Vidro resistente ao calor Carbon Crucible are specialized crucibles designed for high-temperature experiments and applications. They offer excellent heat resistance, chemical stability, and high purity, making them widely used in industries like metallurgy, ceramics, chemicals, and semiconductors.

Their production involves a complex process, including using high-purity materials like graphite and asphalt, undergoing high-temperature treatments, forming, sintering, annealing, grinding, and polishing to ensure top quality and performance.

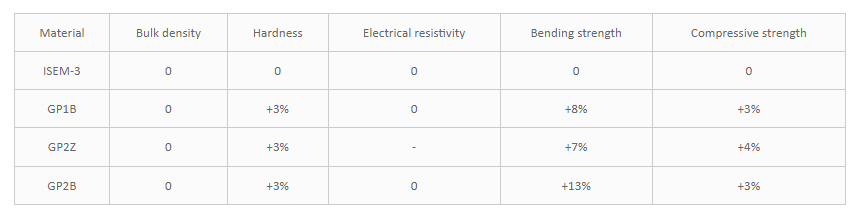

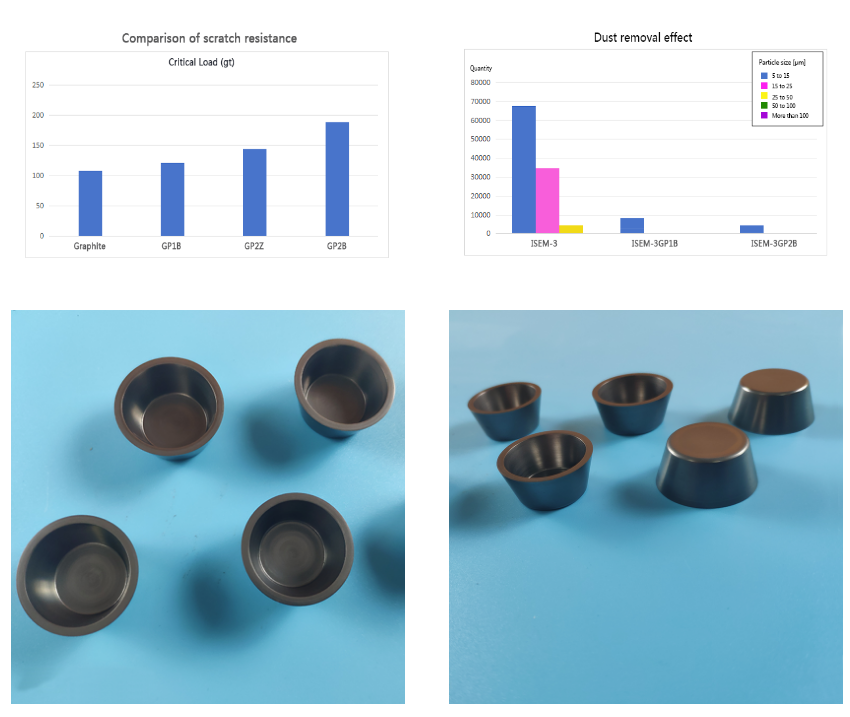

Vidro resistente ao calor Carbon Crucible features include compatibility with various graphite materials as substrates, maintaining the graphite substrate’s properties, reducing graphite dust formation, and offering improved scratch resistance and enhanced anti-friction durability.

We supply components for monocrystalline silicon drawing equipment, epitaxial growing parts, continuous casting dies, and glass seal fixtures. Let us know if you need more details!