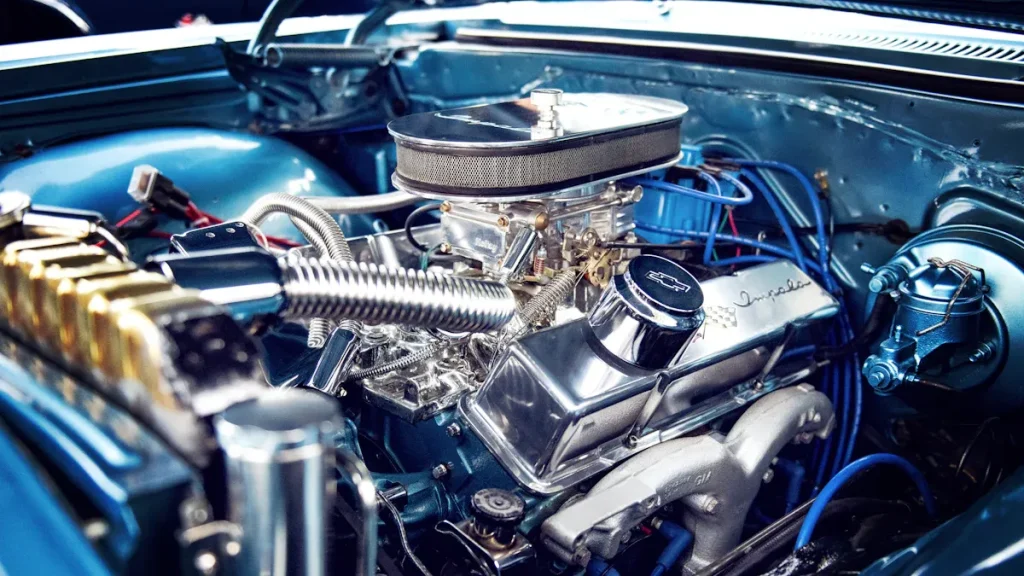

How to Extend the Lifespan of Crankshaft Pulleys with Advanced Graphite Coatings

Extend crankshaft pulley lifespan with advanced graphite coatings. Reduce wear, resist heat, and improve efficiency for durable, low-maintenance performance.

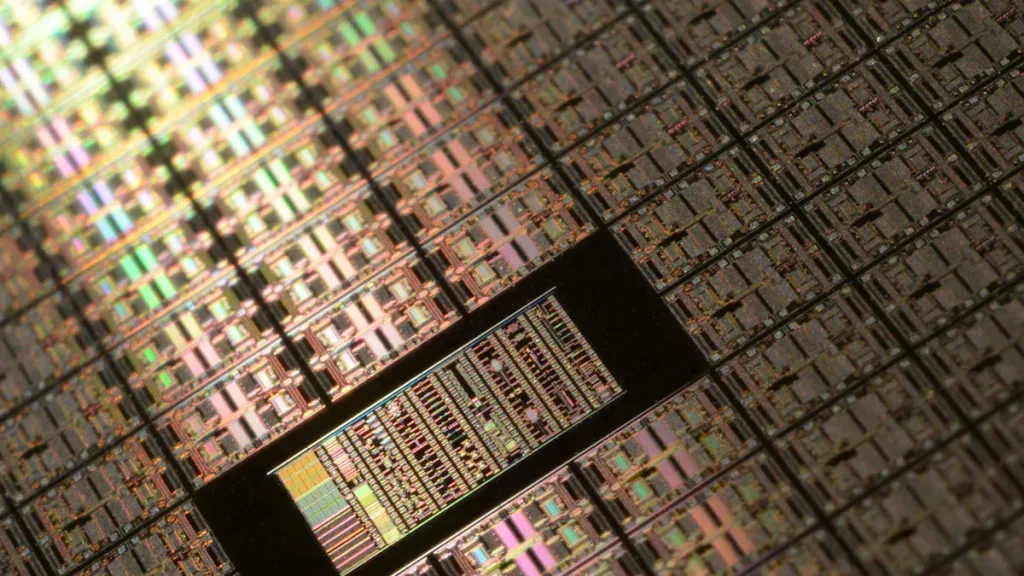

The Role of MOCVD Epitaxial Parts in Ensuring Semiconductor Efficiency in 2025

MOCVD epitaxial parts ensure precise layer deposition, boosting semiconductor efficiency with uniformity, scalability, and reliability for advanced devices.

How Can Graphite Bolts Enhance Performance in Harsh Conditions

Graphite bolts enhance performance in harsh conditions with heat resistance, corrosion resistance, and durability, making them ideal for demanding industries.

Future-Proofing Automotive Tech: SiC Coating for EV Charging Components

SiC Coating enhances EV charging components by improving thermal management, durability, and efficiency, addressing heat, corrosion, and electrical stress challenges.

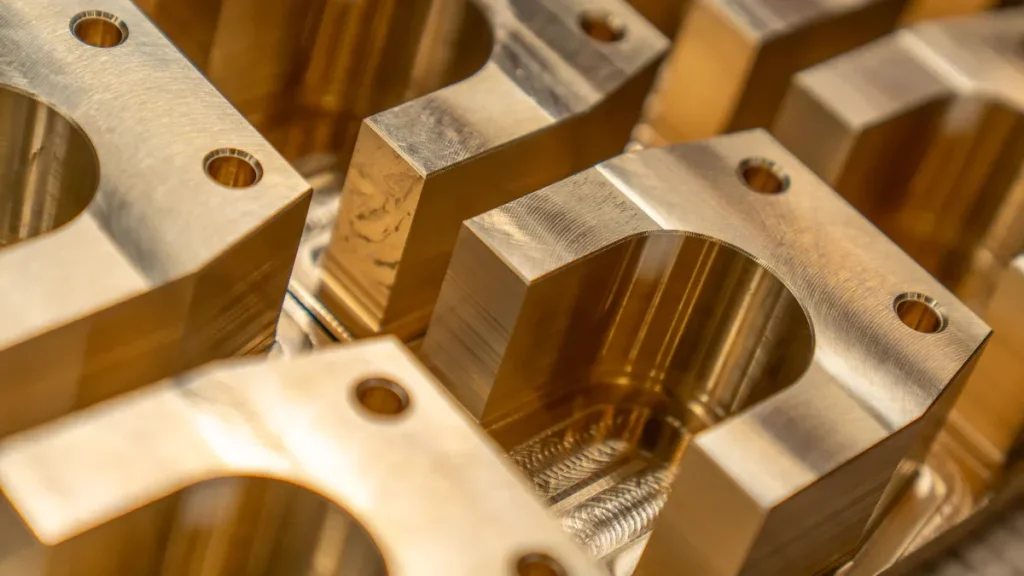

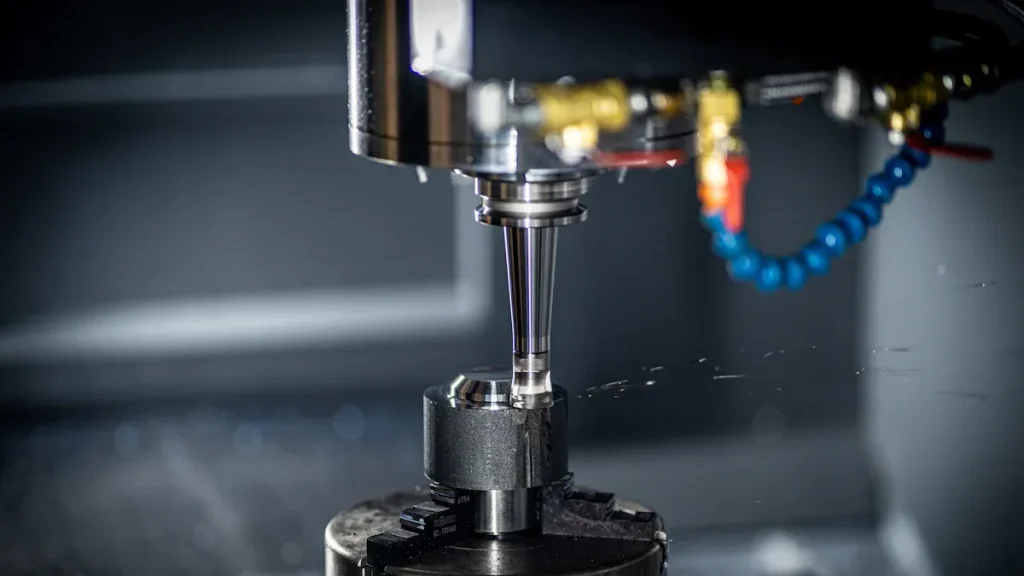

Innovations in Graphite Mold Design for High-Precision Semiconductor Manufacturing

Innovations in graphite mold design boost precision, durability, and efficiency in semiconductor manufacturing, meeting the demands of advanced technologies.

Graphite Electrode vs. Traditional Electrodes: Cost-Efficiency in Lithium-Ion Battery Production

Graphite electrodes offer superior cost-efficiency, durability, and performance over traditional electrodes, making them ideal for lithium-ion battery production.

The Role of Graphite Rotors & Vanes in Energy-Efficient HVAC Systems

Graphite Rotors & Vanes boost HVAC energy efficiency with high thermal conductivity, lightweight design, and durability, reducing energy use and maintenance costs.

TaC Coating vs. SiC Coating: Which Is Better for Automotive Engine Parts?

TaC coatings excel in extreme heat and durability, while SiC coatings offer cost-effective versatility for automotive engine parts. Which suits your needs?

Innovations in Graphite Mold Design for High-Precision Semiconductor Manufacturing

Discover how advanced graphite mold designs improve precision, durability, and efficiency in semiconductor manufacturing, meeting high-performance demands.